Leave Your Message

In the realm of electrical systems, the importance of selecting the appropriate Stand Off Insulator cannot be overstated. According to a report by the International Electrotechnical Commission (IEC), improper insulator choice can lead to a staggering 30% increase in system failures, resulting in costly downtimes and safety hazards. Stand Off Insulators play a crucial role in maintaining electrical integrity, supporting conductors, and providing spacing from grounded structures to mitigate electrical arcing and short circuits. As the demand for reliable and efficient electrical infrastructure grows, understanding the distinct types and applications of Stand Off Insulators becomes imperative. Whether in high-voltage transmission lines or intricate distribution networks, choosing the right insulator based on material, environmental conditions, and voltage ratings is essential for enhancing performance and longevity of the electrical system. This guide aims to provide comprehensive insights and tips to help you navigate the complexities of selecting the ideal Stand Off Insulator for your unique electrical needs.

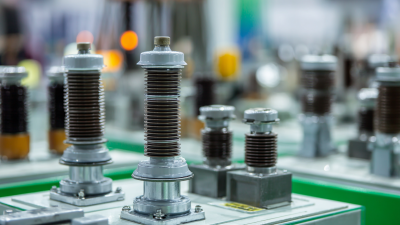

Stand off insulators play a crucial role in electrical systems by providing the necessary separation between conductors and supporting structures. Their primary function is to insulate electrical components from the ground and other conductive surfaces, reducing the risk of short circuits and enhancing overall system reliability. In high-voltage applications, these insulators are vital as they help manage electrical stress and ensure safe operation. By maintaining a safe distance between energized parts, stand off insulators protect both equipment and personnel from potential electrical hazards.

Understanding the material composition and design of stand off insulators is essential for selecting the right product for specific electrical needs. Common materials such as porcelain, glass, and polymer each have unique properties that influence their performance in different environments. For instance, while porcelain offers exceptional strength and durability, polymers can provide greater flexibility and resistance to environmental factors like UV radiation and moisture. Therefore, choosing the appropriate stand off insulator not only ensures compliance with safety standards but also optimizes the performance and longevity of electrical systems.

When selecting the right stand off insulator for your electrical application, it's essential to understand the different types available and their specific uses. Common options include porcelain, polymer, and glass insulators. Porcelain insulators are known for their strength and durability, making them ideal for high-voltage applications and outdoor use. They can withstand harsh weather conditions and have excellent insulating properties, which helps in preventing electrical leakage.

On the other hand, polymer insulators offer a lightweight alternative with superior resistance to vandalism and environmental stressors. Their flexibility allows them to perform well in areas with high wind loads or seismic activity, while also reducing the risk of breakage. Glass insulators, though less common today, are valued for their transparency and high dielectric strength, making them effective for both aesthetic and functional purposes. When choosing insulators, consider factors like voltage levels, environmental conditions, and installation requirements to ensure optimal performance in your specific application.

When selecting the right stand-off insulators for your electrical needs, several key factors must be taken into account to ensure optimal performance and safety. One of the most crucial aspects is the voltage classification of the insulator, which should match or exceed the operational voltage of the system. According to a report from the Institute of Electrical and Electronics Engineers (IEEE), mismatching the voltage rating can lead to electrical failures and increased maintenance costs, underscoring the importance of proper selection.

Material composition is also vital in the decision-making process. Stand-off insulators made from advanced materials like polymer composites offer superior resistance to environmental stressors such as UV exposure and moisture, significantly extending their lifespan. A study by the Electric Power Research Institute (EPRI) highlights that polymer insulators can last up to 40% longer than traditional ceramic options in harsh conditions. Furthermore, the electrical properties of these materials provide better performance in terms of surface leakage resistance, further enhancing reliability.

Lastly, installation and mounting options cannot be overlooked. The versatility of stand-off insulators allows for various mounting configurations, which can affect installation ease and effectiveness. EPRI findings suggest that improper mounting can lead to mechanical failures, thus emphasizing the need for compatibility with existing infrastructure. By prioritizing these key factors—voltage rating, material choice, and installation method—you can make informed decisions that cater to your electrical system’s specific requirements.

When it comes to installing stand off insulators, proper technique is crucial for ensuring optimal performance. Start by selecting the right location for installation. Choose a site that offers a stable base and ample clearance from other structures to prevent any potential interference. Make sure to follow the manufacturer's guidelines regarding the minimum distance required from power lines and other electrical components to maintain safety standards.

Next, pay attention to the mounting process. Ensure that the insulator is securely fastened to prevent any movement that may lead to wear or damage over time. Use high-quality hardware to enhance the durability of the installation. It's also essential to inspect the area for sharp edges or potential hazards that could compromise the integrity of the insulator. After installation, conduct routine maintenance checks to identify any signs of stress or deterioration early on, which will help prolong the lifespan of your electrical system.

When selecting stand off insulators for your electrical projects, it's crucial to avoid common mistakes that can lead to safety hazards or performance issues. One prevalent error is underestimating the voltage rating required for the application. Many users impulsively choose insulators based on appearance or cost, neglecting to verify if they can handle the operational voltage. Always consider the maximum voltage that will be encountered in your system to ensure safe and reliable performance.

Another mistake is overlooking environmental factors that affect the insulator's durability. It's essential to assess the environmental conditions, such as UV exposure, temperature fluctuations, and moisture levels, before making a choice. For instance, insulators made from materials with poor weather resistance may degrade over time, leading to potential failures. Ensure you select insulators that are specifically designed for the environments they will be exposed to, thereby enhancing both the longevity and safety of your electrical setup.