The Importance of ROHS Testing: Flyaford’s Dedication to Quality and Compliance

At Flyaford, we understand that ROHS testing is crucial for ensuring the safety and environmental sustainability of our insulation products. As a leading manufacturer in the industry, our commitment to adhering to ROHS standards is integral to our mission of providing high-quality and reliable insulation solutions for various applications.

Understanding ROHS Compliance

ROHS testing is a regulatory requirement designed to limit the use of hazardous substances in electrical and electronic products. The ROHS directive restricts materials like lead, mercury, cadmium, and certain flame retardants, which can pose significant risks to both human health and the environment. At Flyaford, we prioritize compliance with these regulations to ensure that all our products, including the versatile SB 14 Series, meet the highest safety and environmental standards.

Our SB 14 Series is a prime example of Flyaford’s dedication to quality and compliance. These insulators are meticulously crafted to offer exceptional performance while adhering to strict ROHS guidelines. By ensuring that our products are free from harmful substances, we contribute to a safer environment and align with global sustainability efforts.

Flyaford’s SB 14 Series: Engineered for Excellence

The SB 14 Series stands out for its superior design and performance. Our composite Polymer Insulators are available in various diameters from 14mm to 60mm and heights from 14mm to 100mm, catering to a wide range of electrical applications. Whether used in low voltage or high voltage systems, these insulators deliver reliable support and insulation.

Key features of the SB 14 Series include:

● Temperature Resistance: Designed to function effectively in a temperature range from -40℃ to 140℃.

● Voltage Ratings: Suitable for both AC and DC applications, with voltage ratings from 560V to 5600V.

● Material Integrity: Incorporates copper and iron components for enhanced stability and secure installations.

Each SB 14 Series insulator undergoes rigorous ROHS testing to ensure it meets all necessary environmental and safety standards. Our comprehensive testing procedures evaluate the material's durability, Electrical insulation properties, and compliance with ROHS requirements. This ensures that our products not only perform reliably but also contribute to a greener, safer future.

Why Partner with Flyaford?

Choosing Flyaford means partnering with a company that values excellence and compliance. Our manufacturing facility is equipped with advanced MES systems and automation technology, which enhances product stability and quality control. With certifications like ISO9001, ISO14001, and IATF16949, we uphold rigorous standards in all our operations.

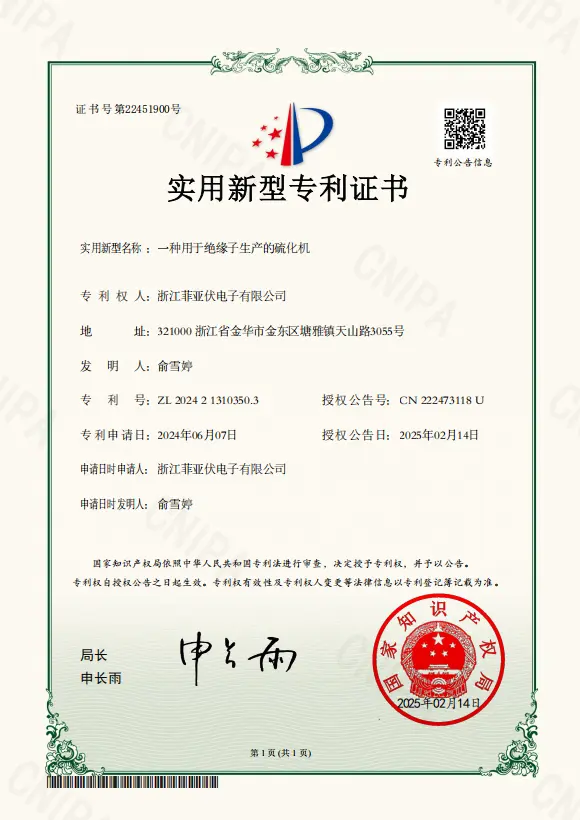

Flyaford’s innovation is reflected in our portfolio of 13 patents and ongoing research for new solutions. Our ability to provide customized insulators with a minimum order quantity of 100 pieces ensures flexibility and scalability for your needs. Whether you are a distributor or a buyer, our commitment to ROHS testing and product excellence makes Flyaford a trusted partner in the insulation industry.

Conclusion

Flyaford’s commitment to ROHS testing and compliance underscores our dedication to producing high-quality, environmentally responsible insulation solutions. The SB 14 Series exemplifies our focus on safety, performance, and sustainability. For distributors and partners seeking reliable and compliant insulation products, Flyaford offers unparalleled quality and innovation. Reach out to us today to explore how we can meet your specific needs and contribute to your success.