The Advantages of Composite Hollow Insulators for Electrical Systems

At Flyaford, we are dedicated to providing high-quality insulators that meet the evolving needs of the electrical industry. Our composite hollow insulators, specifically the EL Series, are designed to deliver exceptional performance and reliability. These insulators are essential for ensuring safe operation in various applications, from substations to rail systems.

Features of Flyaford Composite Hollow Insulators

The Flyaford EL Series composite hollow insulators boast impressive specifications. With heights ranging from 60 to 150 mm and diameters of 60 to 65 mm, these insulators are crafted from high-quality Bulk Molding Compound (BMC) and Dough Molding Compound (DMC). This choice of materials ensures that our composite hollow insulators exhibit exceptional durability and strength, making them suitable for demanding environments. These electrical Standoff Insulators provide robust support and insulation, which are critical for the safe operation of electrical equipment.

Application Versatility

Our composite hollow insulators are engineered to serve various applications effectively. They are particularly useful in low-tension insulators for rail insulation and as bus post insulators in substations. The versatility of these insulators ensures that they can adapt to different operational needs while maintaining their integrity and performance. With screw options ranging from M10 to M12, along with metal inserts made from copper and iron, we guarantee secure and reliable installations. The engineered design of Flyaford composite hollow insulators allows them to function optimally in environments with extreme temperatures, ranging from -40 to 140℃.

High Voltage Capabilities

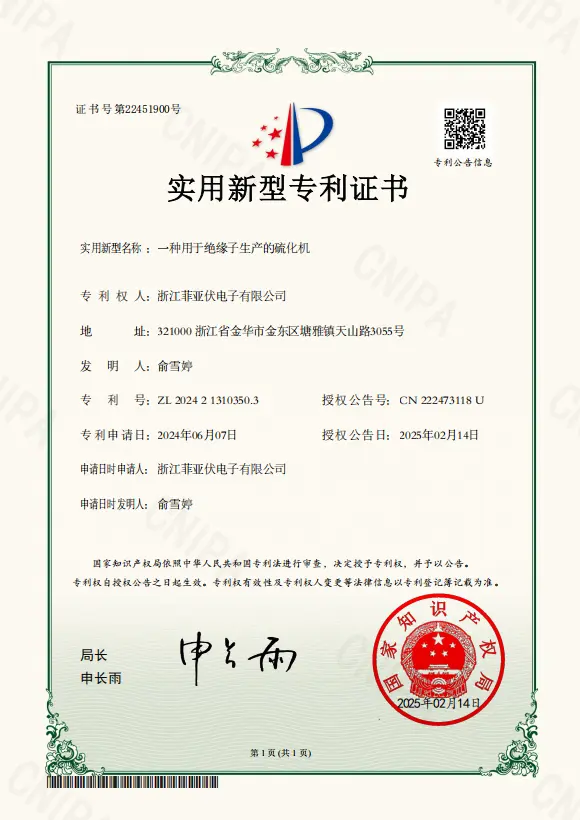

Flyaford composite hollow insulators are not just versatile; they are also designed for high-voltage applications. Rated for AC voltages from 2000 to 13800V and capable of withstanding voltages as high as 50000V, these insulators are ideal for environments where electrical safety is paramount. Our commitment to quality is reflected in the comprehensive testing each insulator undergoes, including resilience to temperature changes, withstand voltage, and flame retardancy. Through this rigorous testing, we ensure that our composite hollow insulators meet the highest industry standards, further validated by certifications such as CE, REACH, ELV, and SGS.

Quality Assurance and Support

At Flyaford, we believe that quality assurance goes hand in hand with customer support. Our composite hollow insulators are designed not only to meet but exceed expectations. We provide thorough documentation and support to help our customers understand the capabilities and applications of our products. Our commitment to quality is unwavering, and we strive to be a reliable partner for businesses seeking robust insulator solutions.

Conclusion

In summary, Flyaford's composite hollow insulators represent a blend of advanced engineering and material science, making them a top choice for various electrical applications. With features that ensure durability, versatility, and high voltage capacity, our EL Series insulators are designed to meet the demands of modern Electrical Systems. By choosing Flyaford, you can trust that you are investing in quality and performance, helping to ensure the safety and reliability of your electrical infrastructure. Let us support your projects with our industry-leading insulator solutions.