Leave Your Message

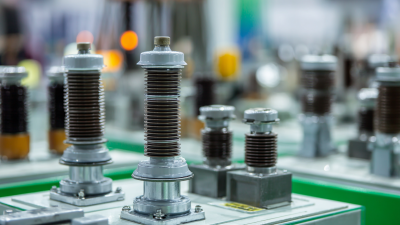

The reliability of electric grids is paramount as the demand for uninterrupted power supply continues to rise. According to the U.S. Energy Information Administration, nearly 80% of the electricity consumed in the United States is delivered through medium voltage systems, highlighting the critical role of Medium Voltage Post Insulators in maintaining grid stability. Recent studies indicate that advancements in material science and engineering technologies have significantly enhanced the performance and durability of these insulators. For instance, integrating polymers and composite materials has been shown to reduce failure rates and maintenance costs by up to 30%, thus improving overall grid reliability. With the adoption of smart grid technologies and the Internet of Things (IoT), the real-time monitoring of Medium Voltage Post Insulators becomes feasible, enabling utilities to mitigate risks before failures occur. This article explores innovative solutions aimed at optimizing the effectiveness of Medium Voltage Post Insulators, thereby contributing to a more resilient electrical infrastructure.

Medium voltage post insulators play a crucial role in enhancing grid reliability, especially in today's increasingly complex electrical networks. With the rising demand for electricity and the integration of renewable energy sources, the design and quality of insulation materials have become pivotal. According to the IEEE (Institute of Electrical and Electronics Engineers) reports, advanced designs of medium voltage insulators have demonstrated a significant reduction in electrical failures, leading to decreased outage frequencies by up to 40% in well-implemented systems.

The use of advanced materials and engineering techniques has also led to the development of insulators that can withstand harsh environmental conditions. Data from the Electric Power Research Institute shows that innovations such as composite insulators have improved performance under extreme temperatures and pollution levels. By enhancing the overall durability and reliability of medium voltage systems, utilities are not only ensuring continuous power supply but also optimizing maintenance costs, which can drop by 25% with the adoption of these enhanced technologies. As electric grids evolve, investing in improved post insulator designs will be vital for achieving long-term operational efficiency.

| Category | Specification | Benefits | Application Areas |

|---|---|---|---|

| Material Type | Composite Insulators | Enhanced resistance to environmental stress | High Voltage Applications |

| Voltage Rating | 10-36 kV | Suitable for medium voltage distribution networks | Urban Grid Systems |

| Weather Resistance | UV and Moisture Resistant | Longer lifespan and reduced maintenance | Rural Areas |

| Ease of Installation | Modular Design | Quicker to install and replace | Construction Projects |

| Compliance Standards | IEC and ANSI | Ensures safety and reliability | Utility Infrastructure |

Assessing the reliability of medium voltage post insulators in power distribution is crucial for enhancing grid performance. Key performance metrics such as voltage withstand capabilities, thermal stability, and mechanical strength are essential.

Voltage withstand tests gauge an insulator's ability to endure high voltage stress without failure, ensuring that it can function effectively under operational conditions.

Thermal stability measures how well the insulator can handle fluctuations in temperature, which is vital in preventing thermal breakdown and maintaining consistent performance.

Assessing the reliability of medium voltage post insulators in power distribution is crucial for enhancing grid performance. Key performance metrics such as voltage withstand capabilities, thermal stability, and mechanical strength are essential.

Voltage withstand tests gauge an insulator's ability to endure high voltage stress without failure, ensuring that it can function effectively under operational conditions.

Thermal stability measures how well the insulator can handle fluctuations in temperature, which is vital in preventing thermal breakdown and maintaining consistent performance.

Additionally, mechanical strength tests evaluate the impact of environmental factors, such as wind and ice load, on insulator reliability. A robust mechanical design ensures that insulators can withstand these stresses over time without compromising their integrity. By focusing on these performance metrics, utilities can select advanced technologies and materials that not only meet current demands but also enhance the overall reliability of the power distribution system. Incorporating these assessments into the maintenance and installation practices can significantly reduce outages and improve service reliability.

The surge in renewable energy adoption has prompted a significant transformation in the insulator materials used in medium voltage applications. Emerging technologies are driving innovations that enhance grid reliability and efficiency. Advanced composite materials are being developed to improve the performance and lifespan of post insulators. These materials not only offer superior electrical insulation properties but also increase resistance to environmental stressors, such as humidity and temperature fluctuations.

As the demand for cleaner energy solutions grows, the focus on sustainable practices in insulator manufacturing has intensified. Manufacturers are incorporating eco-friendly materials and production processes, which not only supports environmental goals but also contributes to market growth. By prioritizing sustainability, these innovations in medium voltage insulators are ensuring that utility infrastructures can meet the evolving demands of renewable energy systems, maintaining grid stability while minimizing ecological impact.

Upgrading medium voltage post insulators with advanced technology can significantly reduce outages and maintenance costs in power distribution systems. Traditional insulators often suffer from performance issues due to environmental stresses and aging, leading to frequent failures. By employing newer materials and innovative designs, utilities can enhance insulation performance, thereby minimizing the risk of electrical failures. This upgrade not only boosts reliability but also translates into direct savings by lowering the frequency of repairs and replacements.

Quantifying the impact of these upgrades involves analyzing historical outage data and maintenance records. Utilities can perform cost-benefit analyses that take into account reductions in downtime, the lifespan of upgraded insulators, and the associated savings from lowered maintenance interventions. By systematically tracking these metrics, organizations can establish a clear connection between insulator technology improvements and overall operational efficiency, ultimately leading to a more reliable power delivery system at reduced costs.

The integration of advanced technology in medium voltage post insulators has become crucial for enhancing grid reliability. Various utilities have successfully implemented these innovative insulators, showcasing notable improvements in their power networks. For instance, a utility in the Midwest reported a 30% decrease in outages after upgrading to high-performance composite insulators, which offer superior strength and resistance to environmental factors.

Tips for effective implementation include conducting thorough site assessments to determine the best materials for specific conditions. It's essential to select insulators that not only meet electrical performance standards but also provide durability against weather extremes. Collaborating with experienced manufacturers can guide utilities in choosing the right insulator types that align with their grid reliability goals.

Another successful case study comes from a southern region power company that incorporated smart technology into their post insulators. By using sensors embedded within the insulators, they were able to monitor performance in real time and identify potential issues before they could escalate. Emphasizing the importance of integration, utilities are encouraged to explore smart insulator technologies that enhance both reliability and efficiency in power distribution networks.