Revolutionizing Power Distribution with Flyaford’s Composite Hollow Core Insulators

When it comes to ensuring the efficiency and safety of power distribution networks, the role of a reliable composite hollow core insulator cannot be overstated. At Flyaford, we have dedicated years of research and innovation to perfecting our insulators, making them the industry standard for electrical cabinets, new energy vehicles, photovoltaic systems, and more. Our Composite Hollow Core Insulators are designed to withstand extreme conditions while maintaining performance, ensuring that your systems remain operational and secure.

The Evolution of Insulation Technology in Power Systems

Over the years, the power industry has seen significant advancements in insulation technology. Traditional insulators, while effective, often fell short when it came to durability and performance under extreme conditions. At Flyaford, we recognized the need for a more robust solution, leading to the development of our composite hollow core insulators. These insulators are engineered with advanced materials, such as BMC and DMC, to offer superior tensile strength, compressive resistance, and torque performance, making them ideal for high-stress applications.

Key Features of Flyaford’s Composite Hollow Core Insulators

Our Flyaford SM series drum insulators stand out for their versatility and reliability. Designed for optimal performance, these insulators offer a range of heights from 20mm to 76mm and A/F dimensions from 17mm to 50mm, accommodating various busbar configurations. The SM insulators are equipped with copper and iron screws ranging from M5 to M10, ensuring secure installations that enhance both safety and efficiency. With temperature ratings from -40℃ to 140℃ and AC/DC voltage ratings that meet the demands of modern Electrical Systems, our insulators are built to last.

Partnering with Flyaford for Reliable Power Solutions

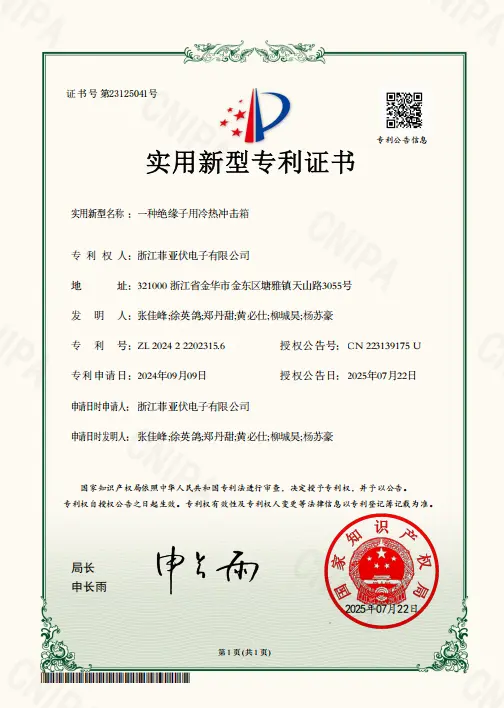

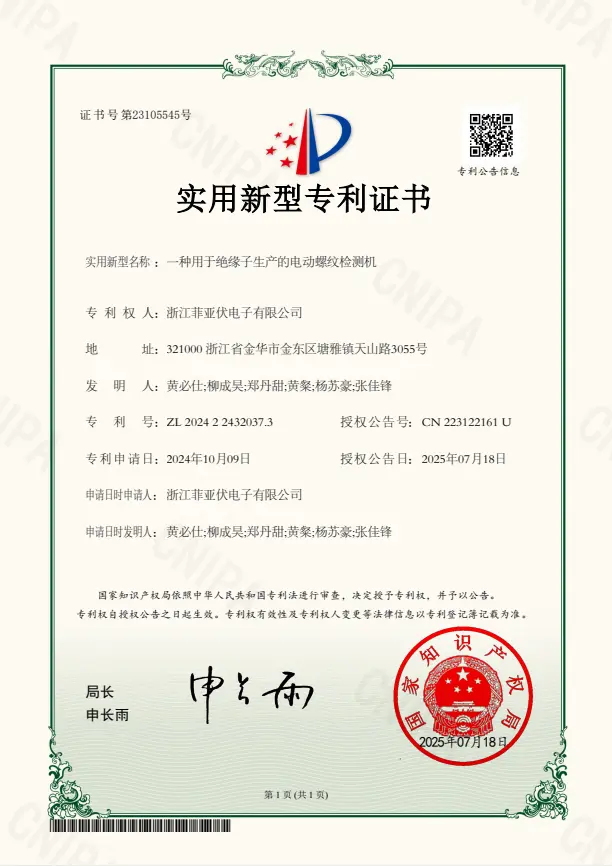

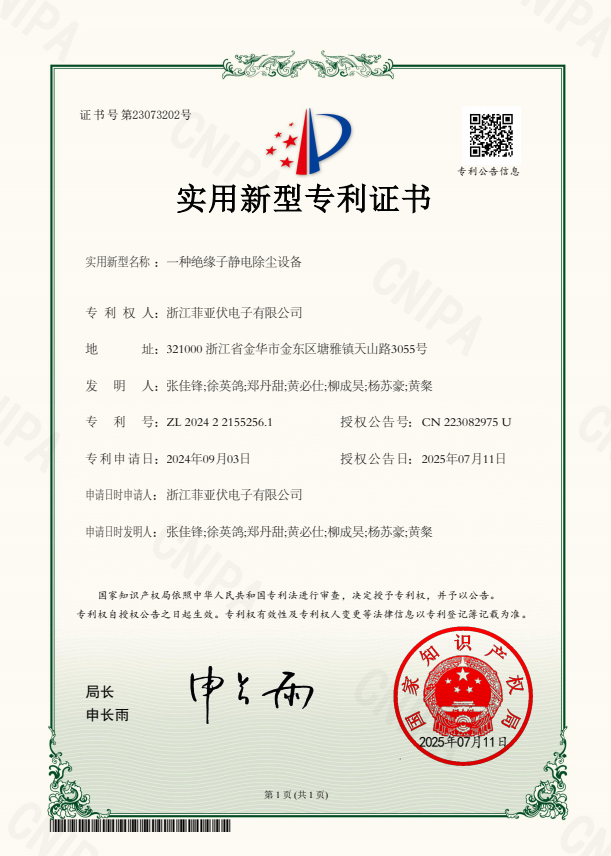

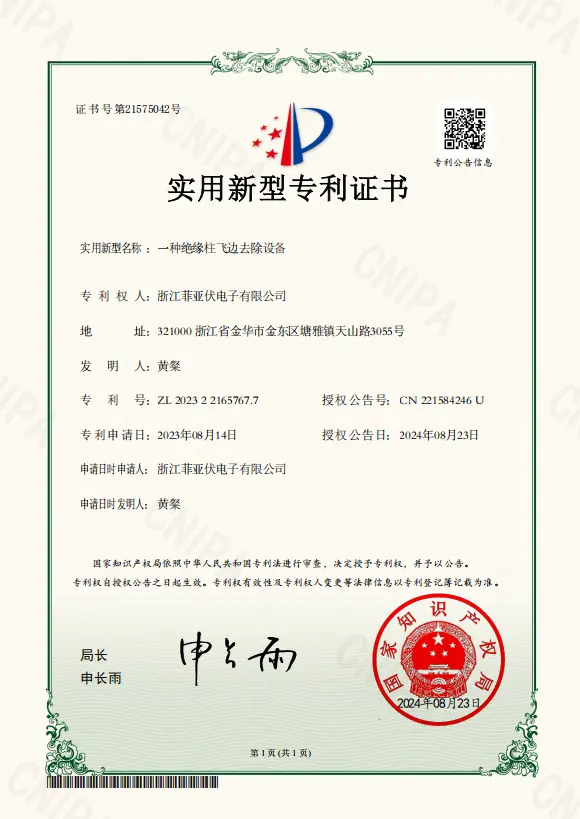

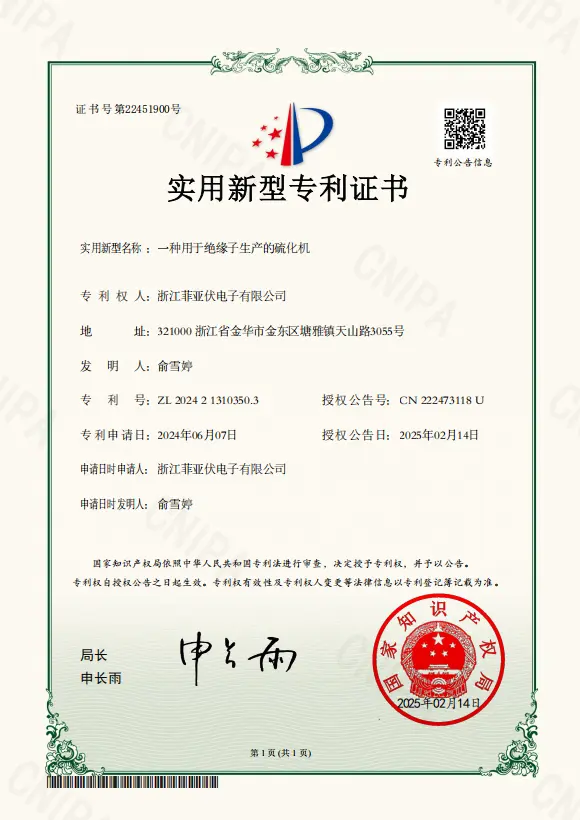

At Flyaford, we are more than just a supplier; we are your partner in power distribution. Our commitment to quality is reflected in our rigorous testing processes, which include thermal shock tests, low-high temperature tests, and ROHS compliance assessments. We take pride in our 13 patents and the continuous innovation that drives our product development. Whether you need customized insulator solutions or require a minimum order quantity of 100pcs, we are here to meet your needs with stable, high-end products that set the industry standard.

Conclusion

In a world where reliability and performance are paramount, Flyaford’s composite hollow core insulators offer a solution that is both innovative and dependable. By choosing Flyaford, you are investing in a future of safe, efficient, and long-lasting power distribution systems. Let’s work together to revolutionize your infrastructure with our cutting-edge insulation technology.