Fortifying Safety Lines, Safeguarding Intelligent Manufacturing Development

To effectively implement the fire safety guideline of "Prevention First, Combination of Prevention and Fire Fighting" and address the specific fire safety requirements in the production process of electronic manufacturing enterprises, our company recently organized a special fire safety lecture and practical training session. Mr. Huang Can, General Manager of the company, all over 80 employees, and the safety management team participated in the entire event. Experts from Jinhua Fire and Rescue Detachment were specially invited to give on-site lectures and guidance.

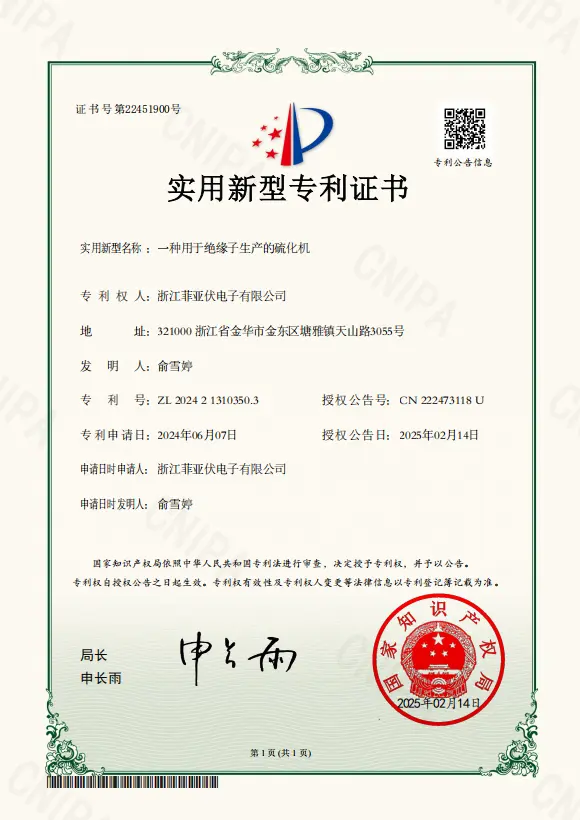

"As a national high-tech enterprise, our workshops are equipped with precision production equipment and involve polymer insulating materials. Fire safety is not only related to the lives of more than 80 employees but also underpins the production foundation for the transformation of the company's 18 patented technologies," Mr. Huang Can emphasized in his opening speech. Since its establishment in 2007, the company has always prioritized safety in its development. This event is a practical implementation of the concept of "simultaneous upgrading of digital production and safety management."

Fire experts delivered in-depth explanations based on the characteristics of the electronic manufacturing industry, focusing on key risk points such as the storage of insulating materials, the operation and maintenance of electrical equipment, and fire prevention in cleanrooms. In view of the company's production process characteristics for products like insulators, the experts specifically pointed out: "Although insulating materials have flame-retardant properties, the operating temperature must be strictly controlled during the high-temperature molding process. Dust accumulation around the FFU (Fan Filter Unit) in the workshop should be cleaned regularly to avoid potential fire hazards." Meanwhile, combining recent fire cases in electronic enterprises, they elaborated on the core requirements of the Code for Design of Clean Rooms regarding the division of fire compartments and the configuration of gas fire-extinguishing systems, and emphasized practical key points such as "setting up fire partitions for every 2,000 square meters and regularly testing the resistance of anti-static floors."

During the interactive Q&A session, an employee from the technical workshop asked about "how to put out fires in precision testing equipment." The experts clearly responded: "For high-value testing instruments, the IG-541 mixed gas fire-extinguishing system should be adopted to avoid equipment damage caused by water stains, which is consistent with the safety concept of 'high-temperature resistant materials' in the company's product research and development." Customized Fire Safety Manual for Electronic Enterprises was also distributed on-site, systematically sorting out standardized procedures for raw material storage, equipment inspection, and emergency response.

After the lecture, the practical drill was launched immediately. In the simulated scenario of "fire caused by aging electrical circuits in the molding workshop," under the guidance of the evacuation team, employees covered their mouths and noses with wet towels, bent down and evacuated along the route indicated by the photoluminescent signs, and all arrived at the safe assembly point within only 3 minutes. Subsequently, fire fighters demonstrated the operating essentials of fire extinguishers ("lift, pull, hold, squeeze") on-site. Employees were divided into groups to practice putting out oil pan fires, and technical backbones also conducted emergency activation drills for the heptafluoropropane fire-extinguishing system.

In his summary, Mr. Huang Can stated that the company will incorporate fire safety training into the "monthly safety mandatory course," establish an intelligent inspection mechanism for fire-fighting facilities in conjunction with the digital production system, and build a solid safety barrier through "theory + practice + technological prevention and control" to provide a strong guarantee for product supply in fields such as new energy vehicles and 5G communications.