Leave Your Message

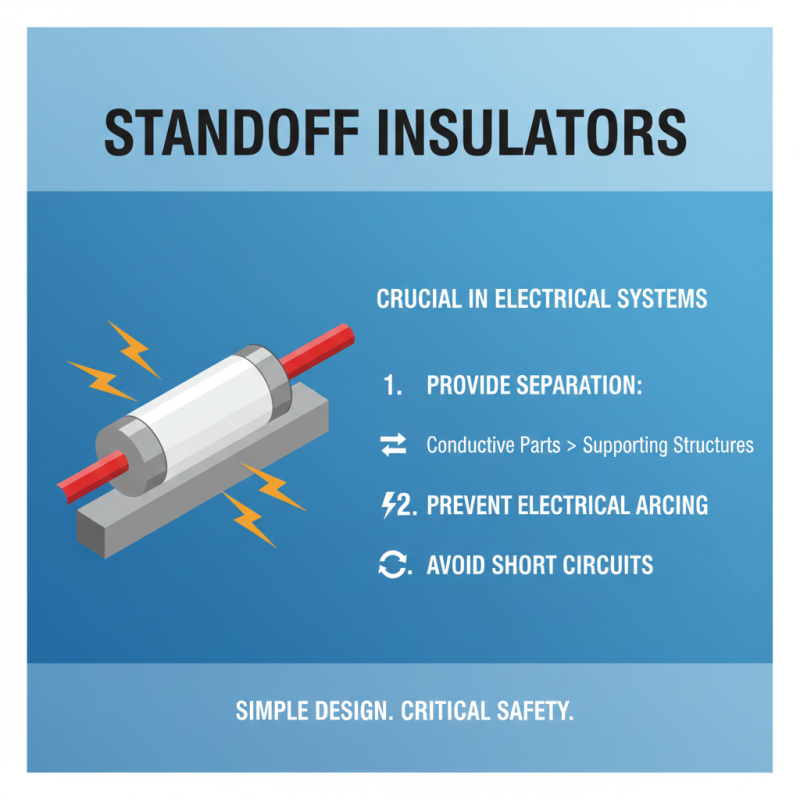

Standoff insulators play an essential role in electrical systems. They are crucial for maintaining proper distances between energized components and structures. According to a report by the International Electrical Insulation Association, the market for standoff insulators is projected to grow at a CAGR of 5% over the next five years. This reflects the increasing demand for reliable and safe electrical infrastructure.

Dr. Emily Carter, an expert in electrical insulation technology, states, "Standoff insulators are vital for reducing electrical faults and enhancing system safety." Her words highlight the importance of standoff insulators in preventing failures. These components not only protect against short circuits but also improve overall system performance.

The application of standoff insulators varies across industries. They are used in power distribution, telecommunications, and renewable energy sectors. However, some challenges remain. Proper installation and maintenance are often overlooked. This neglect can lead to significant issues, highlighting the need for awareness in this field.

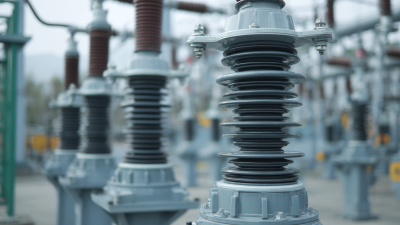

Standoff insulators play a critical role in electrical engineering. They are used in overhead power lines, which need proper insulation to prevent short circuits. These devices create a gap between the power line and the supporting structure, such as a tower or pole. This gap helps to avoid any unwanted electrical discharge.

According to industry reports, standoff insulators can significantly reduce the risk of electrical failure. In fact, improper insulation can lead to outages that cost utilities millions each year. For instance, a survey revealed that about 15% of power outages stemmed from inadequate insulation problems. Standoff insulators are crucial in enhancing the reliability of electrical systems.

Different materials are used to manufacture them, but porcelain and polymer are the most common. Each material has its pros and cons. Porcelain, while robust, is heavier and can break easily. Polymer is lighter but may degrade faster under ultraviolet light exposure. This trade-off indicates that not every choice will fit every environment. As industries evolve, there is a need for continuous innovation in this area.

Standoff insulators play a crucial role in electrical systems by maintaining the necessary separation between live conductors and supporting structures. Various types exist, each tailored for specific applications. Common materials used include porcelain, glass, and polymer composites. These materials offer unique benefits and challenges. Porcelain is durable but can be brittle, requiring careful handling. Glass provides transparency for inspection yet can suffer from thermal shock.

Polymer composites are gaining popularity. They are lightweight and resistant to environmental degradation. However, their long-term performance still raises questions. Reports suggest that polymer-based insulators show promise in reducing maintenance costs by up to 30%. Yet, some users express concern over their longevity compared to traditional materials.

In outdoor applications, the choice of material affects performance under harsh weather. Porcelain insulators can withstand extreme temperatures, but may not perform well in humid conditions. Conversely, polymer insulators fare better in humidity but can degrade under UV exposure. The decision on which type to use often depends on specific environmental factors and application requirements. Industry studies indicate that choosing the right standoff insulator can lead to significant improvements in system reliability and safety.

| Insulator Type | Material | Typical Use | Maximum Voltage (kV) |

|---|---|---|---|

| Porcelain Insulator | Porcelain | Transmission Lines | 110 |

| Glass Insulator | Tempered Glass | Substations | 66 |

| Polymer Insulator | Composite Material | Modern Power Lines | 132 |

| Silicone Insulator | Silicone Rubber | Wind Farms | 72.5 |

| Ceramic Insulator | Ceramic | Distribution Lines | 35 |

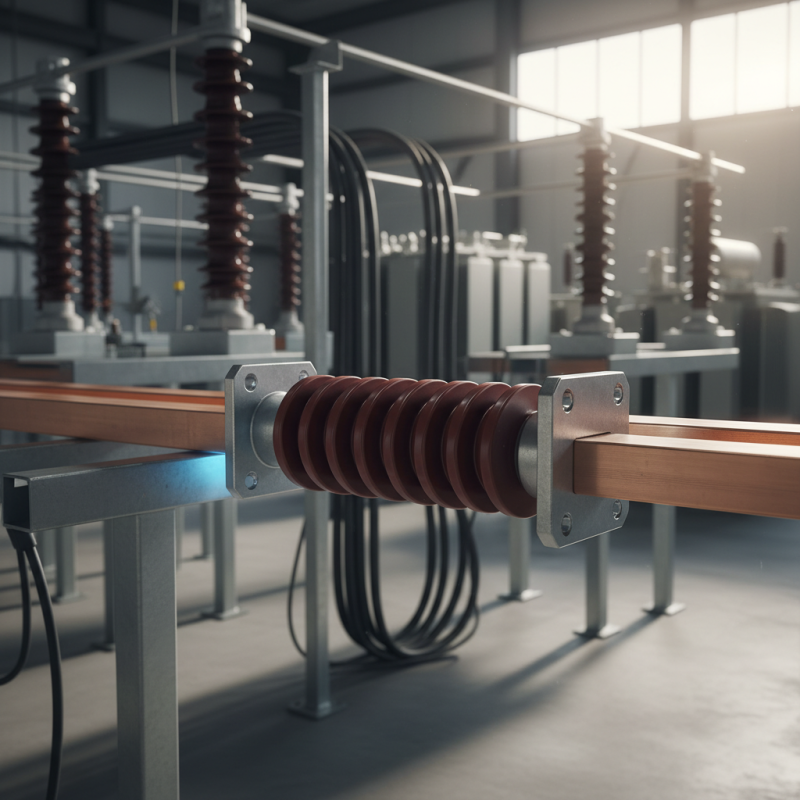

Standoff insulators are crucial in electrical systems. They provide the necessary separation between conductive parts and supporting structures. This separation helps prevent electrical arcing and short circuits. A standoff insulator typically has a simple design yet plays a significant role in ensuring system safety.

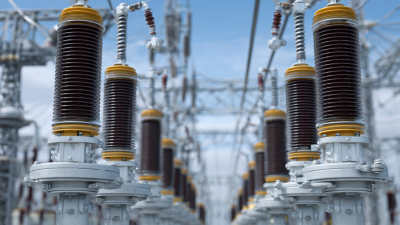

In overhead power lines, standoff insulators are widely used. They support conductors and keep them away from poles. This helps maintain a safe distance to avoid contact with tree branches or buildings. Additionally, in substations, these insulators help support busbars and other high voltage equipment. Proper installation is essential. If positioned incorrectly, issues may arise, leading to maintenance concerns.

In communication towers, standoff insulators again find their place. They help isolate antennas from the metal structure. This protects the system from potential damage caused by lightning strikes. Yet, the environment can impact these insulators over time. Regular inspection is necessary to ensure durability and performance, as wear and tear can diminish effectiveness.

Standoff insulators are crucial in electrical engineering. Their role is to support and insulate electrical conductors from structures. They maintain a safe distance, reducing the risk of electrical arcs. The installation of standoff insulators is common in power transmission systems. According to a report by the International Energy Agency, up to 80% of electrical insulation failures can be traced back to inadequate spacing.

Using standoff insulators offers several advantages. They improve safety by minimizing electrical hazards. This is especially important in high-voltage applications. Studies show that proper insulation spacing can enhance system reliability. In fact, having a well-designed standoff system can lead to a 25% increase in operational efficiency. This efficiency translates into lower maintenance costs and reduced downtime.

However, it's essential to select appropriate materials and designs. Not all standoff insulators perform equally. Environmental factors can impact their effectiveness. Research indicates that insulators in coastal areas may degrade faster due to salt exposure. Regular inspections and maintenance are necessary. The industry often overlooks this, leading to unexpected failures. It’s a reminder that even simple components need careful consideration.

Standoff insulators are crucial for the functionality of overhead power lines. They support conductors and maintain a safe distance from structures. Proper installation and maintenance ensure longevity and reliability. A report by the International Electrotechnical Commission states that poorly maintained standoff insulators can lead to significant power outages.

When installing standoff insulators, proper alignment is key. Insulators should resist mechanical strains and environmental challenges. The surface of the insulator must be clean to prevent contamination. Also, ensure that the insulator's hardware is tight but not over-torqued. Incorrect torque can weaken the assembly. A study revealed that 15% of failures in standoff insulators were linked to improper installation.

Tip: Regular inspections can help identify wear and tear. Look for cracks or discoloration. Address these issues early. Another tip is to use protective coatings. They can extend the lifespan of the insulators, especially in harsh environments. Keep in mind, neglecting routine maintenance can lead to costly repairs or unsafe conditions. Always prioritize safety during installation and upkeep.