Leave Your Message

In today's fast-paced industrial environment, selecting the right Heat Resistant Insulator is crucial for enhancing operational efficiency and ensuring safety across various sectors. With the global insulation market projected to reach $80 billion by 2027, driven by increasing demand for energy-efficient solutions and stringent regulations on energy consumption, industries are prioritizing high-performance insulation materials. Reports indicate that the construction sector alone is expected to account for over 40% of this market share, highlighting a growing awareness of the benefits provided by superior insulating technologies. Furthermore, as industries increasingly turn to sustainable practices, the demand for advanced heat resistant insulators that can withstand extreme temperatures while minimizing energy loss is at an all-time high. This ultimate guide will provide valuable insights and criteria for selecting the ideal Heat Resistant Insulator tailored to meet your industry's specific needs.

Heat resistant insulators play a crucial role across numerous industries, ensuring safety, efficiency, and performance in high-temperature environments. In sectors such as aerospace, automotive, and manufacturing, the need for materials that can withstand extreme conditions is paramount. For instance, in the aerospace industry, insulators safeguard sensitive electronic components from heat generated during flight. Without these specialized materials, the risk of failure could lead to catastrophic consequences, underscoring their significance.

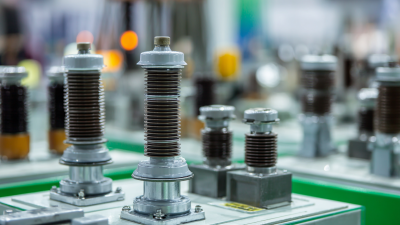

Moreover, the chemical and energy industries benefit greatly from heat resistant insulators. In chemical processing, these materials help maintain optimal temperatures, preventing unwanted reactions that could compromise safety and product integrity. In power generation, insulators protect equipment from heat loss, enhancing energy efficiency and reducing operational costs. Selecting the right heat resistant insulator not only meets regulatory standards but also contributes to the overall longevity and reliability of system components, making it an essential consideration for industry professionals.

When selecting the right heat resistant insulator for your industry needs, several key factors come into play. Firstly, the operating temperature range of the insulator is crucial. According to the U.S. Department of Energy, high-performance insulators can withstand temperatures from -50°F to over 1,800°F, making them essential in industrial applications such as aerospace and petrochemicals. Properly assessing the maximum temperature your systems will encounter ensures selection of materials that

prevent thermal failure and enhance energy efficiency.

Another critical consideration is the insulating material's thermal conductivity. A study published in the Journal of Materials Science shows that materials with lower thermal conductivity can significantly reduce heat loss, improving system efficiency by up to 40%. For industries that rely on energy conservation, such as manufacturing and power generation, investing in high-quality insulators with optimal thermal properties can yield substantial cost savings over time. Moreover, understanding industry-specific regulations and standards, such as ASTM and ISO certifications, can help ensure compliance and reliability in thermal management solutions.

The heat-resistant materials market is witnessing significant growth, driven by increasing applications across various industries, including agriculture and construction. A comparative analysis of different heat-resistant materials illustrates distinct advantages offered by each type. For instance, expanded polystyrene (EPS) and extruded polystyrene (XPS) are favored in temperature-sensitive applications due to their superior insulation properties. In agricultural contexts, these materials play a crucial role, especially in storage farms and livestock facilities, where maintaining optimal temperatures is essential for productivity. According to market reports, the agricultural insulation market is expected to grow substantially, with notable market shares for products like PIR/PU and glass wool, indicating rising investments in energy-efficient solutions.

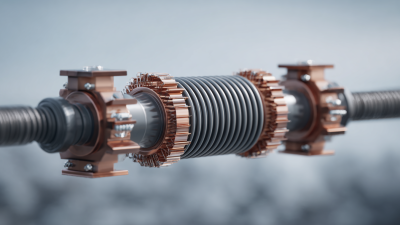

Furthermore, the advanced ceramic segment has emerged as a pivotal area within the new materials sector. Innovations in ceramics, driven by enhanced properties and applications, position them as strong contenders against traditional insulators. With the ceramics market projected to grow significantly, stakeholders are keenly exploring advanced heat-resistant ceramics that are versatile for high-temperature applications. By integrating these materials into UAV manufacturing, for instance, industries are improving their product performance while also looking into lightweight composites like carbon fiber, which dominate drone structural requirements due to their combination of strength and low weight. The ongoing trends suggest a shift towards integrating advanced materials into both existing and novel applications, capturing the attention of industries worldwide.

When it comes to heat resistant insulators, choosing the right type for specific industrial applications is crucial. In the manufacturing sector, thermal insulation is essential for protecting equipment from extreme temperatures. For example, in metal fabrication, ceramic and fiberglass insulators are commonly used to maintain safe operational temperatures and minimize energy loss, thus enhancing productivity. These materials not only withstand high temperatures but also provide durability and resistance to thermal shock.

In the oil and gas industry, heat resistant insulators are vital for pipeline insulation and equipment protection. Here, materials such as calcium silicate and mineral wool are preferred due to their superior heat resistance and ability to withstand harsh environmental conditions. These insulators not only prevent heat loss but also safeguard personnel and equipment from thermal hazards, ensuring operational efficiency. Tailoring the selection of insulators to the specific demands of each sector can significantly impact performance and safety, leading to better outcomes in industrial processes.

When it comes to the installation and maintenance of heat resistant insulators, following best practices is crucial for ensuring their longevity and effectiveness. According to a report by the National Insulation Association, properly installed insulation can reduce energy costs by 30% or more. This highlights the importance of meticulous installation processes tailored to specific industry requirements.

Tip: Before installation, always ensure that the surface is clean and dry to enhance adhesion and performance. Additionally, it's essential to select the right adhesive, as improper selection can compromise insulation integrity over time.

Regular maintenance is just as vital. The American Society of Mechanical Engineers recommends conducting annual inspections to identify any wear or damage that could impact performance. Insulating materials can degrade under extreme conditions or due to physical impact, so proactive monitoring can prevent costly downtime.

Tip: Create a maintenance schedule that includes routine checks and immediate repairs for any damage found. Implementing these best practices not only extends the lifecycle of the insulators but also optimizes overall energy efficiency in operations.

| Insulator Type | Temperature Rating (°C) | Common Applications | Thermal Conductivity (W/m·K) | Installation Method | Maintenance Recommendations |

|---|---|---|---|---|---|

| Ceramic Fiber Insulation | 1260 | Industrial furnaces, kilns | 0.1-0.2 | Bedding and wrapping | Inspect annually; replace as needed |

| Mineral Wool Insulation | 700 | Pipe insulation, HVAC systems | 0.035-0.045 | Spray or roll application | Check for moisture; replace if wet |

| Fiberglass Insulation | 370 | Buildings, ducts, turbines | 0.04-0.05 | Batt or blanket applications | Check for damage; replace torn sections |

| Silica Aerogel | 650 | Oil & gas, aerospace | 0.013 | Layering and fixing | Minimal maintenance; inspect for cracks |