Leave Your Message

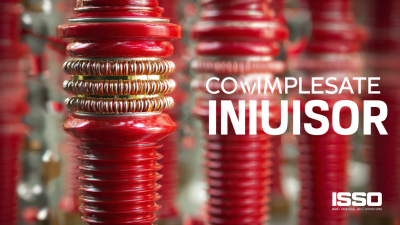

In the increasingly competitive landscape of electrical engineering and construction, optimizing efficiency in project implementation is paramount. Standoff insulators play a crucial role in ensuring the safety and reliability of overhead transmission lines and other electrical infrastructure. According to a recent report by the International Electric Power Research Institute, the correct usage of standoff insulators can reduce maintenance costs by up to 30% and extend the lifecycle of electrical systems by an additional 10 years. However, many projects still encounter common pitfalls such as inadequate spacing and improper material selection, which can jeopardize operational effectiveness. By addressing these challenges and adopting proven strategies, professionals can maximize efficiency and enhance the performance of their projects involving standoff insulators.

Standoff insulators are crucial components in various engineering and construction projects, designed to provide electrical insulation while maintaining structural integrity. Their primary features include durability, resistance to environmental factors, and the ability to withstand mechanical stresses. These characteristics not only enhance safety but also reduce maintenance costs over time. Understanding the benefits of standoff insulators can significantly impact the success of your projects, ensuring a reliable and efficient performance.

The advantages of using standoff insulators extend beyond mere functionality; they play a vital role in optimizing project efficiency. By integrating these insulators, project managers can minimize downtime associated with failures and repairs. Additionally, their lightweight properties can lead to easier handling and installation, further accelerating project timelines. As industries face increasing pressures to deliver faster and more cost-effective solutions, the strategic application of standoff insulators is becoming more critical than ever, providing a competitive edge in a landscape often marked by economic fluctuations and supply chain challenges.

| Dimension | Value | Benefit |

|---|---|---|

| Material Type | Polymer Composites | Lightweight and durable |

| Voltage Rating | 15 kV to 1 MV | Suitable for high voltage applications |

| Operating Temperature | -40°C to 90°C | Wide range for diverse environments |

| Mechanical Strength | > 100 MPa | Resistant to mechanical stress |

| Insulation Resistance | > 1000 MΩ | Enhanced electrical safety |

When selecting standoff insulators for your project, it's crucial to prioritize both functionality and safety. Insulation optimization can significantly enhance the overall safety of electrical systems while reducing the risk of corrosion, a common concern in environments exposed to moisture and varying temperatures. According to industry reports, proper insulator selection can lead to a reduction in failure rates by up to 30%, showcasing the importance of making informed choices tailored to your project’s specific needs.

Moreover, understanding the thermal and electrical properties of various standoff insulators is essential. The project team often relies on conservative assumptions due to limited data, which can lead to inefficient designs. Incorporating advanced modeling techniques and material databases can provide vital insights into the performance of different insulator options. Recent advancements in insulating materials have demonstrated potential efficiency gains of over 20%, emphasizing the need for thorough research and analysis in the design phase to ensure optimal results. By identifying the right standoff insulators, project teams can not only enhance safety but also achieve significant cost savings and improved project timelines.

When it comes to the installation and maintenance of standoff insulators, adhering to best practices can significantly enhance their efficiency and longevity in your projects. Firstly, it's crucial to select the right type of standoff insulator based on the environmental conditions and application requirements. Insulators should be made from durable materials that can withstand temperature fluctuations, moisture, and mechanical stress. Properly securing the insulators during installation is equally important, as loose fittings can lead to vibrations that may compromise performance.

Regular maintenance is essential for ensuring the ongoing effectiveness of standoff insulators. This includes routine inspections for signs of wear, corrosion, and other damage. Cleaning the insulators to remove dirt and debris is another vital task, as contaminants can affect their insulating properties. Additionally, keeping an eye on the electrical connections and ensuring they are tight and free from oxidation will help in maximizing the performance of your system. By following these installation and maintenance best practices, you can ensure that your standoff insulators function optimally, contributing to the overall efficiency of your projects.

In today’s competitive landscape, managing resources effectively is paramount to enhancing project efficiency, particularly when incorporating standoff insulators. According to the Electric Power Research Institute (EPRI), optimizing resource allocation can improve project timelines by up to 30%. By strategically selecting standoff insulators that align with specific project requirements, engineers can streamline operations and reduce material wastage—a critical factor given that material costs can constitute as much as 60% of total project expenses.

Moreover, innovative resource management techniques, such as just-in-time procurement and predictive analytics, have proven invaluable in minimizing downtime. A 2022 report from the International Energy Agency (IEA) indicates that projects utilizing these strategies achieved a 40% improvement in overall efficiency. By leveraging technology to forecast material needs and labor requirements more accurately, project managers can ensure that standoff insulators are integrated seamlessly into workflows, ultimately leading to faster completion and reduced costs. Such advancements illustrate the vital connection between resource management and project success in the electrical utility sector.

In the realm of electrical engineering, standoff insulators play a critical role in ensuring both safety and efficiency across various applications. A recent industry report by the International Electrotechnical Commission indicates that the use of high-performance standoff insulators can improve system reliability by up to 30%. In the transportation sector, for instance, a leading rail infrastructure project successfully integrated standoff insulators to protect signaling systems from environmental factors, enhancing both operational uptime and longevity of equipment.

Moreover, in renewable energy installations, case studies reveal that standoff insulators have significantly contributed to the performance of solar farms. According to the Solar Energy Industries Association, projects employing standoff insulators experienced a 40% reduction in maintenance costs due to lower failure rates. By effectively managing electrical stress and environmental exposure, these insulators ensure uninterrupted energy generation, which is pivotal for meeting increasing energy demands while maintaining sustainability. The successful application of standoff insulators in such diverse industries showcases their essential role in optimizing performance and reducing operational risks.