Leave Your Message

In the dynamic world of electrical engineering, busbar insulators play an essential role. Experts agree on their importance. "Quality busbar insulators are crucial for reliable energy distribution," says Dr. Emily Carter, a leading specialist in the field. Her insights highlight the value of these components in our electrical systems.

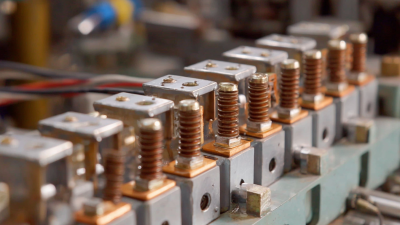

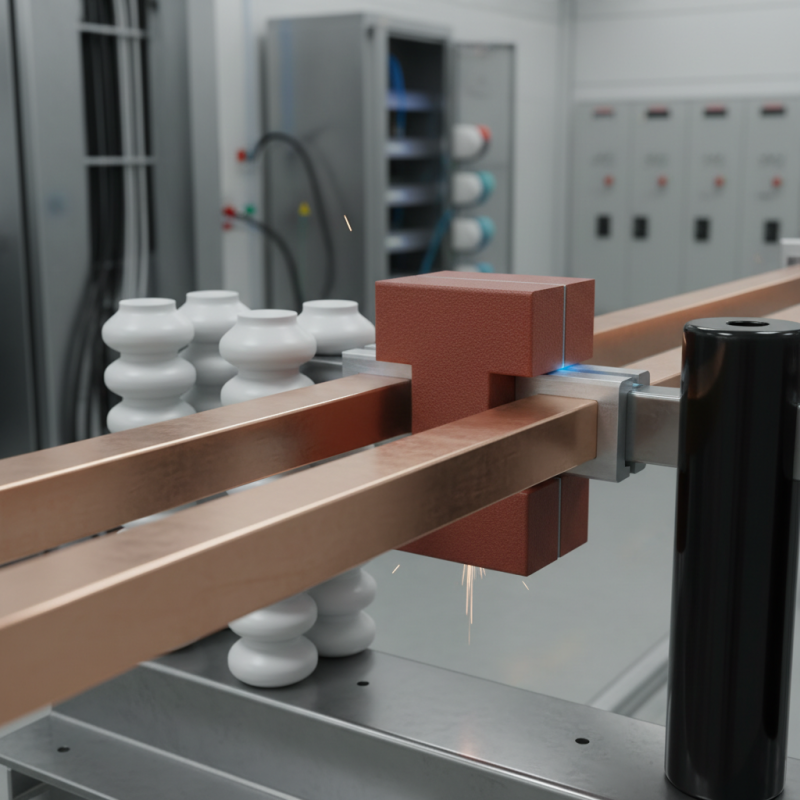

Busbar insulators serve as barriers that support and protect conductors. They ensure safety and efficiency, preventing electrical faults. Their design and material must handle high voltage and varying temperatures. However, not all busbar insulators are created equal. Some might fail under stress, leading to costly breakdowns.

Understanding the top busbar insulators is vital for engineers and project managers. This knowledge helps in selecting the right components for specific applications. Mistakes in choice can lead to significant consequences. As the industry evolves, staying informed will remain a challenge and a necessity.

Busbar insulators play a critical role in electrical systems. They offer support and separation between conductive parts. In doing so, they ensure safety and reliability. Understanding their importance can enhance system performance.

These insulators are designed to resist electrical currents. High insulation strength is vital. They prevent accidental short circuits and electrical failures. Proper selection matters. A mismatch can lead to insulation breakdown.

Tip: Always assess the environmental conditions. Humidity and temperature can influence insulator performance. Regular maintenance checks are essential to avoid unexpected failures.

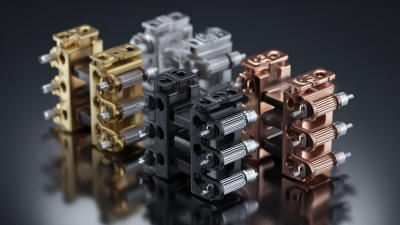

Moreover, the materials used in busbar insulation vary. Common options include glass, porcelain, and synthetic materials. Each has its advantages and drawbacks. For instance, porcelain is durable, but can be brittle. Synthetic materials may offer better resistance to weather changes but can degrade over time.

Tip: Consider the application needs when selecting materials. Evaluate load capacities and installation locations. Understanding these factors is crucial for long-term reliability. Flexibility in material choice allows for tailored solutions, but be aware of potential shortcomings.

Busbar insulators play a vital role in electrical systems. They provide support and electrical insulation. Several materials are commonly used in these insulators: porcelain, glass, and various polymers. Each has unique properties that affect performance and longevity.

Porcelain insulators are known for their high dielectric strength. They can handle extreme temperatures. However, they are also prone to chipping and cracking. This makes maintenance a concern. In contrast, glass insulators offer excellent durability. They resist environmental degradation but may be heavier, posing installation challenges.

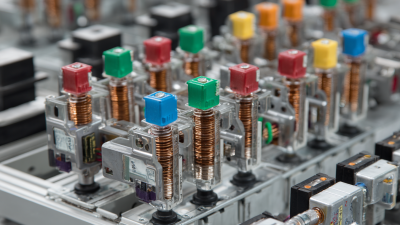

Polymer insulators, including silicone and EPDM, are gaining popularity. They are lightweight and flexible. This versatility allows for easier installation. However, their long-term performance under extreme conditions remains under scrutiny. The industry's shift toward more modern materials brings both benefits and doubts. Gathering data on durability and efficiency is crucial for future designs.

When selecting busbar insulators, several key factors come into play. Material quality is paramount. Most insulators are made from epoxy resin or silicone rubber. These materials provide excellent electrical insulation and mechanical strength. However, consider their thermal stability as well. High temperatures can affect their performance.

Tip: Check the material's dielectric strength. This helps ensure they can handle the electrical loads effectively.

Environmental conditions are another aspect to ponder. Busbar insulators are often exposed to moisture, dust, and pollutants. The chosen material must resist degradation over time. Look for features that promote self-cleaning or hydrophobic properties.

Tip: Don’t overlook the installation environment. Indoor and outdoor applications can significantly impact the type needed.

Cost is frequently a key deciding factor. However, cheaper options may not always be the best in the long run. Think about the potential maintenance costs. Sometimes, investing more upfront leads to greater savings over time.

Tip: Evaluate the cost versus the expected lifespan. Ensure the choice aligns with your budget and project goals.

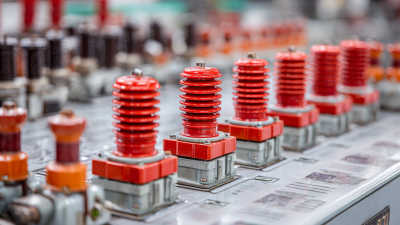

Busbar insulators play a crucial role in electrical distribution systems. These components ensure safety and reliability by preventing electrical leakage and short circuits. Their design and materials have an impact on overall system performance. Various reports suggest that the global busbar insulator market is projected to grow by 7% annually. This growth underscores the increasing demand for durable and effective insulating materials.

Key features of busbar insulators include high dielectric strength and thermal resistance. They can operate efficiently across a wide temperature range, from -40°C to 120°C. Some types exhibit superior resistance to mechanical stress. This is crucial in environments where vibrations and impacts occur. Despite advancements, some insulators still show degradation over time. This raises questions about longevity and maintenance.

Material choice is vital. Commonly, silicone, epoxy, and glass are used due to their strong insulating properties. Each material has its downsides. Silicone can be prone to dirt accumulation. Epoxy might crack under extreme stress. Glass, while strong, can be heavier and more fragile compared to other options. Choosing the right insulator is not straightforward but is essential for system effectiveness. Ultimately, understanding the specific features and specifications of different busbar insulators leads to better decision-making in electrical infrastructure design.

| Insulator Type | Material | Voltage Rating (kV) | Temperature Range (°C) | Dielectric Strength (kV/mm) |

|---|---|---|---|---|

| Porcelain Insulator | Porcelain | 36 | -40 to 120 | 60 |

| Polymer Insulator | Polymer | 24 | -30 to 90 | 30 |

| Glass Insulator | Glass | 15 | -40 to 70 | 40 |

| Composite Insulator | Composite | 30 | -40 to 120 | 50 |

| Silicone Insulator | Silicone Rubber | 20 | -40 to 100 | 35 |

| Ceramic Insulator | Ceramic | 33 | -40 to 110 | 45 |

| PTFE Insulator | PTFE | 15 | -200 to 260 | 25 |

| Resin Insulator | Resin | 10 | -40 to 80 | 20 |

| Vacuum Insulator | Metal-Glass | 50 | -40 to 150 | 70 |

| Bushing Insulator | Ceramic/Composite | 25 | -40 to 100 | 35 |

Busbar insulators play a critical role in electrical systems. They are vital for maintaining safety and efficiency. These insulators help prevent electrical faults that can cause major disruptions. Their applications are diverse and essential across various sectors.

In power distribution, busbar insulators support conductors while preventing short circuits. They minimize the risk of electrical arcing, which can lead to serious accidents. In high-voltage environments, proper insulation is crucial. It can safeguard equipment and ensure seamless operations.

Besides power distribution, these insulators are found in industrial machinery. They help maintain proper spacing and alignment of conductors. However, not all installations result in optimal performance. Sometimes, the choice of materials or design can lead to issues. Ongoing evaluation is key to enhancing reliability in electrical systems.