Innovative Bus Bar Insulators for Modern Applications: How Flyaford Leads the Way

At Flyaford, we understand that the quality of bus bar insulators is crucial for maintaining efficient and reliable electrical systems. Our range of bus bar insulators, including the versatile SM series, is engineered to meet the highest standards of performance and durability. By choosing Flyaford, you benefit from insulators designed to enhance your electrical infrastructure across various applications.

Key Advantages of Flyaford’s Bus Bar Insulators

High-Quality Material Construction: Our SM series drum insulators are produced using premium BMC and DMC materials, providing superior strength and insulation properties. These materials ensure that our insulators perform reliably in extreme temperatures and challenging environments.

Extensive Voltage and Temperature Range: With voltage ratings from 800V to 3000V AC and 1100V to 4200V DC, Flyaford’s insulators are suitable for a wide range of electrical applications. The ability to operate efficiently from -40℃ to 140℃ adds to their versatility.

Customizable Options: We offer a variety of sizes and configurations, including the SM 25 model, to meet specific project requirements. Our customizable solutions ensure that you get the right insulator for your unique needs.

Benefits of Choosing Flyaford’s Insulators

Enhanced Operational Efficiency: Flyaford’s bus bar insulators improve system efficiency by reducing energy losses and enhancing overall reliability. Our insulators help in maintaining consistent performance and minimizing disruptions.

Cost-Effective Solutions: By extending the lifespan of your electrical components and reducing maintenance needs, our insulators offer significant cost savings. Their robust design ensures long-term durability and reliability.

Wide Application Scope: Whether for high-speed rail systems, 5G communication, or solar energy projects, Flyaford’s insulators are designed to perform optimally across various sectors, providing dependable insulation and support.

Flyaford’s Industry-Leading Standards and Support

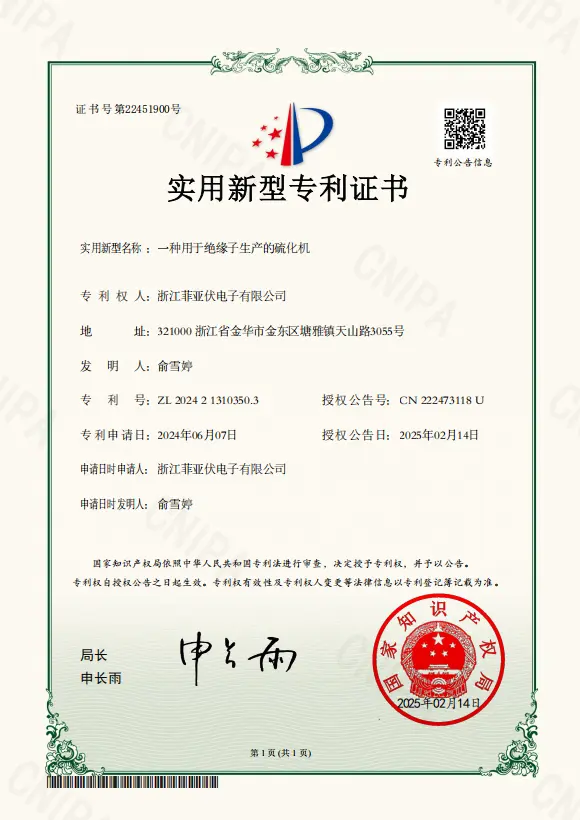

Stringent Quality Assurance: We adhere to rigorous testing protocols, including ROHS compliance and certification from ISO9001, ISO14001, and IATF16949. These standards guarantee that our insulators meet the highest quality and safety criteria.

Innovative Technology: Flyaford is committed to staying at the forefront of technological advancements. Our production processes are supported by advanced automation and MES systems, ensuring the precision and consistency of our insulators.

Dedicated Customer Service: Our team is dedicated to providing exceptional support throughout the product lifecycle. From initial consultation to post-sale service, we ensure that your needs are met with professionalism and expertise.

Conclusion

Flyaford’s bus bar insulators deliver exceptional performance, durability, and versatility for a variety of electrical applications. Our commitment to quality, innovation, and customer satisfaction makes us the ideal choice for your insulation needs. Contact us today to learn more about how our products can enhance your electrical systems and explore partnership opportunities with Flyaford.