Leave Your Message

In the quest for enhanced energy efficiency across various industries, the role of heat resistant insulators has become increasingly significant. According to the U.S. Department of Energy, approximately 30% of energy consumed in buildings is attributable to heat loss and gain, highlighting the necessity for effective thermal management solutions. Heat resistant insulators, designed to withstand high temperatures while minimizing thermal conductivity, are pivotal in addressing these energy challenges. Industry reports indicate that using advanced heat resistant insulators can reduce energy consumption by up to 25%, while also prolonging the lifespan of equipment and reducing maintenance costs. By optimizing thermal performance, these materials not only contribute to substantial energy savings but also play a crucial role in sustainability efforts, making them integral to modern energy-efficient practices.

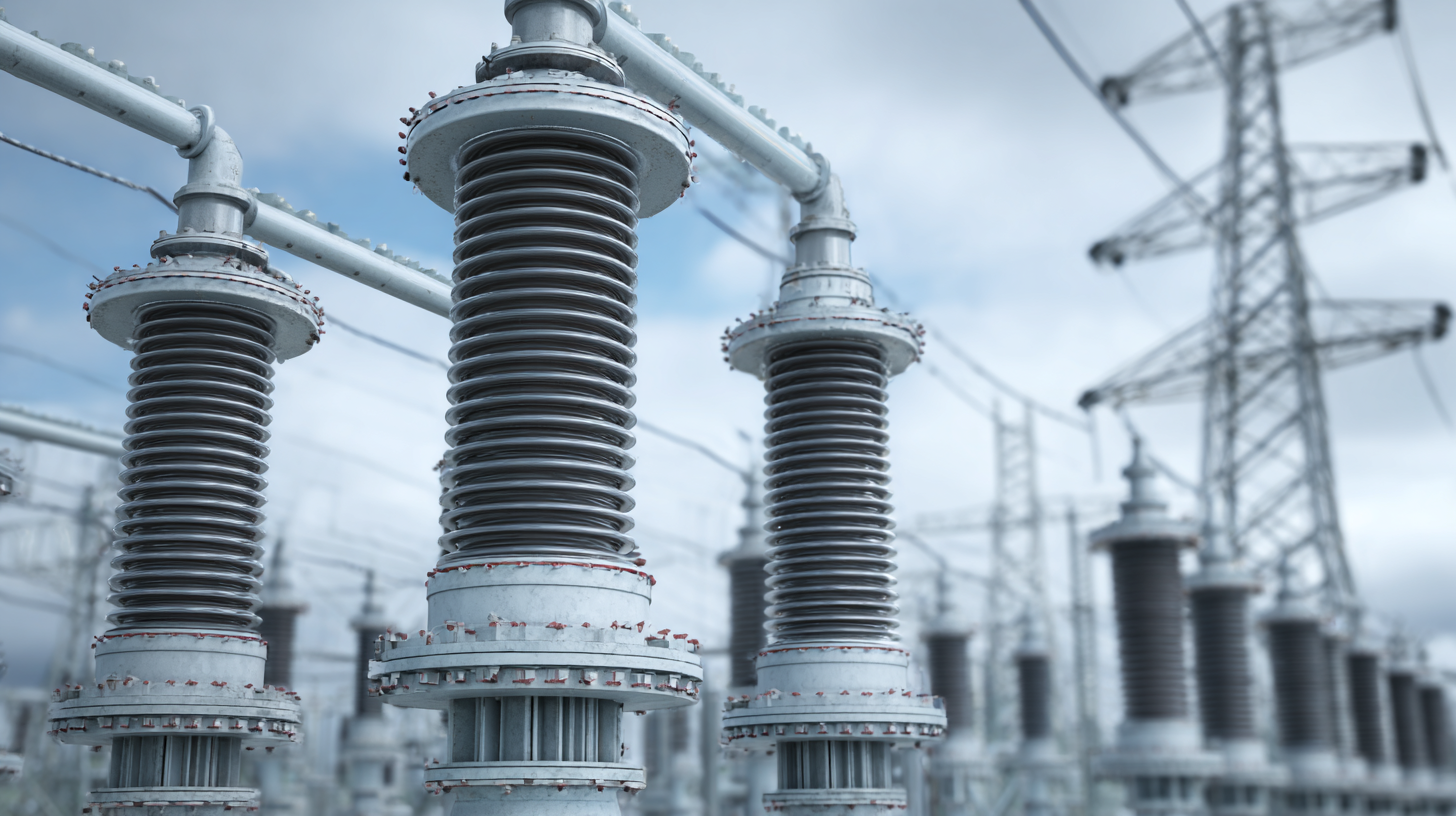

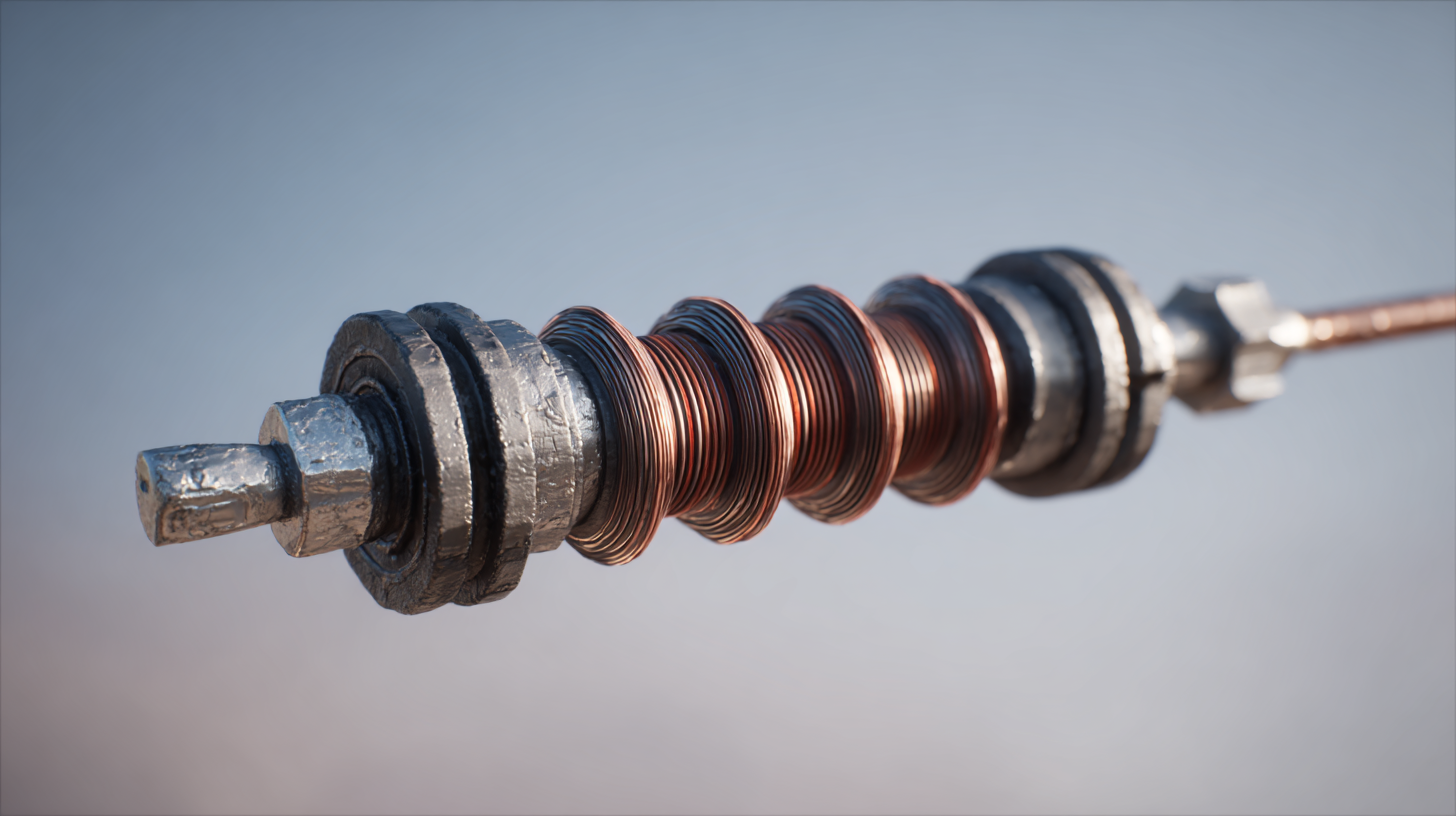

Heat-resistant insulators play a crucial role in maintaining energy efficiency across various applications, from industrial facilities to residential buildings. Understanding the mechanisms behind their heat resistance is essential to appreciating how these materials operate under extreme conditions. These insulators are typically composed of specific materials, such as ceramics, fiberglass, or mineral wool, which are engineered to withstand high temperatures without compromising their physical structure. The effectiveness of these materials stems from their low thermal conductivity, which minimizes heat transfer and creates a barrier against energy loss.

The science of heat resistance involves both the inherent properties of the insulating materials and their interactions with heat. For instance, the crystal structure of ceramic insulators allows them to endure high temperatures while maintaining stability, whereas fiberglass relies on its composition of fine glass fibers to trap air, creating an effective barrier to heat flow. Moreover, innovative manufacturing processes enhance the thermal performance of these insulators, leading to advancements in energy efficiency. By reducing heat waste in buildings and systems, heat-resistant insulators not only lower energy costs but also support sustainability goals by decreasing the carbon footprint associated with heating and cooling.

Insulators play a critical role in enhancing energy efficiency in buildings, particularly in strategies aimed at reducing energy loss. Recent studies have highlighted the potential of eco-friendly materials, such as sawdust insulation, which can significantly improve thermal resistance in hot arid climates. According to research, implementing natural insulating materials can lead to reduced energy demands, with the possibility of achieving a 20-30% decrease in energy consumption for cooling and heating in such environments. This aligns with broader goals set by sustainability initiatives to innovate construction practices that diminish the carbon footprint of buildings.

Innovations in dynamic insulation systems have also shown promising results, allowing for a controlled heat transmission rate throughout the building envelope. This methodology can adapt to changing environmental conditions, further optimizing energy use over time. A systematic review of materials like bio-based wood fiber insulation indicates that these advancements could lead to a 15% reduction in overall energy loss. As buildings continue to account for nearly one-third of global energy consumption, the integration of advanced insulators combined with eco-friendly materials is becoming increasingly vital in achieving a sustainable built environment.

Advanced heat resistant materials play a crucial role in enhancing energy efficiency across various industries. According to a report by the U.S. Department of Energy, properly insulating buildings can lead to energy savings of up to 30%. Innovations in insulators, such as aerogels and ceramic fibers, are not only capable of withstanding extreme temperatures but also minimize heat loss. These materials can significantly reduce the energy required for heating and cooling, thus directly impacting an organization’s operational costs.

Tips for implementing these advanced materials include conducting an energy audit to identify areas where heat loss is most significant. This allows for targeted insulation improvements. Additionally, choosing high-performance insulators that exceed standard insulation values can provide greater long-term savings on energy bills. Incorporating solar reflective coatings on your insulating materials can further enhance energy efficiency, particularly in retrofit projects.

Investment in heat resistant insulators is not just about compliance; it’s about achieving sustainable energy solutions. The Global Insulation Market report suggests that businesses adopting advanced insulation technology can see a return on investment within three to five years due to reduced energy costs. This shift is transforming the energy consumption landscape, leading to smarter buildings and a greener future.

Insulation technology plays a crucial role in enhancing HVAC efficiency and overall performance. The choice of insulating materials can significantly affect how much energy is consumed for heating and cooling. According to a recent industry report, the global HVAC insulation market size was estimated at USD 6.53 billion in 2024 and is projected to reach USD 9.28 billion by 2030, growing at a CAGR of 4.7%. This growth highlights a growing recognition of the importance of effective insulation in reducing energy costs and improving indoor climate management in buildings.

The impact of insulation technology is especially vital as global temperatures rise, prompting the need for more energy-efficient building designs. Elements such as roofing design, materials, and surface color can influence the workload of HVAC systems. Efficient insulation reduces the thermal load on these systems, leading to lower energy consumption. For example, innovative insulation solutions like vacuum insulation panels have emerged as effective options for minimizing heat transfer, which directly enhances HVAC performance and reduces energy costs. The U.S. HVAC insulation market size is also projected to grow at a CAGR of 4.6% from 2025 to 2030, indicating a notable shift towards more energy-efficient solutions in the HVAC sector.

Heat resistant insulators play a crucial role in optimizing energy efficiency across various industries. According to the International Energy Agency, improper insulation can lead to energy losses of up to 30% in industrial processes. In response, industry standards such as ASTM C447 provide guidelines for testing and evaluating insulative materials based on their thermal resistance, durability, and performance under extreme conditions. These standards are essential for ensuring that materials can withstand high temperatures and provide reliable insulation over time.

Applications of heat resistant insulators span from the manufacturing of industrial equipment to the construction of energy-efficient buildings. The U.S. Department of Energy highlights that the use of high-performance insulators can improve energy efficiency by integrating materials that reduce heat transfer. For instance, ceramic and mineral-based insulators are increasingly preferred for their exceptional thermal properties, with some reporting thermal conductivities as low as 0.05 W/m·K. By adhering to established industry standards and selecting appropriate heat resistant insulators, companies can significantly enhance their energy efficiency, reduce operational costs, and minimize environmental impacts.