0102030405

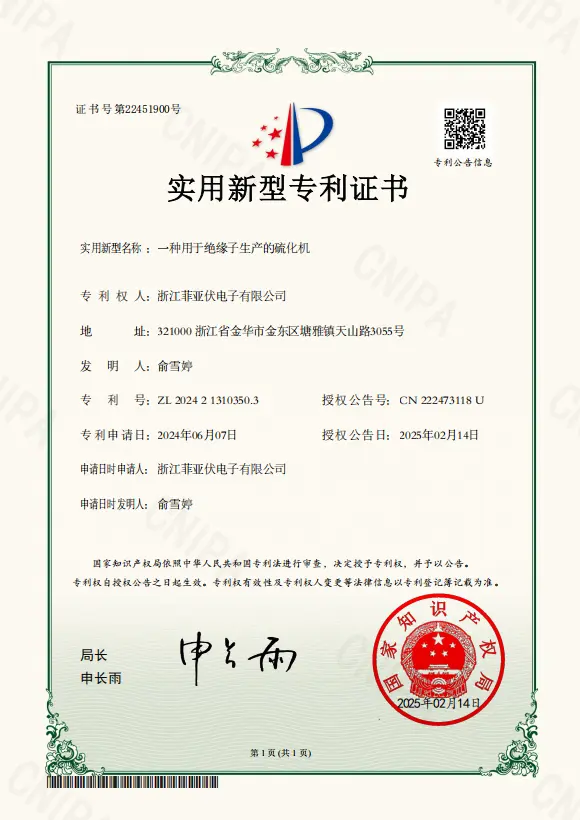

Flyaford Electronics wins utility model patent for insulator thermal shock chamber

2025-08-18

Recently, our company has successfully obtained the utility model patent certificate for an insulator thermal shock chamber. This achievement marks an important breakthrough in the research and development of insulator testing equipment in our company.

The patented insulator thermal shock chamber is mainly used for thermal shock tests of insulators and can meet relevant standards such as GB/T 19443 - 2017 "Definitions, Test Methods and Acceptance Criteria for Ceramic or Glass Insulator String Components for DC Systems of Overhead Line Insulators with Nominal Voltage Above 1500V" and GB/T 1001.1 - 2003 "Insulators for Overhead Lines with Nominal Voltage Above 1000V - Part 1: Definitions, Test Methods and Judgment Criteria for Ceramic or Glass Insulator Components for AC Systems".

The thermal shock chamber features a unique structural design with an upper-lower structure. The upper part is an air high-temperature zone, and the lower part is a cold water zone. The upper and lower parts are connected through a mechanical transmission structure. The internal size of the high-temperature zone is not less than IW450 × IH450 × ID450mm, and the internal size of the cold water zone is not smaller than that of the high-temperature zone. It can withstand the high-temperature gas pressure generated by the test sample to ensure that the box does not crack or deform.

In terms of temperature control, the temperature in the high-temperature zone can be precisely regulated within the range of +20°C to +200°C, with a temperature fluctuation of ≤±0.5°C, a temperature deviation of ≤±2°C, and a temperature uniformity of ≤2°C. Meanwhile, the equipment has the capability of rapid heating. Under no-load and no-heating conditions, it takes less than 50 minutes to heat from room temperature (RT) to +200°C.

In addition, the exterior of the thermal shock chamber is made of high-quality cold-rolled steel plate with plastic spraying treatment, and the plate thickness is not less than 1.0mm; the interior is made of high-quality stainless steel plate (SUS 304 2B CP type grinding processing), with a plate thickness of not less than 1.0mm; the thickness of the box body is ≥T 100mm, and high-efficiency heat-insulating superfine glass wool is used as the thermal insulation material, which effectively ensures the thermal insulation performance and durability of the equipment. The box door is equipped with high-temperature perspective glass, and the viewing window is not less than 250*250mm, facilitating the operator to observe the test process.

The blower adopts a single-suction multi-blade stainless steel axial flow fan, AC220V, 180W; the heater is of nickel-chromium alloy type, AC220V, 1KW. The circulation mode is forced hot air circulation with a horizontal laminar flow pattern. The temperature regulation adopts automatic adjustment of heating output power and PID adjustment, and is equipped with a high-precision K-type thermocouple as a sensor.

In terms of working mode, the high-temperature zone and the low-temperature zone can be automatically compared, and the specified temperature for insulator thermal shock can be automatically input. The tester heats up to the specified temperature and maintains it. After reaching the specified time, the bottom plate of the high-temperature zone is automatically opened, and the sample is sent to the cold water zone through a special mechanical mechanism. The valve plate of the cold water zone is opened to actively discharge water vapor. After the sample is cooled, it can be taken out of the tester through key operation. It is also equipped with a fully automatic insulator lifting test frame, which greatly improves the automation degree and efficiency of the test.

The acquisition of this patent is not only a recognition of our company's technological innovation capability, but also will further enhance our competitiveness in the research, development and production of insulators and related products. In the future, our company will continue to increase investment in research and development, committed to providing more high-quality and efficient products and solutions for the industry, and promoting the technological progress and development of the insulator industry.