Leave Your Message

In the ever-evolving world of electrical engineering, the role of

standoff insulators has become increasingly significant,

with the global insulator market projected to reach

$16.3 billion by 2026, according to a recent report by MarketsandMarkets.

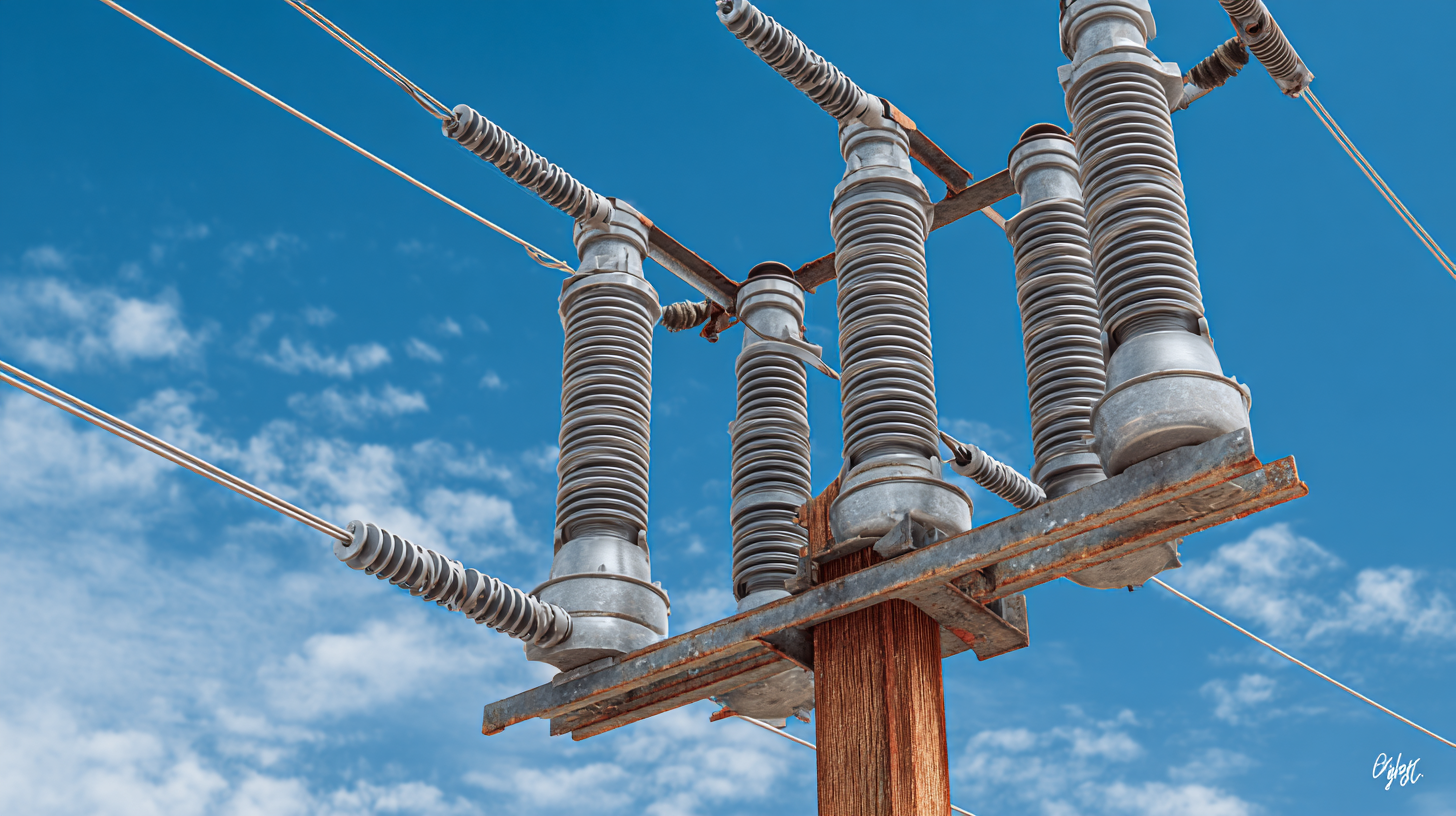

Standoff insulators, designed to support and insulate conductors while providing necessary clearance from structures,

are essential for enhancing safety and efficiency in electrical networks.

With advancements in materials and engineering, various innovative applications of standoff insulators are now emerging across multiple sectors,

including renewable energy, telecommunications, and transportation.

This blog will explore these unique applications, showcasing how standoff insulators are not only improving system reliability

but also contributing to sustainable practices by minimizing environmental impact and enhancing infrastructure resilience.

Prepare to delve into the remarkable ways in which this often-overlooked component is transforming the landscape of electrical systems today.

In the ever-evolving world of electrical engineering, the role of

standoff insulators has become increasingly significant,

with the global insulator market projected to reach

$16.3 billion by 2026, according to a recent report by MarketsandMarkets.

Standoff insulators, designed to support and insulate conductors while providing necessary clearance from structures,

are essential for enhancing safety and efficiency in electrical networks.

With advancements in materials and engineering, various innovative applications of standoff insulators are now emerging across multiple sectors,

including renewable energy, telecommunications, and transportation.

This blog will explore these unique applications, showcasing how standoff insulators are not only improving system reliability

but also contributing to sustainable practices by minimizing environmental impact and enhancing infrastructure resilience.

Prepare to delve into the remarkable ways in which this often-overlooked component is transforming the landscape of electrical systems today.

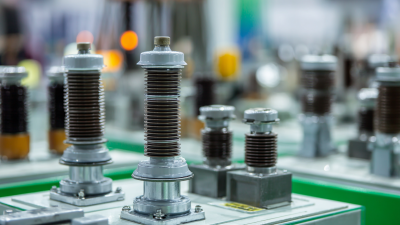

Standoff insulators are gaining traction across various industries due to their innovative applications and the trend towards more sustainable choices in materials. According to the latest market report on high voltage electric insulators, the sector is expected to witness substantial growth, driven by the increasing demand in energy transmission and distribution systems. By 2034, the high voltage electric insulators market is forecast to expand significantly, highlighting the critical role of these components in maintaining system reliability while enhancing safety.

One notable trend is the application of polymer technologies in standoff insulators, particularly within the aerospace sector. The shift towards lightweight, durable plastics not only improves the efficiency of aircraft and spacecraft but also contributes to lower overall manufacturing costs. With the growing adoption of these materials, standoff insulators are becoming essential in ensuring optimal performance in various environments. This evolution demonstrates how industries are embracing advanced composites to meet the challenges of modern engineering while promoting innovation and sustainability.

| Application Area | Industry | Innovative Feature | Benefits |

|---|---|---|---|

| Overhead Transmission Lines | Utilities | Heightened Structural Integrity | Increased durability and reduced maintenance costs |

| Wind Turbines | Renewable Energy | Lightweight and Corrosion-Resistant | Longer lifespan and improved energy efficiency |

| Railway Systems | Transportation | Enhanced Insulation Properties | Increased safety and reliability of signaling systems |

| Telecommunication Towers | Telecommunications | Advanced UV Resistance | Reduced replacement frequency and maintenance efforts |

| Smart Grids | Energy Management | Integrated Sensor Technology | Real-time monitoring and improved system efficiency |

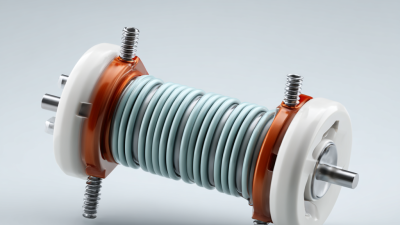

Standoff insulators play a crucial role in electrical transmission lines, offering both mechanical support and electrical insulation. Comparative analysis of different material types reveals a range of benefits that can enhance the performance and reliability of these essential components. Among the material options, porcelain standoff insulators are renowned for their durability and resistance to weather-induced creep, boasting a lifespan that can extend beyond 50 years under optimal conditions. According to the IEEE 48 standards, porcelain insulators maintain their insulating properties even in extreme environmental conditions, making them ideal for regions prone to harsh weather patterns.

In contrast, composite insulators, often made from polymer materials, have gained popularity in recent years due to their lightweight and high mechanical strength. According to a report by the Electric Power Research Institute (EPRI), composite insulators reduce the risk of breakage and are up to 30% lighter than their porcelain counterparts, leading to cost savings in installation and maintenance. Furthermore, composite materials exhibit excellent hydrophobic properties, which enhances their performance in contaminated environments. These unique characteristics make composite standoff insulators increasingly favored for modern electrical infrastructure, where agility and resilience are paramount.

Standoff insulators play a crucial role in the renewable energy sector, particularly in wind and solar energy projects. These insulators help maintain electrical isolation while supporting various components in harsh environmental conditions. For instance, in a recent wind farm project, standoff insulators were utilized to enhance the reliability and efficiency of the power transmission system. By keeping electrical lines safely distanced from the turbine structures, they minimized maintenance needs and reduced the risk of short circuits, thereby optimizing the energy output.

Standoff insulators play a crucial role in the renewable energy sector, particularly in wind and solar energy projects. These insulators help maintain electrical isolation while supporting various components in harsh environmental conditions. For instance, in a recent wind farm project, standoff insulators were utilized to enhance the reliability and efficiency of the power transmission system. By keeping electrical lines safely distanced from the turbine structures, they minimized maintenance needs and reduced the risk of short circuits, thereby optimizing the energy output.

In solar energy installations, standoff insulators serve to elevate solar panels off the ground, preventing moisture accumulation and promoting effective airflow. A notable case study involved a large-scale solar farm that incorporated standoff insulators to maintain panel integrity and extend the lifespan of the system. These insulators enabled the panels to withstand extreme temperatures and heavy rain without compromising the electrical connections. As renewable energy continues to expand, the innovative application of standoff insulators will remain central to enhancing the performance and reliability of energy systems.

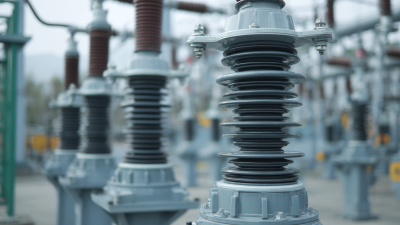

Standoff insulators play a crucial role in modern electrical engineering by enhancing efficiency and reliability in various applications. Their innovative designs not only support high-voltage equipment but also significantly reduce energy loss. These insulators maintain optimal distance between conductive parts and the grounded structure, which minimizes the risk of short circuits and electrical arcing.

Tips for maximizing efficiency with standoff insulators include selecting the appropriate material based on environmental conditions, such as temperature and humidity. Additionally, regularly inspect these insulators for signs of wear or damage, which can compromise their effectiveness. Utilizing standoff insulators with integrated monitoring systems can further enhance operational safety and reduce unexpected downtime.

Furthermore, consider adopting advanced designs that incorporate features like hydrophobic surfaces to repel moisture, thereby improving performance in adverse weather conditions. Implementing these innovative insulator designs not only boosts overall system reliability but also promotes sustainable practices by reducing energy waste and optimizing resource utilization.

Standoff insulators have emerged as a cost-effective alternative to traditional insulation solutions, particularly in the context of building energy efficiency. These innovative components not only provide thermal insulation but also allow for the uninterrupted application of rigid foam, enhancing the performance of continuous insulation systems. This is especially significant in areas with evolving building codes, where the demand for improved U-values has become a crucial factor in construction.

Recent advancements highlight the integration of inorganic textile-based composites with thermal insulation, showcasing their potential to meet both seismic and energy performance requirements. By adopting standoff insulators, construction professionals can streamline their insulation processes while adhering to strict regulations, ultimately reducing long-term operational costs.

This unique application not only fosters enhanced building sustainability but also creates opportunities for more innovative design solutions in the architectural landscape.