Leave Your Message

In modern power systems, the role of the Medium Voltage Insulator is crucial. With the increase in renewable energy sources, reliability is paramount. According to industry reports, over 30% of power outages are linked to insulator failures. This data emphasizes the need for robust insulators to maintain system integrity.

Medium Voltage Insulators are designed to withstand harsh environmental conditions. They ensure the transmission of electricity across diverse terrains. However, not all insulators perform equally. Recent studies indicate that nearly 15% of insulators can degrade faster than expected. The material quality and manufacturing processes heavily influence their lifespan.

Investing in high-quality Medium Voltage Insulators can enhance performance and reduce maintenance costs. Companies must reflect on their choices and the potential risks of inadequate insulators. A small oversight can lead to significant operational challenges. Thus, understanding the importance of Medium Voltage Insulators becomes essential for sustainable power systems.

Medium voltage insulators play a crucial role in power systems. They are vital for maintaining the integrity of electrical infrastructure. According to a recent industry report, improperly functioning insulators can lead to significant power outages and safety hazards. These outages may cost utilities up to $150 billion annually.

Properly designed and maintained insulators help reduce equipment failure risks. They withstand electrical stresses and environmental conditions. The International Electrotechnical Commission estimates that nearly 30% of power system failures relate to insulation issues. This data underlines the importance of choosing the right materials and types for specific applications.

Yet, challenges remain in the industry. Aging infrastructure often leads to increased vulnerability. Many systems still rely on outdated insulators that fail to meet modern demands. It raises concerns regarding reliability and efficiency. Regular inspections and updates are necessary. Investing in advanced insulator technology can mitigate risks and enhance system performance.

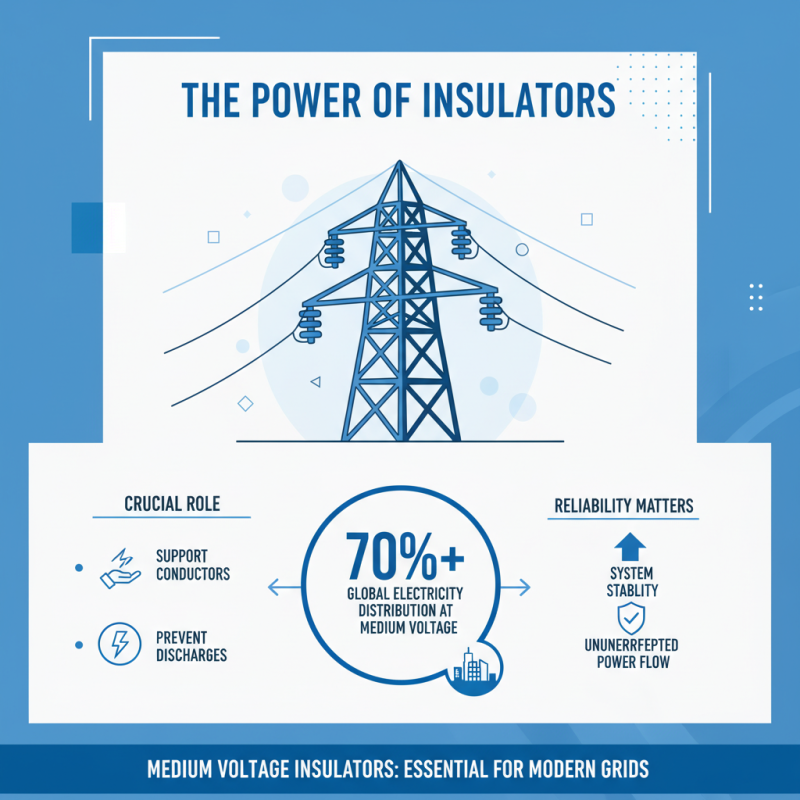

Medium voltage insulators play a crucial role in electrical systems. They support and insulate conductors, preventing unwanted electrical discharges. According to a recent industry report, over 70% of electricity distribution happens at medium voltage levels. This highlights the importance of reliable insulators.

These insulators must withstand various environmental factors, such as humidity and temperature fluctuations. A failure can lead to catastrophic outages and safety hazards. The average lifespan of medium voltage insulators is about 30 years, but extreme weather can shorten this. Investing in quality materials and regular maintenance is essential.

Electrical utilities often face challenges with aging infrastructure. Some insulators can become brittle over time, compromising their effectiveness. While innovations are being made, areas with outdated systems may struggle to maintain performance. Regular testing and monitoring can alleviate potential risks, promoting a more reliable power supply.

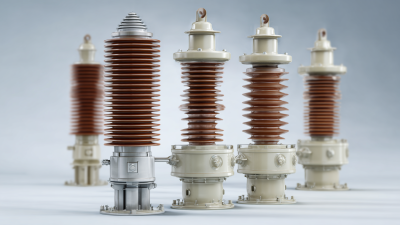

Medium voltage insulators play a crucial role in power systems. Their primary function is to support conductors and isolate them from the ground. Various types of insulators are used, including porcelain, composite, and glass. Each has unique benefits suited to different applications.

Porcelain insulators are known for their durability and resistance to environmental conditions. They can withstand severe weather. However, they can be heavy and prone to cracking. In contrast, composite insulators offer lighter weight and flexibility. They are less likely to break compared to porcelain. A report from the Electric Power Research Institute states that composite insulators can last for over 40 years with proper maintenance.

Glass insulators are transparent and provide good visibility for maintenance but can be vulnerable to vandalism.

Choosing the right insulator type is critical. The wrong choice can lead to frequent failures, causing unscheduled outages. A study by the International Energy Agency indicates that improper insulator selection can increase maintenance costs by 25%. Many utilities struggle to balance performance and cost. The field remains complex, and continuous research is essential. New materials and designs may help improve reliability in the future.

Medium voltage insulators play a crucial role in power systems. Their selection greatly influences system performance and reliability. Various factors affect the choice of these insulators, including environmental conditions, mechanical strength, and electrical performance.

Environmental factors are significant. In coastal areas, salt spray can corrode insulators, reducing their lifespan. A report from the Insulators Association indicates that insulators in such regions may require replacements every 5 to 10 years. In contrast, areas with dry or less polluted environments could see insulators last over 30 years. This vast difference highlights the importance of regional assessments when selecting materials.

Mechanical strength is another crucial consideration. Insulators must withstand not only their own weight but also environmental stressors like wind and ice. A study by the Electric Power Research Institute shows that insulators with high tensile strength can reduce failure rates by up to 40%. However, overestimating required mechanical performance can lead to unnecessary costs. Balancing strength and cost-efficiency is a challenge many engineers face, often reflecting on previous selections.

Medium voltage insulators play a crucial role in ensuring the reliability of power systems. Their performance directly affects how well electrical networks operate. According to the Electric Power Research Institute, insulator failures account for nearly 25% of all power outages. This statistic underscores the importance of maintaining high-quality insulation in power distribution.

Insulators are exposed to various environmental conditions. These can include extreme temperatures, moisture, and pollutants. When insulators degrade, they can cause electrical arcing or short circuits. This not only affects service reliability but also increases maintenance costs by 30% according to recent studies. Regular inspections, testing, and replacements are vital. Many utilities struggle to keep up with these necessary checks.

Moreover, the choice of materials is essential. Poor-quality materials lead to premature failures. It is estimated that up to 40% of insulator issues stem from inadequate design or manufacturing processes. This indicates a need for better industry standards and practices. Power companies must prioritize insulation quality to improve system reliability.

| Insulator Type | Dielectric Strength (kV/mm) | Mechanical Strength (N) | Operating Temperature (°C) | MTTF (Mean Time To Failure) (years) |

|---|---|---|---|---|

| Porcelain Insulator | 20-30 | 1000-1500 | -40 to 120 | 50 |

| Composite Insulator | 30-40 | 800-1200 | -40 to 90 | 30 |

| Glass Insulator | 15-25 | 900-1300 | -40 to 100 | 40 |