Leave Your Message

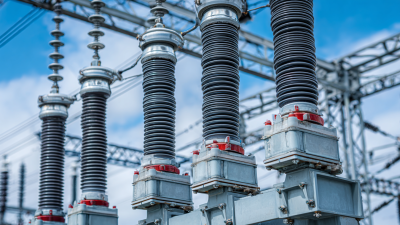

In the ever-evolving field of electrical engineering, understanding the various types of electrical conductor insulator materials is crucial for ensuring system efficiency and safety. According to the International Electrotechnical Commission (IEC), the global market for electrical insulators is projected to reach $19.65 billion by 2024, driven by the increasing demand for renewable energy solutions and smart grid technologies. Electrical conductor insulators play a vital role in preventing short circuits and ensuring optimal performance in various applications, from power generation to telecommunications.

Numerous studies highlight the significance of selecting the appropriate electrical conductor insulator type, as it not only affects the conductivity and dielectric strength of electrical systems but also influences the overall durability and lifespan of electrical components. For example, the Global Insulation Market Report indicates that high-performance insulators can improve energy efficiency by up to 30%, underscoring the importance of material selection for operational efficacy. As we delve into the top 10 electrical conductor insulator types, this guide will elucidate their characteristics, applications, and advantages, providing valuable insights for engineers, technicians, and industry professionals alike.

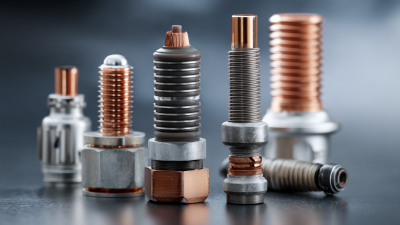

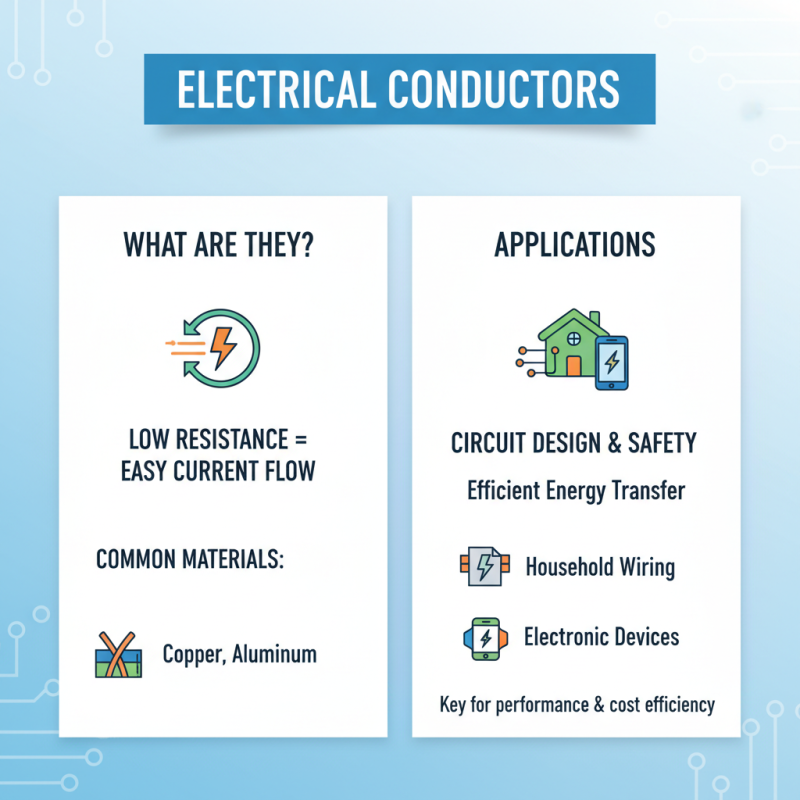

Understanding the properties of electrical conductors is crucial for anyone engaged in electrical engineering or related fields. Conductors are materials that allow the flow of electric current, and they exhibit varying degrees of conductivity based on their atomic structure. Commonly used conductors include metals such as copper and aluminum, which have free electrons that facilitate current flow. The conductivity of a material is influenced by factors such as temperature, impurities, and the physical state of the conductor. For instance, increasing temperature typically increases resistivity, thus reducing conductivity.

On the other hand, insulators are materials that resist the flow of electric current. They possess tightly bound electrons that do not move freely, making them essential for preventing unwanted current loss and safeguarding circuits from shorting. Common insulator materials include rubber, glass, and certain plastics. The effectiveness of an insulator is measured by its dielectric strength, which indicates how much voltage it can withstand before becoming conductive. Selecting the right combination of conductors and insulators is vital for ensuring efficient electrical systems, minimizing energy loss, and maintaining safety standards. Understanding these properties helps engineers design better circuits and choose materials that meet specific application requirements.

Insulating materials play a crucial role in the effectiveness and safety of electrical systems. Common insulation types, such as PVC, rubber, and polyethylene, are instrumental in preventing electrical leakage and shorts. According to a report by the International Electrotechnical Commission (IEC), nearly 30% of electrical failures in installations can be traced back to inadequate insulation. PVC, for example, is favored for its durability and cost-effectiveness, particularly in residential wiring, where it helps mitigate issues related to moisture and temperature fluctuations.

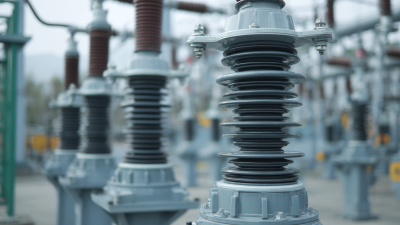

Another significant insulating material is rubber, which excels in high-voltage applications due to its excellent dielectric properties. Research from the IEEE indicates that rubber insulation can withstand voltages up to 20 kV, making it ideal for industrial equipment and power transmission lines. Polyethylene, often used in high-frequency applications, provides minimal signal loss, which is vital in telecommunications. Furthermore, advanced materials like cross-linked polyethylene (XLPE) offer enhanced thermal properties and chemical resistance, facilitating their use in diverse environments, from underground cables to power plants. Understanding these insulating materials and their respective functions is essential for ensuring reliable and safe electrical infrastructures.

In the realm of electrical engineering, understanding the distinct properties and applications of conductors and insulators is vital for effective circuit design and safety. Conductors, such as copper and aluminum, are materials that allow the easy flow of electrical current due to their low resistance. This property makes them ideal for connecting components in electrical circuits, enabling efficient energy transfer. Applications range from household wiring to sophisticated electronic devices, where the choice of conductor can significantly impact performance and cost efficiency.

On the other hand, insulators, including materials like rubber and glass, serve the critical function of preventing current from flowing where it is not intended. They protect users from electric shocks and contain electricity within designated pathways, thereby enhancing safety in electrical systems. In practical applications, insulators are used in power lines, capacitors, and as coatings for wires, ensuring that energy is delivered without risking leakage or interference. The effectiveness of both conductors and insulators is influenced by factors such as temperature, environment, and mechanical strength, making their selection crucial in designing safe and reliable electrical systems. Understanding the comparative advantages of each type is essential for optimizing performance in various electrical applications.

When dealing with electrical conductors and insulators, safety standards and regulations are paramount to ensure the protection of both individuals and equipment. These standards are developed by various organizations that focus on establishing guidelines for the safe installation, operation, and maintenance of electrical systems. They cover factors such as the material properties of conductors and insulators, their electrical ratings, thermal performance, and resistance to environmental conditions. Compliance with these standards is essential, as they help to mitigate risks such as electrical shocks, short circuits, and potential fires.

Moreover, regulations often vary by region and can be influenced by local building codes, safety practices, and industry-specific requirements. It is crucial for professionals in the electrical field to stay updated on the latest standards from organizations such as the National Electrical Code (NEC) or the International Electrotechnical Commission (IEC). These regulations not only dictate the types of materials that can be used but also specify installation practices to ensure that electrical systems operate safely and efficiently. Keeping abreast of these standards ensures that both residential and industrial applications of electrical conductors and insulators adhere to best practices while maintaining safety for all stakeholders involved.

Emerging innovations in electrical conductors and insulating technologies are transforming the landscape of the electrical engineering field. With the ever-increasing demand for energy efficiency and improved performance, researchers and engineers are exploring new materials and methods that enhance the conductivity and insulation properties of electrical components. Advances in nanotechnology have paved the way for the creation of superconductive materials that significantly minimize resistance and energy loss, making them ideal for high-performance applications in power grids and transportation systems.

Additionally, the development of biodegradable insulating materials is gaining traction as sustainability becomes a critical concern in technology. These eco-friendly alternatives not only reduce environmental impact but also offer comparable performance to traditional synthetic insulators. Smart materials with self-monitoring capabilities are also emerging, allowing systems to detect and respond to changes in environmental conditions or stressors, thereby enhancing reliability and longevity. This confluence of innovation positions the electrical sector for a future that is not only more efficient but also more sustainable and resilient in the face of evolving technological demands.

| Conductor Type | Insulator Type | Application | Emerging Innovations |

|---|---|---|---|

| Copper | Polyethylene (PE) | Residential Wiring | Improved Thermal Resistance |

| Aluminum | Cross-Linked Polyethylene (XLPE) | Power Distribution | Enhanced UV Resistance |

| Gold | Silicone | High-End Electronics | Nano-Coating Technology |

| Silver | Teflon | Aerospace Applications | Self-Healing Insulators |

| Carbon | Epoxy Resins | Industrial Machinery | Biodegradable Insulation |

| Nickel | Polyvinyl Chloride (PVC) | Automotive Wiring | Low Smoke Zero Halogen (LSZH) Compositions |

| Brass | Fiberglass | Communication Cables | Flexible Insulation Materials |

| Titanium | Ceramic | High Voltage Applications | High-Temperature Conductors |

| Superconductors | Aerogel | Magnetic Levitation | Cryogenic Insulation Techniques |