Leave Your Message

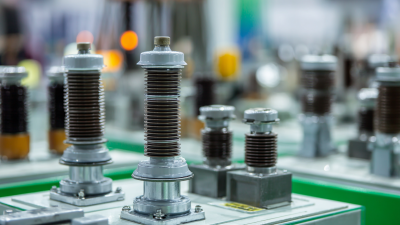

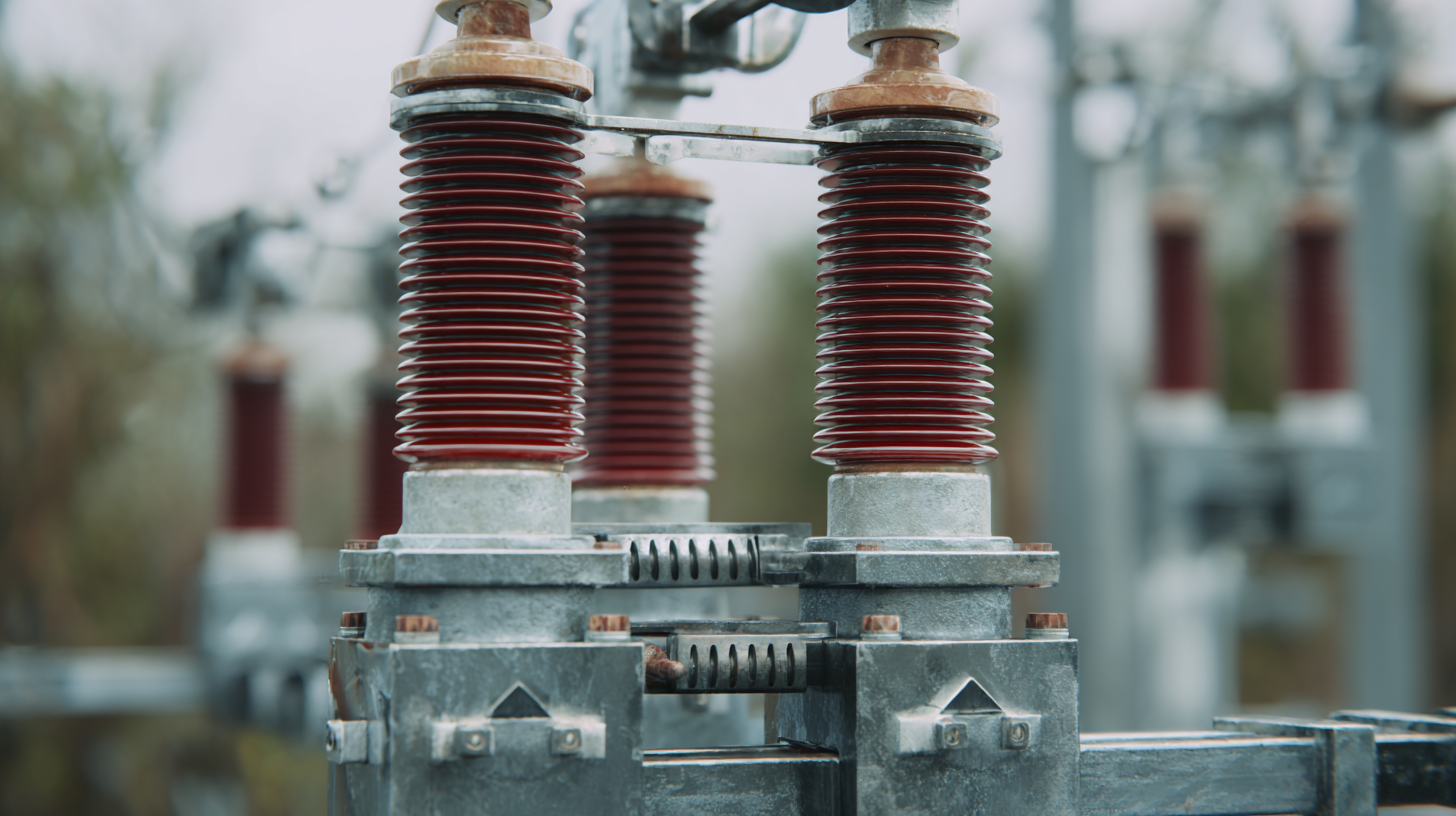

In contemporary electrical systems, the significance of Stand Off Insulators cannot be overstated. These vital components ensure reliable electrical insulation while maintaining necessary spacing between conducting elements. According to the Global Insulator Market Report 2023, the demand for high-performance insulators, particularly Stand Off Insulators, is projected to grow at a CAGR of 5.6% through 2028, driven by the increasing focus on renewable energy infrastructures and enhanced grid reliability. Stand Off Insulators play a crucial role in minimizing electrical arcing and improving safety standards, effectively addressing the challenges posed by harsh environmental conditions. As electrical networks expand and modernize, understanding the role and advancements in Stand Off Insulator technology becomes essential for engineers and designers aiming for efficient and safe power distribution.

Stand off insulators play a pivotal role in ensuring the reliability and efficiency of electrical infrastructure. These components not only maintain the necessary distance between electrical conductors and supporting structures, but they also provide essential insulation to prevent short circuits and electrical arcing. As countries like Ghana increasingly seek to improve their electrical systems, the availability of high-quality electroporcelain for insulators becomes a critical concern. The current reliance on imports underscores the need for local production and innovation in this sector.

When selecting stand off insulators, it's important to consider the material and application based on your specific needs. High voltage systems require insulators that can withstand extreme conditions while maintaining performance. Ensure you choose insulators with appropriate ratings for your installation, as this can significantly impact the longevity and effectiveness of the electrical system.

Tip: Regularly inspect insulators for signs of wear or environmental damage. Early detection can prevent costly repairs and downtime.

Additionally, the growing high voltage electric insulators market indicates a rising demand for advanced materials that enhance durability and efficiency. Stakeholders must stay informed about market trends and emerging technologies to make educated decisions that will support the infrastructure's growth and sustainability, particularly in developing regions like Ghana.

Tip: Invest in training and resources for your team to ensure proper installation and maintenance of insulators, maximizing their lifespan and operational safety.

Stand off insulators play a crucial role in modern electrical systems, ensuring the effective transmission of electrical power while providing essential insulation and mechanical support. The materials used in these insulators are vital in enhancing their performance and sustainability. Recent trends highlight a shift towards advanced ceramics and composites, which not only boast superior electrical and thermal insulation properties but also exhibit increased resistance to environmental stresses, such as UV exposure and temperature fluctuations.

According to a recent industry report, the market for stand off insulators made from sustainable materials is expected to grow by over 25% in the next five years, driven by the push for greener technologies. Innovative production techniques, including additive manufacturing and the integration of recycled materials, are paving the way for these advancements. Moreover, the adoption of high-performance polymers in insulator design is setting new standards for durability and reliability, which are essential for the rigorous demands of modern electrical infrastructures. These developments not only support the performance needs of electrical systems but also align with global sustainability goals, making them an essential focus in the evolving landscape of electrical engineering.

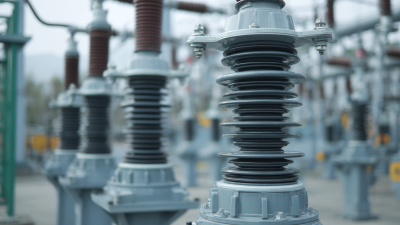

In modern electrical systems, the design of stand-off insulators plays a crucial role in ensuring operational reliability and safety. When considering the performance of these insulators, several factors come into play, including materials selection, environmental resistance, and geometrical factors. According to a recent report from the International Electrotechnical Commission (IEC), the use of advanced composite materials in insulator design can enhance their mechanical strength and electrical performance by up to 40%, providing increased durability against harsh environmental conditions.

Moreover, the shape and spacing of stand-off insulators significantly affect their performance under electrical stress. A study published in the "IEEE Transactions on Power Delivery" indicated that optimizing the geometrical configurations can reduce the electric field concentration around insulators, leading to a decrease in flashover incidents by 30%. This highlights the importance of careful design consideration to not only prolong the lifespan of the insulators but also enhance overall system efficiency and reliability. By integrating these design considerations into the development of insulators, engineers can effectively address the challenges posed by modern electrical grid demands.

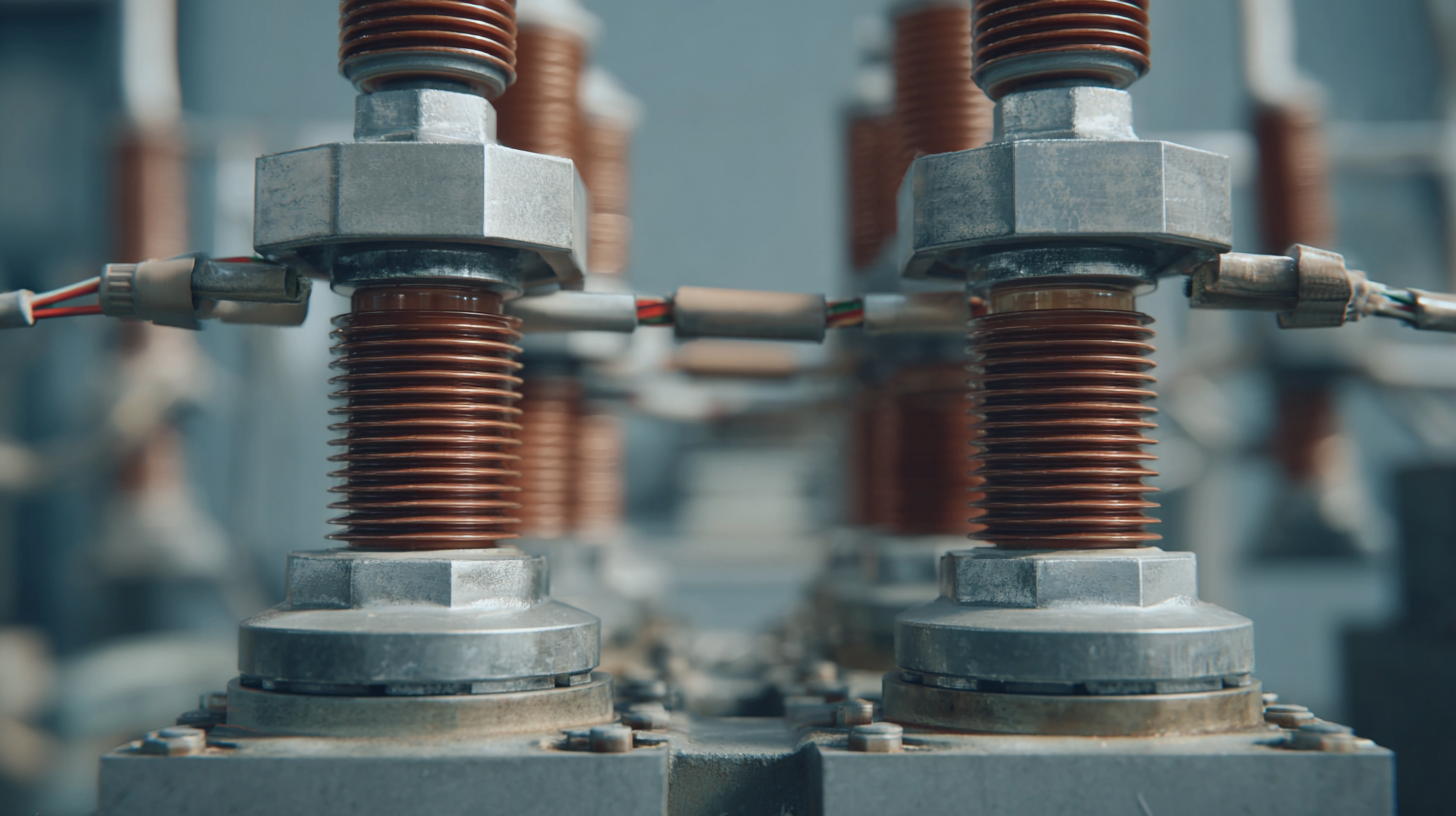

Proper maintenance of stand-off insulators is crucial for ensuring their longevity and optimal performance in electrical systems. One of the primary actions for extending the lifespan of these insulators is regular inspection. Over time, insulators can accumulate dust, dirt, and other contaminants that can impair their function. Routine cleaning schedules should be implemented, particularly in environments prone to pollution or severe weather conditions. Using appropriate cleaning methods, such as soft brushes and distilled water, helps prevent damage while restoring their effectiveness.

Another essential maintenance practice involves monitoring for signs of wear, such as cracks, chips, or discoloration. These visual indicators can signal underlying issues that, if not addressed promptly, may lead to premature failure. Additionally, it is important to check the installation integrity of the insulators, ensuring that they are securely mounted and not subjected to undue mechanical stress.

Implementing these proactive measures will significantly contribute to the reliability and durability of stand-off insulators, thereby enhancing the overall performance of modern electrical systems.

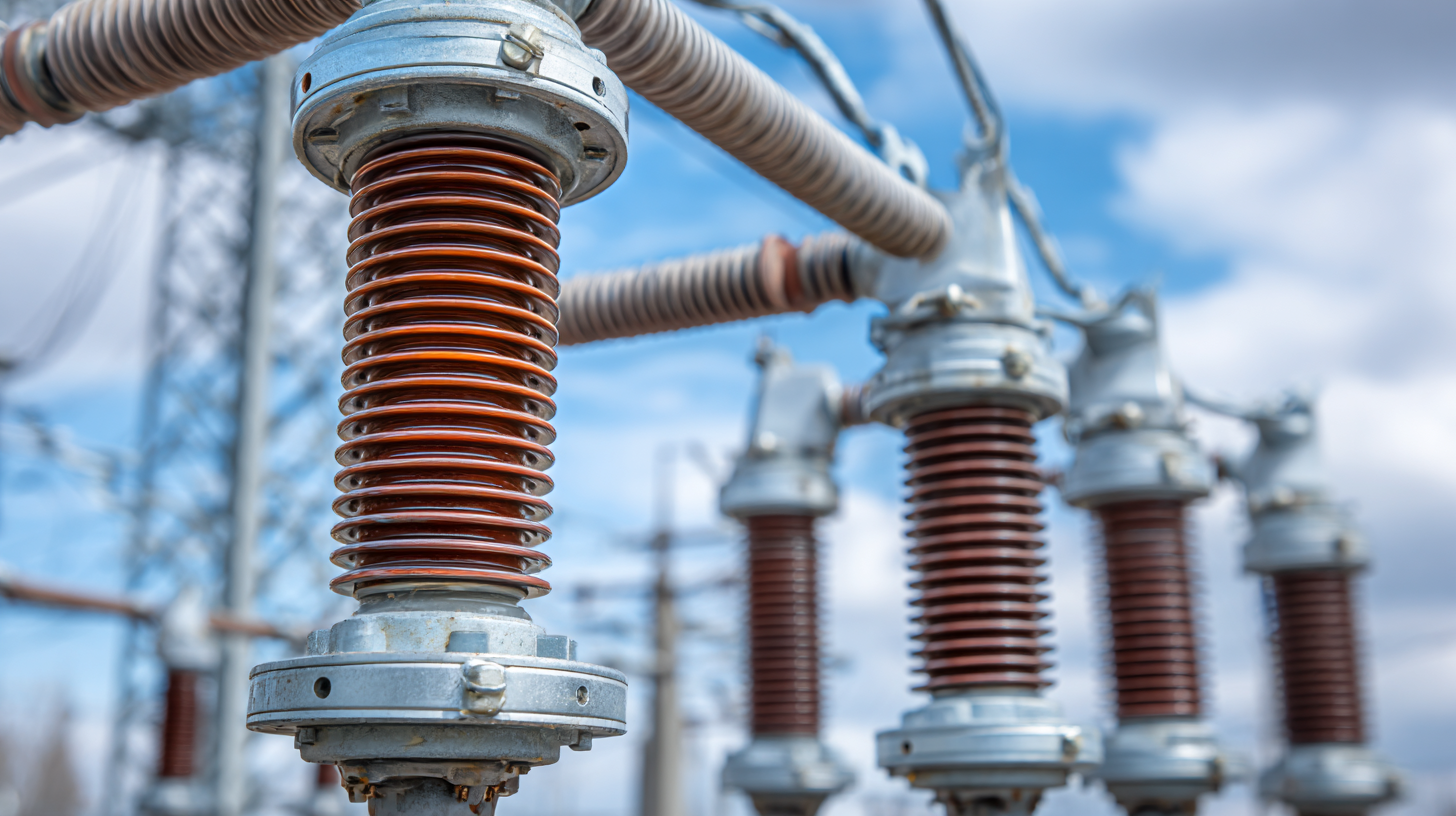

Innovative technologies are significantly enhancing the efficiency of stand-off insulators, which are critical components in modern electrical systems. According to the International Electrification Commission (IEC), the demand for advanced insulator technologies will grow by approximately 4.3% annually through 2025. This growth can be largely attributed to the increasing reliance on renewable energy sources, alongside the need for greater insulation reliability in harsh environments.

The integration of materials like silicone and advanced polymers into the design of stand-off insulators is one key innovation. These materials exhibit superior hydrophobicity and UV resistance compared to traditional ceramics, leading to improved performance under varied climate conditions. A report by the IEEE states that the usage of composite insulators can decrease flashover rates by up to 60%, thereby increasing system stability and reducing maintenance costs.

Moreover, the adoption of smart technology in insulator monitoring systems allows for real-time assessments of insulator health, further ensuring reliability in transmission networks. Such technological advancements are not only making stand-off insulators more efficient but also more sustainable in the long run.