Leave Your Message

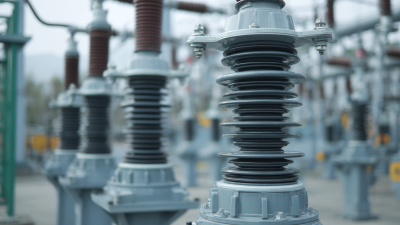

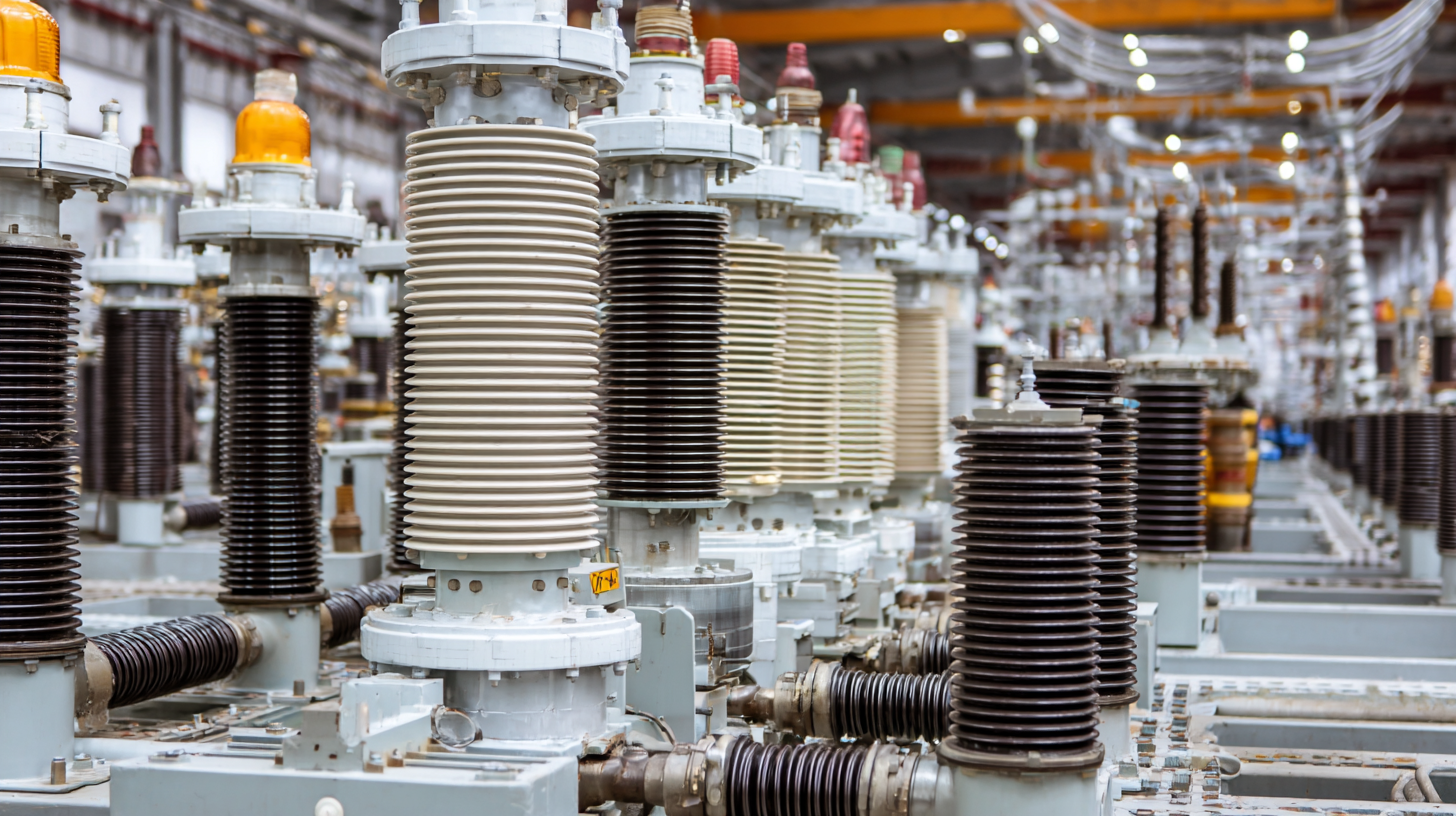

In the evolving landscape of the electrical insulator market, composite insulators are gaining significant traction due to their superior performance characteristics and durability. According to a recent report by MarketsandMarkets, the global composite insulator market is projected to reach USD 9.3 billion by 2025, growing at a CAGR of 5.4% from 2020. This growth is driven by the increasing demand for renewable energy sources and the need for upgraded aging infrastructure. Understanding the key players in this field is essential for stakeholders looking to procure high-quality materials. Therefore, identifying the top Composite Insulator Suppliers becomes crucial for ensuring reliability and efficiency in electrical transmission and distribution systems. This article delves into the five leading suppliers of composite insulators in 2023, showcasing their contributions to enhancing and performance.

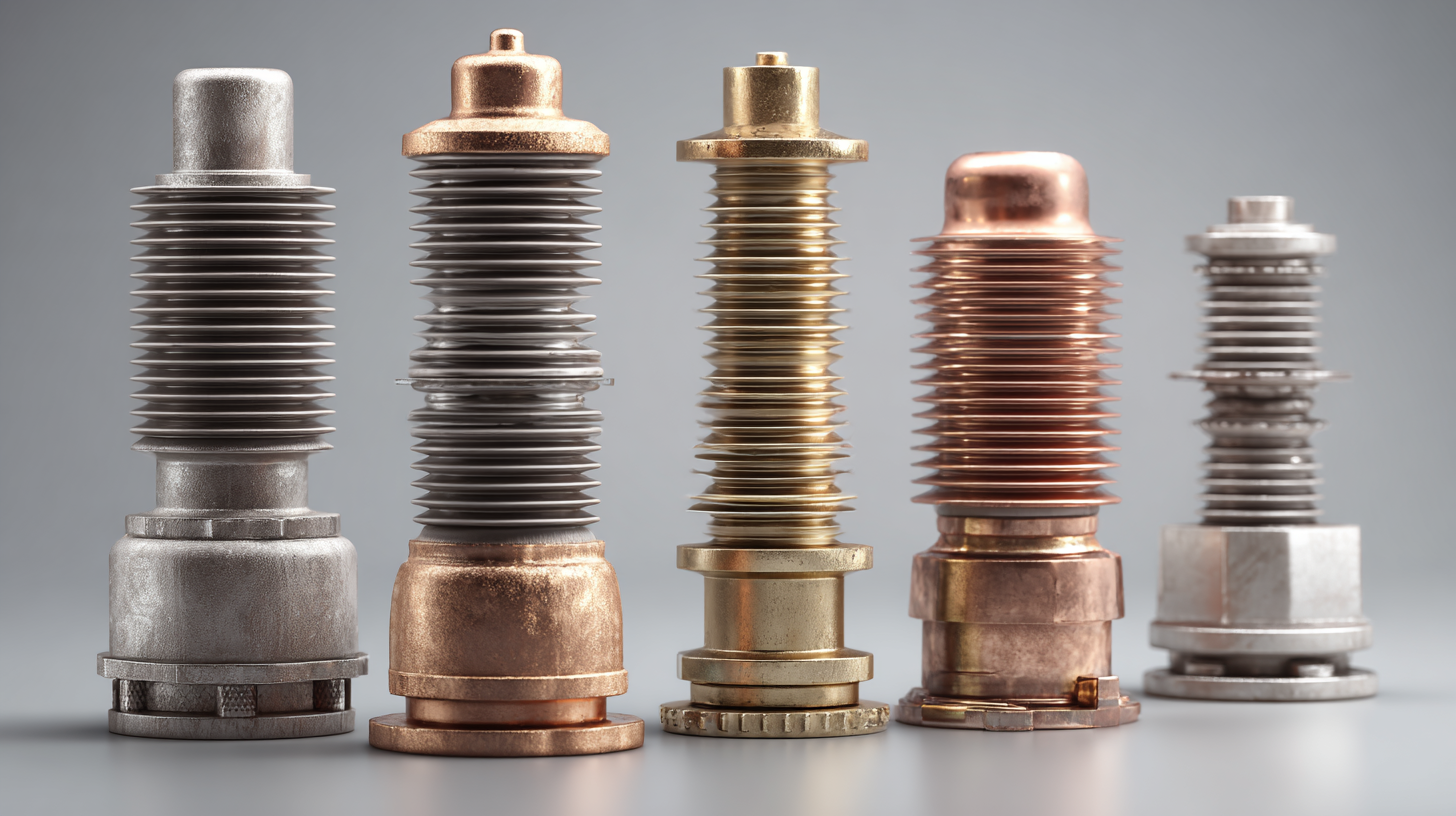

When selecting composite insulator suppliers in 2023, it’s crucial to consider several key factors to ensure quality and reliability. First and foremost, evaluate the supplier’s experience and reputation in the industry. A well-established supplier with a proven track record is more likely to deliver high-quality products and responsive customer service. Moreover, look for manufacturers that adhere to international standards and certifications, as this demonstrates commitment to safety and performance.

Another important factor is the supplier's ability to provide technical support and customization options. This is especially vital for projects that require specific insulation properties or configurations. Assess whether they offer consultation services and are willing to adapt their products to meet your unique needs.

**Tips:** Always ask for client references and case studies to gain insight into the supplier's capabilities. Additionally, consider the geographical location of the supplier; local suppliers can often offer quicker turnaround times and more accessible support. Lastly, inquire about their warranty and after-sales service, as these will play a crucial role in your long-term satisfaction with the product.

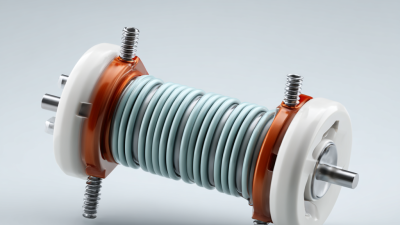

When selecting a composite insulator provider, there are several key features to consider that can greatly influence the performance and reliability of the products. First and foremost, look for manufacturers with a strong reputation for quality assurance. This often translates to rigorous testing standards and certifications that demonstrate the durability and performance of their insulators under various environmental conditions. You should also assess whether the supplier utilizes advanced materials and innovative designs that can enhance resistivity and mechanical strength, as these factors are crucial for ensuring long-term functionality in demanding applications.

Another important feature is the provider's customer service and support system. A reliable supplier should offer comprehensive technical support, helping you navigate product selection, installation, and maintenance processes. Responsiveness to inquiries and a willingness to collaborate on custom solutions can also be indicative of strong customer relationships, which is vital for addressing specific needs and challenges. Lastly, consider the availability of a broad product range, which can provide you with flexible options tailored to your specific requirements, ensuring that you are not limited to a one-size-fits-all solution.

In 2023, the landscape of composite insulator suppliers is marked by significant innovations aimed at enhancing performance and sustainability. Leading companies in the sector are now focusing on advanced materials that offer superior electrical performance and reduced environmental impact. For instance, a recent market analysis by Technavio highlights that the global composite insulators market is projected to grow at a CAGR of over 5% from 2022 to 2026, underscoring the increasing demand for durable and lightweight insulating solutions.

Moreover, suppliers are implementing smart technologies within their products. This includes the integration of sensors that monitor the health of insulators, providing real-time data to prevent failures and reduce maintenance costs. According to a report by MarketsandMarkets, the smart insulator market is expected to reach $2.5 billion by 2025, driven by the rising emphasis on grid modernization and automation.

Tips: When selecting a composite insulator supplier, consider their commitment to innovation and sustainability. Investigate their product offerings and ask about integrated technology features that can enhance the longevity and reliability of their products. Additionally, look for suppliers who provide comprehensive support and training on installation and maintenance, ensuring optimal performance of your insulation systems.

When selecting a composite insulator supplier, reputation and customer feedback are critical factors to consider. According to a report by MarketsandMarkets, the composite insulator market is expected to grow from $1.2 billion in 2020 to $2.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 12.5%. This rapid growth highlights the increasing reliance on composite insulators in various applications, making the reputation of suppliers more vital than ever.

Customer feedback often serves as an essential indicator of a supplier's reliability and product quality. Recent surveys indicate that 78% of customers prioritize suppliers with proven track records and positive testimonials. Furthermore, industry reports suggest that suppliers with strong customer service and after-sales support enjoy higher customer retention rates, with some reaching 85%. Thus, when evaluating potential composite insulator suppliers in 2023, it is crucial to examine their reputation within the industry, as well as the experiences shared by other customers, to ensure the selection of a supplier that aligns with reliability and quality expectations.

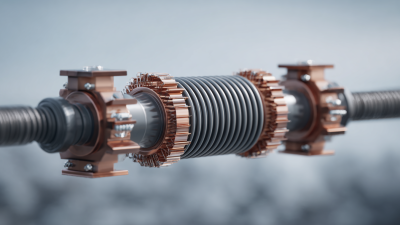

In 2023, the demand for composite insulators has surged, driven by the need for enhanced durability and performance in electrical transmission systems. A comparative analysis of the top suppliers reveals a landscape characterized by innovation, product diversity, and global outreach. Among the leading contenders, **Supplier A** stands out for its cutting-edge manufacturing techniques and rigorous quality control processes. Their insulators offer a blend of lightweight design and exceptional resistance to environmental stresses, making them ideal for harsh conditions.

Another key player is **Supplier B**, known for their extensive range of composite insulators tailored for different applications. Their commitment to research and development has resulted in products that incorporate advanced materials, which significantly prolong the service life of insulators. Furthermore, **Supplier C** has made significant strides in sustainability, leveraging eco-friendly materials while maintaining high performance standards. Each of these suppliers not only provides top-tier products but also emphasizes customer support and robust service networks, ensuring reliability in the supply chain for ongoing projects. These attributes are critical in a market where the reliability of electrical infrastructure is paramount.