BMC SB 14-20 Series Insulators: The Smart Choice for Power Systems

BMC SB 14-20 Series Insulators: The Smart Choice for Power Systems introduction

In terms of application fields, the SB series standoff insulators are mainly applied in cutting - edge areas such as battery packs of new - energy vehicles, energy storage systems, and photovoltaic inverters. In the battery packs of new - energy vehicles, they play a crucial role in ensuring the safe isolation of circuits. The SB series electrical insulators can effectively prevent current leakage, thus guaranteeing the stable operation of the entire battery system. With their excellent insulation performance, the SB series busbar insulators can operate stably in complex electrical environments and provide solid support for the normal operation of energy storage systems. As the core equipment of solar power generation systems, photovoltaic inverters need to convert direct current into alternating current, which generates a large amount of current and heat during the process. The SB series low-medium voltage insulators can effectively isolate circuits, prevent current interference and leakage, and at the same time withstand a certain high - temperature environment, ensuring the efficient conversion and stable operation of photovoltaic inverters.

However, different customers face a variety of complex installation environments when using these devices. Some customers may install the devices in outdoor environments with high temperature and high humidity, such as photovoltaic power stations in desert areas, where the temperature is extremely high during the day and the air may also contain a certain amount of sand and moisture. Customers have extremely high expectations for the high - temperature resistance, moisture resistance, and durability of the insulators. They hope that the insulators will not age or be damaged in extreme environments.

To meet these strict requirements of customers, our company has established a comprehensive and scientific quality inspection system. When customers raise questions or requirements regarding the reliability of the insulators, we will conduct a series of targeted reliability tests according to their specific needs. These tests include long - term operation tests in simulated high - temperature environments. By placing the insulators in a high - temperature test chamber and setting different temperature gradients and time periods, we detect the changes in performance indicators such as insulation resistance and dielectric constant of the insulators under high - temperature conditions. There are also tests in simulated humid environments, where we use professional humidity test equipment to control the environmental humidity and observe the surface conditions and electrical performance of the insulators under different humidity conditions. At the same time, we will conduct durability tests by simulating current shocks and mechanical vibrations in actual use to evaluate the performance stability of the insulators during long - term use. After the tests are completed, we will issue detailed and accurate reliability test reports.

BMC SB 14-20 Series Insulators: The Smart Choice for Power Systems specification

| Product features(Technical Data) | Meet ROHS 2.0 environmental requirements Colors, inserts, materials can be customized according to customer requirements |

| Type | SB series(SB-type hexagonal support insulators) |

| Product height | 14-100 mm |

| Product diameter | 14-20mm |

| Thread | M4-M8 |

| Insert material | brass, steel |

| Raw material | unsaturated resin (BMC/DMC) |

| MOQ | 100 pcs |

| Working temperature | -40-140℃ |

| Flame retardant grade | UL94 V0 (3mm) |

| Hot wire temperature | 960℃ |

| Operating voltage (AC) | 560-4000V |

| Working voltage (DC) | 800-5600V |

| Test items | low and high temperature test, pressure resistance, torque strength, tension, bending force, pressure, insulation resistance, ROHS, flame retardant |

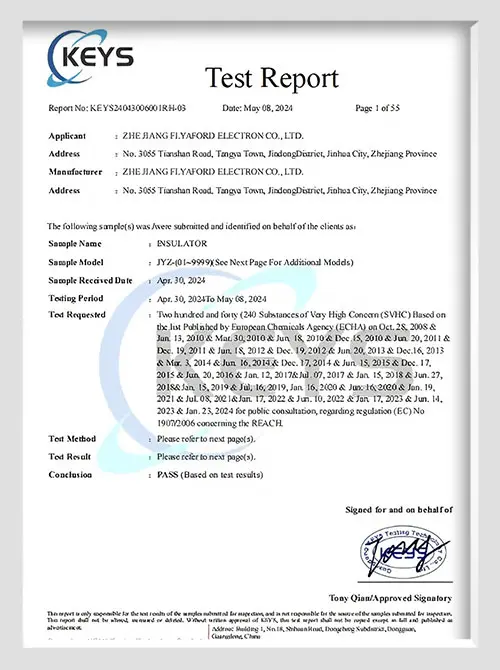

| Certificates | CE, REACH, ELV, SGS |

| Quality System | ISO9001, ISO14001, IATF16949 |

production workshop

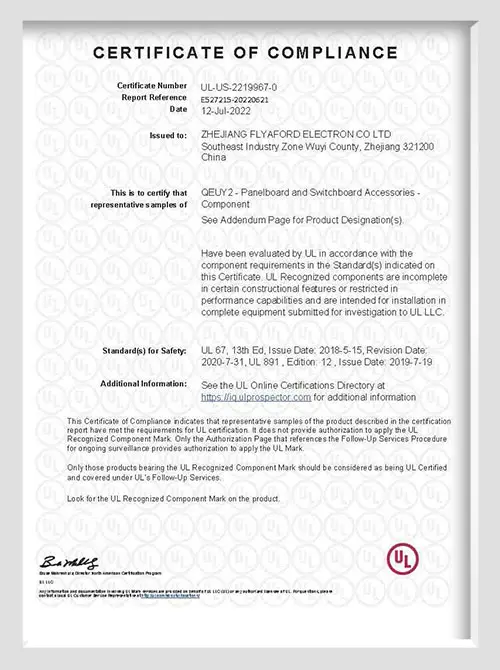

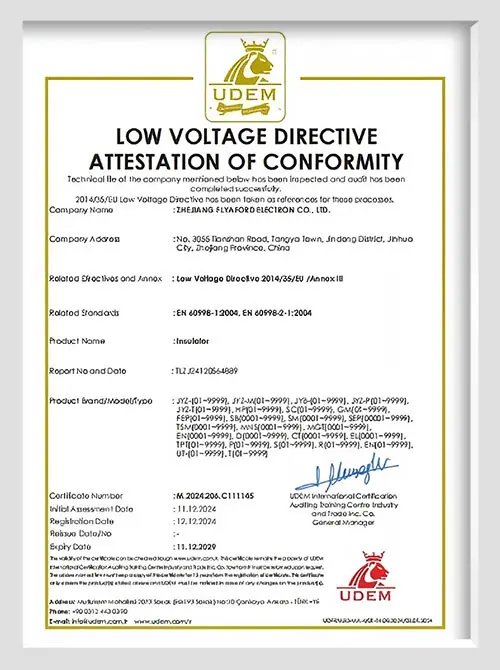

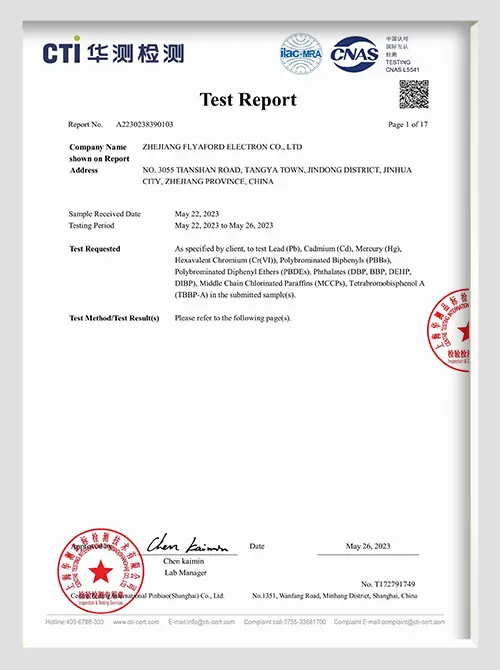

Product certification

UL, CE, ROHS, REACH, IATF16949, ISO9001, ISO14001, PSCR

UL

CE

IATF16949

ISO9001

ISO14001

PSCR

ROHS

REACH

Product packaging

Product application cas

Contact Us

SB Series Insulator

SB 14 Series

| Type | thread | Insert | BD | Tightening torque | Height | Nominal Volatage |

| Insert | Size | material | (mm) | (N.m) | (H)mm | (AC/DC) |

| SB1414 | M4 | brass | ≥4 | 2 | 14 | (560/800) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB1614 | M4 | brass | ≥4 | 2 | 16 | (640/900) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB2014 | M4 | brass | ≥6 | 2 | 20 | (800/1100) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥6 | 3 | |||

| M5 | steel | ≥6 | 4 | |||

| M6 | brass | ≥6 | 4 | |||

| M6 | steel | ≥6 | 5 | |||

| SB2514 | M4 | brass | ≥6 | 2 | 25 | (1000/1400) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥8 | 4 | |||

| M6 | steel | ≥8 | 5 | |||

| SB3014 | M4 | brass | ≥6 | 2 | 30 | (1200/1600) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB3514 | M4 | brass | ≥6 | 2 | 35 | (1400/1900) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB4014 | M4 | brass | ≥6 | 2 | 40 | (1600/2200) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB4514 | M4 | brass | ≥6 | 2 | 45 | (1800/2500) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB5014 | M4 | brass | ≥6 | 2 | 50 | (2000/2800) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 |

SB 16 Series

| Type | thread | Insert | BD | Tightening torque | Height | Nominal Volatage |

| Insert | Size | material | (mm) | (N.m) | (H)mm | (AC/DC) |

| SB1416 | M4 | brass | ≥4 | 2 | 14 | (560/800) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB1616 | M4 | brass | ≥4 | 2 | 16 | (640/900) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB2016 | M4 | brass | ≥6 | 2 | 20 | (800/1100) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥6 | 3 | |||

| M5 | steel | ≥6 | 4 | |||

| M6 | brass | ≥6 | 4 | |||

| M6 | steel | ≥6 | 5 | |||

| SB2516 | M4 | brass | ≥6 | 2 | 25 | (1000/1400) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥8 | 4 | |||

| M6 | steel | ≥8 | 5 | |||

| SB3016 | M4 | brass | ≥6 | 2 | 30 | (1200/1600) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB3516 | M4 | brass | ≥6 | 2 | 35 | (1400/1900) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB4016 | M4 | brass | ≥6 | 2 | 40 | (1600/2200) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB4516 | M4 | brass | ≥6 | 2 | 45 | (1800/2500) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB5016 | M4 | brass | ≥6 | 2 | 50 | (2000/2800) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 |

SB 18 Series

| Type | thread | Insert | BD | Tightening torque | Height | Nominal Volatage |

| (Insert) | Size | material | (mm) | (N.m) | (H)mm | (AC/DC) |

| SB1418 | M4 | brass | ≥4 | 2 | 14 | (560/800) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB1618 | M4 | brass | ≥4 | 2 | 16 | (640/900) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB2018 | M4 | brass | ≥6 | 2 | 20 | (800/1100) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥6 | 3 | |||

| M5 | steel | ≥6 | 4 | |||

| M6 | brass | ≥6 | 4 | |||

| M6 | steel | ≥6 | 5 | |||

| SB2518 | M4 | brass | ≥6 | 2 | 25 | (1000/1400) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥8 | 4 | |||

| M6 | steel | ≥8 | 5 | |||

| SB3018 | M4 | brass | ≥6 | 2 | 30 | (1200/1600) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB3518 | M4 | brass | ≥6 | 2 | 35 | (1400/1900) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB4018 | M4 | brass | ≥6 | 2 | 40 | (1600/2200) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB4518 | M4 | brass | ≥6 | 2 | 45 | (1800/2500) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 | |||

| SB5018 | M4 | brass | ≥6 | 2 | 50 | (2000/2800) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥8 | 3 | |||

| M5 | steel | ≥8 | 4 | |||

| M6 | brass | ≥10 | 4 | |||

| M6 | steel | ≥10 | 5 |

SB 20 Series

| Type | thread | Insert | BD | Tightening torque | Height | Nominal Volatage |

| (Insert) | Size | material | (mm) | (N.m) | (H)mm | (AC/DC) |

| SB1420 | M4 | brass | ≥4 | 2 | 14 | (560/800) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB1620 | M4 | brass | ≥4 | 2 | 16 | (640/900) |

| M4 | steel | ≥4 | 3 | |||

| M5 | brass | ≥4 | 3 | |||

| M5 | steel | ≥4 | 4 | |||

| M6 | brass | ≥4 | 4 | |||

| M6 | steel | ≥4 | 5 | |||

| SB2020 | M4 | brass | ≥6 | 2 | 20 | (800/1100) |

| M4 | steel | ≥6 | 3 | |||

| M5 | brass | ≥6 | 4 | |||

| M5 | steel | ≥6 | 5 | |||

| M6 | brass | ≥6 | 5 | |||

| M6 | steel | ≥6 | 6 | |||

| M8 | brass | ≥6 | 6 | |||

| M8 | steel | ≥6 | 8 | |||

| SB2520 | M5 | brass | ≥8 | 4 | 25 | (1000/1400) |

| M5 | steel | ≥8 | 6 | |||

| M6 | brass | ≥8 | 5 | |||

| M6 | steel | ≥8 | 8 | |||

| M8 | brass | ≥8 | 8 | |||

| M8 | steel | ≥8 | 10 | |||

| SB3020 | M5 | brass | ≥8 | 4 | 30 | (1200/1600) |

| M5 | steel | ≥8 | 6 | |||

| M6 | brass | ≥10 | 5 | |||

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB3520 | M5 | brass | ≥8 | 4 | 35 | (1400/1900) |

| M5 | steel | ≥8 | 6 | |||

| M6 | brass | ≥10 | 5 | |||

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB4020 | M5 | brass | ≥8 | 4 | 40 | (1600/2200) |

| M5 | steel | ≥8 | 6 | |||

| M6 | brass | ≥10 | 5 | |||

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB4520 | M5 | brass | ≥8 | 4 | 45 | (1800/2500) |

| M5 | steel | ≥8 | 6 | |||

| M6 | brass | ≥10 | 5 | |||

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB5020 | M5 | brass | ≥8 | 4 | 50 | (2000/2800) |

| M5 | steel | ≥8 | 6 | |||

| M6 | brass | ≥10 | 5 | |||

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 |

| Type | thread | Insert | BD | Tightening torque | Height | Nominal Volatage |

| (Insert) | Size | material | (mm) | (N.m) | (H)mm | (AC/DC) |

| SB5520 | M6 | brass | ≥10 | 5 | 55 | (2200/3000) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB6020 | M6 | brass | ≥10 | 5 | 60 | (2400/3300) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB6520 | M6 | brass | ≥10 | 5 | 65 | (2600/3600) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB7020 | M6 | brass | ≥10 | 5 | 70 | (2800/3900) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB7520 | M6 | brass | ≥10 | 5 | 75 | (3000/4200) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB8020 | M6 | brass | ≥10 | 5 | 80 | (3200/4500) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB8520 | M6 | brass | ≥10 | 5 | 85 | (3400/4800) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB9020 | M6 | brass | ≥10 | 5 | 90 | (3600/5100) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB9520 | M6 | brass | ≥10 | 5 | 95 | (3800/5400) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 | |||

| SB10020 | M6 | brass | ≥10 | 5 | 100 | (4000/5600) |

| M6 | steel | ≥10 | 8 | |||

| M8 | brass | ≥10 | 8 | |||

| M8 | steel | ≥10 | 12 |