Leave Your Message

In today's world, heat resistant insulators play a vital role in various industries. They protect against extreme temperatures and help maintain safety. These materials are crucial in applications like construction, manufacturing, and power generation.

Choosing the right heat resistant insulator can be challenging. Many options exist, each with unique properties. Understanding these variations is essential for making informed decisions. A poor choice may lead to failures or safety issues in critical settings.

This guide explores the top five heat resistant insulators you need to know. From fiberglass to ceramic, each material offers distinct benefits. We will delve into their properties, applications, and potential drawbacks. This knowledge will empower you to choose wisely and enhance efficiency in your projects.

In high-temperature environments, heat resistance is critical for safety and efficiency. Insulators play a vital role in protecting materials and structures from extreme heat. According to the Thermal Insulation Association, properly selected insulation can reduce energy loss by up to 90% in industrial applications. This not only saves energy but also minimizes operational costs.

Different materials offer various levels of heat resistance. For instance, ceramic insulators can withstand temperatures exceeding 1,600°C. However, they often crack under stress. Meanwhile, mineral wool provides decent insulation but may not perform well in moist conditions. In a recent study by the Journal of Engineering, they highlighted that up to 30% of thermal energy could escape due to subpar insulation. Inadequate choices can lead to failures and increased expenses.

The selection process can be complex. Factors such as thermal conductivity, weight, and chemical resistance must be considered. Thus, industries may overlook these variables, resulting in costly errors. Achieving optimal insulation requires an understanding of specific needs and constraints. Balancing cost and performance is often a tricky path to navigate.

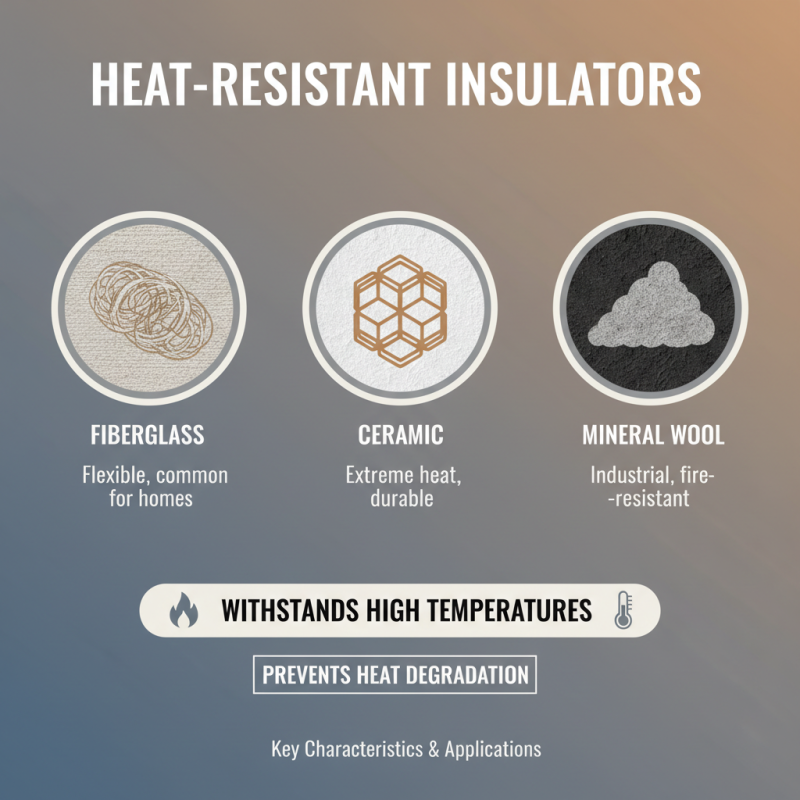

When it comes to heat-resistant insulation, materials make all the difference. Some common options include fiberglass, mineral wool, and ceramic fiber. These materials are chosen for their exceptional thermal properties. For example, fiberglass can withstand temperatures up to 540°C (1000°F), making it a favored choice for many applications.

Mineral wool is another popular option. It not only offers a high melting point but also provides excellent acoustical properties. According to the U.S. Department of Energy, mineral wool typically handles temperatures of 1000°C (1832°F). Such features make it ideal for industrial settings where heat management is critical.

Ceramic fiber is known for its lightweight and flexibility. This material can endure extreme temperatures exceeding 1260°C (2300°F). Interestingly, while ceramic fiber is effective, it requires careful handling due to its fragility. This underscores the need for thorough safety protocols. Each of these materials has strengths and weaknesses that warrant careful consideration before making a choice.

When considering heat resistant insulators, understanding their characteristics is vital. These materials must withstand high temperatures without degrading. Commonly used insulators include ceramic, fiberglass, and mineral wool. Each has unique properties suited for specific applications. For example, ceramic insulators excel in high-temperature environments. They are durable and can handle extreme conditions.

In industrial settings, fiberglass is popular due to its lightweight and flexibility. It resists moisture and is easy to install. However, it can be prone to damage if mishandled. Mineral wool offers excellent sound and thermal insulation but may require protective gear during installation.

Choosing the right insulator involves balancing performance and safety. The application environment matters. Insulation quality can affect energy efficiency greatly. Sometimes, the most suitable option may not be the most obvious choice. It's essential to evaluate all aspects before making a decision. Take time to review specifications carefully.

When analyzing insulator performance at elevated temperatures, several key materials stand out. Silicon nitride, for example, can maintain integrity up to 1,600°C. Its thermal stability makes it suitable for extreme environments. However, it can be brittle, raising questions about durability in dynamic conditions.

Another contender is alumina. This ceramic insulator performs well to about 1,200°C. It offers excellent resistance to thermal shock. Yet, its processing can be complex, often leading to variability in quality. A recent study indicated that approximately 12% of samples fail to meet rigorous thermal performance standards due to these inconsistencies.

Mica is a natural insulator that withstands high temperatures, reaching up to 500°C. It's lightweight and flexible. However, its performance can degrade over time, especially in humid conditions. An industry report showed that nearly 15% of mica insulators show reduced efficacy after extended exposure to moisture. This highlights the importance of continuous monitoring and testing in the field to ensure reliability.

The future of heat resistant insulators is evolving rapidly. New materials are emerging that promise better performance. Scientists are experimenting with aerogels and advanced ceramics. These materials are lightweight and offer superior thermal resistance. They can withstand extreme temperatures without degrading.

Nanotechnology is another exciting trend. It enhances insulator properties at a molecular level. This can lead to thinner, more efficient products. However, the cost of production remains a concern. The industry needs to find a balance between performance and affordability. Additionally, some new materials may lack long-term reliability. Their behavior under stress is not fully understood yet.

Sustainability is also a key focus. Eco-friendly materials are gaining popularity. Research is underway to develop bio-based insulators. These options could reduce environmental impact. Yet, it's crucial to ensure they perform well under heat. The path forward is filled with potential challenges and opportunities.

| Insulator Type | Temperature Resistance (°C) | Thermal Conductivity (W/m·K) | Applications | Advantages |

|---|---|---|---|---|

| Ceramic Fiber | 1260 | 0.15 | Industrial furnaces, boilers | Lightweight, high insulation |

| Mineral Wool | 1000 | 0.04 - 0.07 | Building insulation, HVAC | Fire resistant, sound absorption |

| Calcium Silicate | 1100 | 0.07 - 0.12 | Pipelines, industrial equipment | Excellent thermal stability |

| Fiberglass | 540 | 0.04 - 0.07 | Walls, roofs, pipelines | Cost effective, versatile |

| Polyimide Foam | 300 | 0.025 - 0.05 | Aerospace, automotive | Lightweight, excellent performance |