Leave Your Message

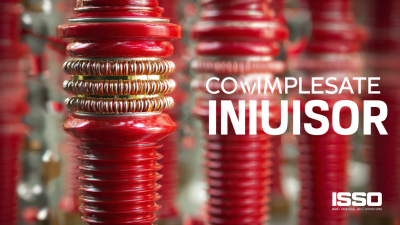

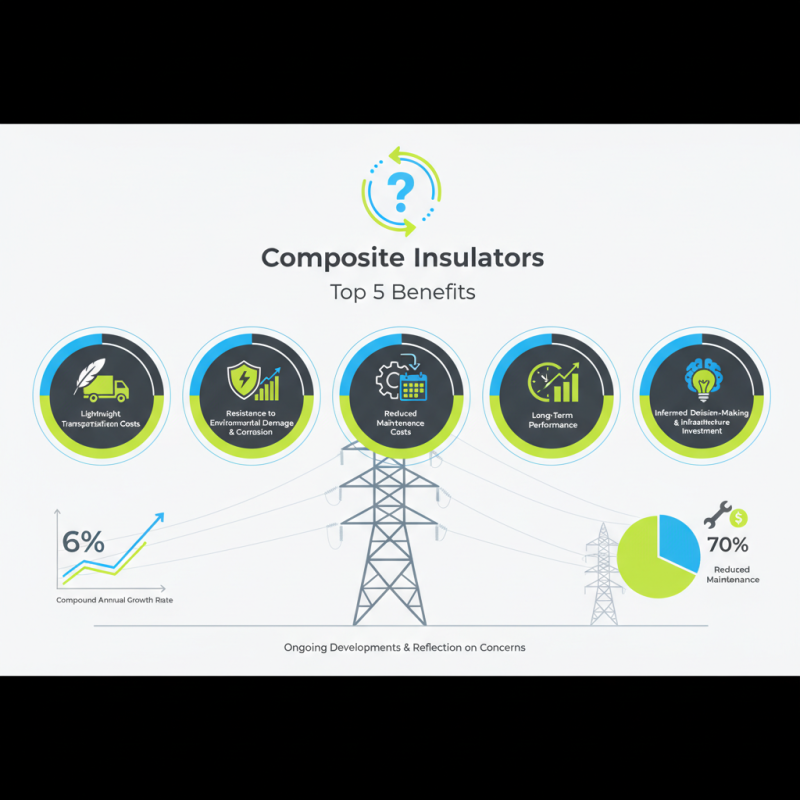

Composite insulators have gained significant traction in the electrical industry. A report by TechNavio predicts a compound annual growth rate of 6% for the composite insulator market until 2026. These materials provide multiple advantages over traditional insulators.

One key benefit is their lightweight nature. This feature reduces transportation and installation costs. Furthermore, composite insulators are resistant to environmental damage and corrosion, making them ideal for harsh conditions. A survey indicated that over 70% of utility companies report reduced maintenance costs due to their durability.

However, not all aspects are perfect. Some industry professionals highlight concerns about the long-term performance of composite materials. Reflection on these issues is crucial for ongoing developments. Ultimately, understanding composite insulators' benefits can foster better decision-making in infrastructure investments.

Composite insulators offer significant advantages in electrical applications. They can withstand harsh weather conditions, which is crucial for outdoor installations. Their lightweight nature makes them easier to handle and install, reducing labor costs. Additionally, composite materials resist the accumulation of dirt and pollutants, which can improve performance over time. This means maintenance can be less frequent, although it’s important not to overlook it entirely.

Another benefit is their superior electrical insulation properties. They can handle high voltages effectively without breaking down. While they are durable, it's essential to monitor for signs of wear. Some users may find them less familiar than traditional materials. This could lead to hesitation in adoption. Understanding their long-term performance is key. Despite these challenges, composite insulators present a reliable solution for modern electrical infrastructure.

Composite insulators are gaining popularity for their enhanced durability. They are designed to withstand harsh environmental conditions. This makes them ideal for use in various electrical applications. Unlike traditional materials, composites resist cracking under stress. They are also less likely to deteriorate due to extreme temperatures.

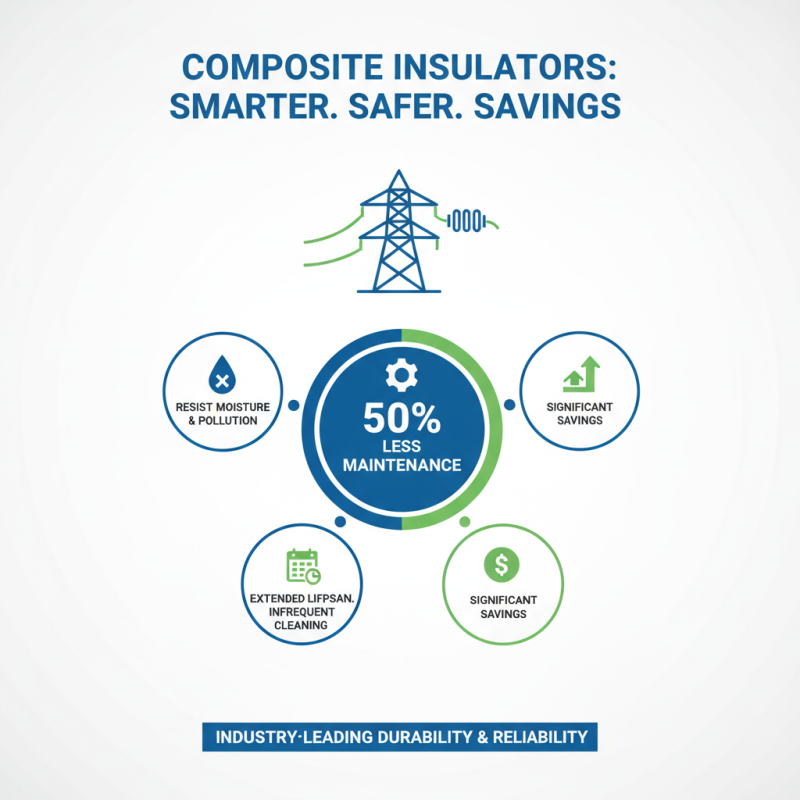

These insulators offer substantial resistance to moisture and pollution. This is critical in areas with high levels of industrial emissions. Additionally, they reduce the risk of flashover, which can be a significant safety concern. The lightweight nature of composite materials also allows for easier installation. However, some may still question their long-term performance.

Environmental challenges can be unpredictable. Composite insulators, while strong, are not immune to wear. Regular inspection is essential to ensure they remain effective. Maintenance should not be overlooked. Sometimes, it’s easy to assume that durability equates to a lack of care. In reality, reflection on performance can lead to improvements in design and usage.

When it comes to composite insulators, weight efficiency is a crucial advantage. The lightweight design significantly reduces the stress on supporting structures, enhancing overall system performance. For installations in remote areas, this can make a big difference. Workers can transport materials easily. Heavy equipment is less required. This means lower costs and faster installation times.

A lighter insulator also results in less mechanical stress. This can lead to fewer failures over time. However, it’s important to carefully consider the material composition. Some lightweight options might lack the same durability as heavier counterparts. Continuous monitoring is essential to ensure long-term effectiveness. The balance between weight and performance is delicate.

Utilizing lightweight designs may appear ideal, but challenges can arise. Installers must stay vigilant during harsh weather. Winds and storms can affect lighter structures more dramatically. There is a growing need for innovation. Better designs should focus on maintaining strength while ensuring weight efficiency. As we advance, the pursuit of finding the perfect blend continues.

This chart illustrates the top benefits of composite insulators, highlighting their weight efficiency and other key attributes that enhance their performance in various applications. Each benefit is rated on a scale of 1 to 10 based on industry feedback.

Composite insulators provide outstanding electrical performance. Compared to traditional materials, such as porcelain or glass, they bring unique advantages. They can withstand extreme weather conditions without deteriorating. This capability results in lower maintenance costs and fewer outages.

When selecting insulators, consider the environment they will be used in. Weather extremes can impact durability. Composite materials are less likely to crack under harsh conditions, which is a significant concern with glass.

Tips: Always check the insulation resistance of any material. Conduct regular checks to ensure everything is working correctly. A minor issue today can become a larger problem tomorrow. Remember, durability is important, but so is performance.

Composite insulators are increasingly more popular in various applications. One key benefit is their reduced maintenance requirements. These insulators can last much longer than traditional materials. For instance, they resist moisture and pollution, leading to lower cleaning frequencies. Industry reports indicate that maintenance can be reduced by up to 50% with composite designs. This translates into significant labor savings for utilities and companies.

Long-term cost savings are another critical factor. Composite insulators typically have a longer lifespan, often exceeding 30 years. In contrast, glass or ceramic insulators may need replacement every 20 years. According to studies from industry experts, the initial investment in composite insulators can be offset by avoided replacement costs. This could lead to savings of around 20% over a 30-year period.

Of course, challenges do exist. Some users report needing initial training to understand the unique properties of composite materials. Also, performance can be influenced by environmental factors like UV exposure. These variables should prompt careful consideration. Evaluating both the pros and cons is essential for optimal investment decisions in the long run.

Composite insulators have emerged as a superior choice in electrical applications due to their numerous benefits. Firstly, they offer enhanced durability against various environmental challenges, making them reliable for long-term use in diverse weather conditions. The lightweight design of composite insulators provides significant weight efficiency, reducing the load on support structures and simplifying installation processes.

In addition to their physical advantages, composite insulators demonstrate superior electrical performance compared to traditional materials, ensuring better transmission and distribution of electric power. They also contribute to reduced maintenance requirements, leading to long-term cost savings for power systems. Moreover, the eco-friendly attributes of composite insulators further underscore their value in modern power infrastructure, aligning with sustainability goals while maintaining high operational efficiency. Overall, the adoption of composite insulators represents a forward-thinking approach to enhancing the reliability and performance of electrical networks.