Leave Your Message

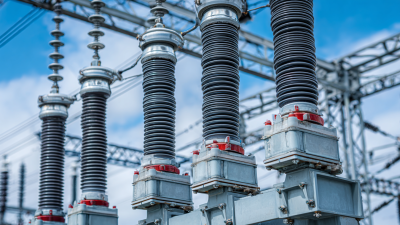

When it comes to ensuring the reliability and safety of electrical distribution systems, selecting the appropriate Medium Voltage Post Insulator is of paramount importance. These insulators play a critical role in supporting overhead lines and substations while providing necessary electrical insulation to prevent short circuits and equipment failure. The right choice can greatly influence the durability and performance of the electrical infrastructure, making it essential for engineers and project managers to understand the key factors involved in this decision-making process.

Choosing a Medium Voltage Post Insulator involves several considerations, including material composition, environmental conditions, and mechanical strength. Factors such as the specific voltage rating, pollution level of the installation site, and installation height will all impact the effectiveness of the insulator. Additionally, understanding the applications and potential challenges can help ensure that the selected insulator meets the demands of both current and future electrical systems. This guide aims to provide essential tips and insights that will facilitate the selection of suitable Medium Voltage Post Insulators tailored to meet diverse operational needs.

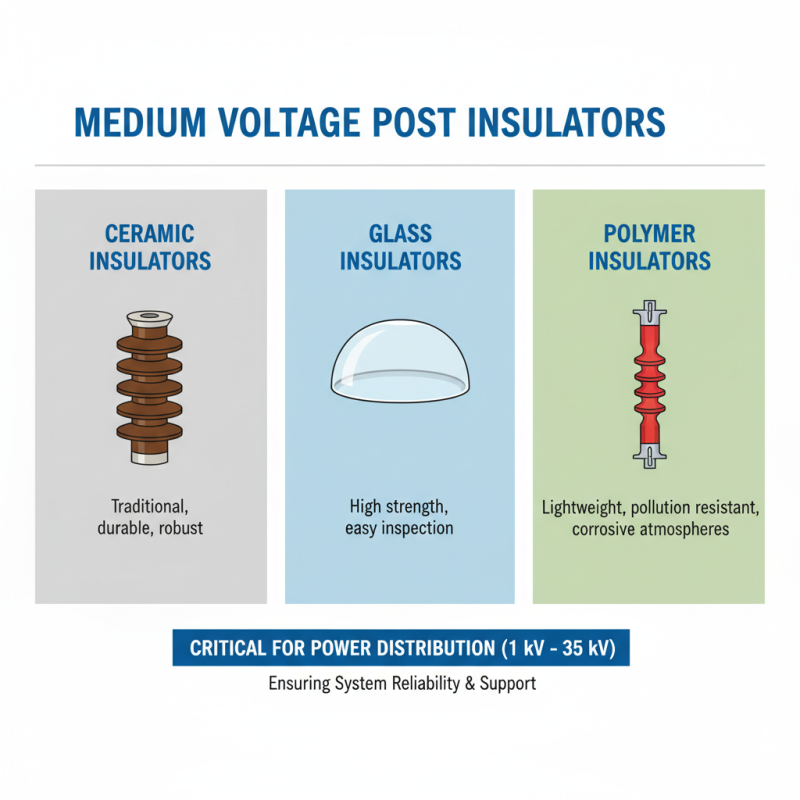

Medium voltage post insulators are crucial components in electrical systems, serving to support and insulate overhead conductors and equipment at voltages typically ranging from 1kV to 35kV. These insulators are designed to withstand environmental stresses, including moisture, pollution, and extreme temperatures, ensuring the reliable operation of power lines. Understanding the characteristics of medium voltage post insulators is essential for selecting the right type for specific applications, as their performance can significantly impact the overall reliability of the electrical network.

When choosing a medium voltage post insulator, it is important to consider factors such as the material used, mechanical strength, and electrical performance. Common materials include porcelain, glass, and polymer composites, each offering unique benefits in terms of durability and resistance to weathering. Additionally, the insulator’s electrical strength must align with the operational requirements of the system, ensuring proper insulation under various conditions.

Furthermore, assessing the application environment can guide decisions on the best insulator type, whether it be in urban settings with high pollution levels or in remote areas with lower environmental stresses.

When selecting insulator materials for medium voltage post insulators, several key factors should be evaluated to ensure optimal performance and longevity. First and foremost, the electrical properties of the material are critical. Insulators must possess high dielectric strength to prevent electrical breakdown and ensure reliable operation in various environmental conditions. Materials such as porcelain and composite polymers have distinct electrical characteristics; hence, it's vital to analyze the specific voltage requirements and environmental stresses they will face.

Moreover, mechanical strength and durability should not be overlooked. Insulators are often subjected to harsh weather, including extreme temperatures, moisture, and mechanical stress from wind or vibrations. Selecting materials that offer resistance to these factors is essential for maintaining structural integrity and performance over time. Additionally, corrosion resistance is a significant consideration, especially in coastal or industrial areas where environmental factors can degrade material quality. Evaluating these characteristics will guide you in choosing an insulator that aligns with your operational demands and environmental challenges, ultimately enhancing the reliability and efficiency of your electrical system.

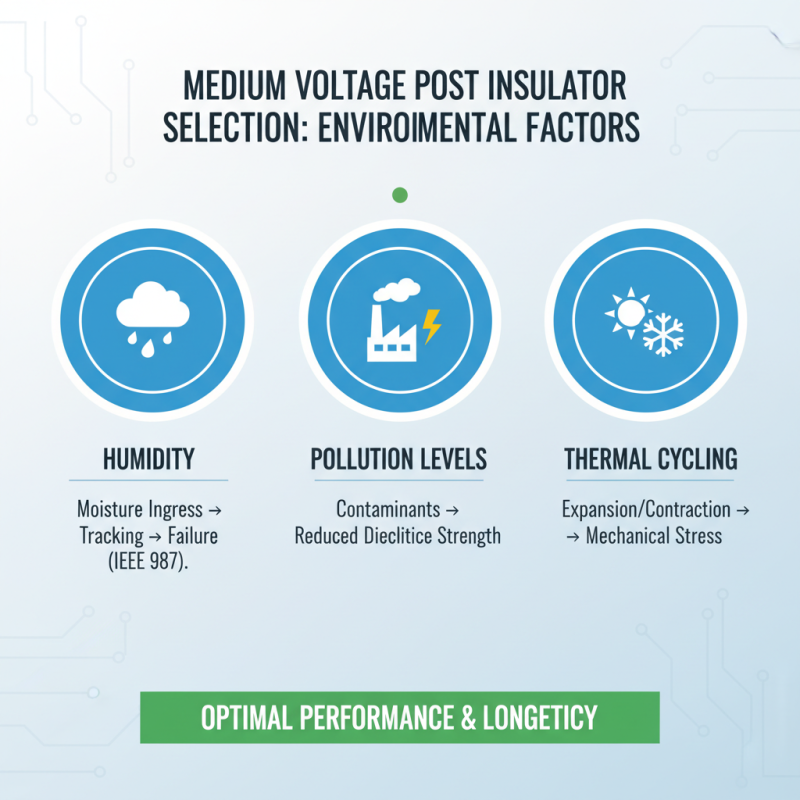

When selecting a medium voltage post insulator, understanding environmental conditions is paramount to ensure optimal performance and longevity. Factors such as humidity, pollution levels, and thermal cycling can significantly affect the insulator's dielectric strength and mechanical integrity. For instance, according to the IEEE Standard 987, insulators installed in high-humidity areas are susceptible to moisture ingress, which can lead to tracking and eventual failure if not adequately addressed.

Moreover, pollution severity is categorized under different classes, with C, D, and E defined by the American National Standards Institute (ANSI) based on the concentration of pollutants. In regions where pollution is prevalent, using insulators with higher creepage distances and special coatings can enhance resilience against environmental deterioration. A report from the International Electrotechnical Commission (IEC) highlights that post insulators subjected to severe environmental stressors have a higher incidence of failure if not chosen precisely according to local conditions. Consequently, conducting a thorough environmental assessment will inform the selection process, ensuring that the insulator meets the unique challenges presented by the installation site and maintains reliability over time.

Medium voltage post insulators are critical components in electrical distribution systems, designed to provide electrical isolation and mechanical support for conductors operating at voltages between 1 kV and 35 kV. The choice of an appropriate insulator is crucial for ensuring system reliability and performance. Common types include ceramic, glass, and polymer insulators, each possessing unique characteristics suited to specific applications. According to a report from the International Journal of Electrical Power & Energy Systems, polymer insulators, for instance, have gained popularity due to their lightweight and high resistance to environmental stress, making them particularly effective in corrosive atmospheres.

When selecting a medium voltage post insulator, it is essential to consider the application environment. For example, ceramic insulators, while heavier and more fragile, offer excellent thermal stability and are often used in high-voltage applications prone to extreme temperature fluctuations. In contrast, glass insulators provide high levels of mechanical strength and visibility, beneficial for monitoring insulator conditions but can be susceptible to vandalism. A recent study published by the IEEE Power and Energy Society indicates that varying insulation materials can influence the frequency of failure rates in different climate zones. Hence, it is imperative to match the insulator type not only with the voltage requirements but also with the specific environmental conditions of the installation site.

When selecting a medium voltage post insulator,

maintenance and safety are critical considerations that cannot be overlooked. Regular inspections

of insulators can prevent potential failures that might lead to unplanned outages or hazardous

situations. Parameters such as physical degradation, contamination from environmental factors,

and mechanical integrity should be routinely assessed. A comprehensive maintenance schedule that

includes cleaning, visual inspections, and the timely replacement of damaged components can

significantly extend the lifespan of insulators and enhance their reliability.

Safety considerations are paramount in the deployment of post insulators.

Proper installation practices must be adhered to, ensuring that the insulators are securely mounted

and correctly aligned to prevent electrical arcing or unintended contact. Additionally, personnel

must follow established safety protocols when working near high-voltage systems, which include

wearing appropriate personal protective equipment (PPE)

and utilizing insulated tools. Training for operators and maintenance staff is essential to promote

awareness of electrical hazards and the proper handling of equipment. Through diligent maintenance

and strict adherence to safety guidelines, the risks associated with high-voltage systems can be greatly minimized.