Leave Your Message

In the ever-evolving landscape of electrical engineering, selecting the appropriate Busbar Insulator is pivotal to ensuring the efficiency and reliability of power distribution systems. According to a recent industry report by Research and Markets, the global busbar market is projected to reach approximately $37 billion by 2025, emphasizing the growing importance of high-quality components, including insulators. As electrical systems become increasingly complex and demand for energy escalates, the role of busbar insulators in safeguarding against electrical discharge and ensuring optimal performance cannot be overstated. This essential guide aims to equip engineers and technical professionals with the insights needed to select the right busbar insulator tailored to their specific electrical needs, thereby contributing to enhanced safety and operational efficiency in their projects.

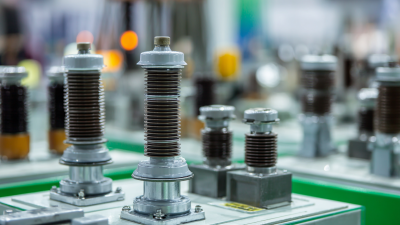

Busbar insulators play a crucial role in electrical systems by providing the necessary support and protection for conductive busbars. These insulators ensure that there is a safe separation between conductive materials, preventing electrical arcing and ensuring the reliability of the overall power distribution system. In various setups, improper insulation can lead to increased risks of short circuits, equipment damage, or even fire hazards, making the selection of the right insulator a fundamental aspect of electrical system design.

When selecting busbar insulators, it's essential to consider factors such as the operating voltage, environmental conditions, and physical dimensions. Different materials exhibit varying levels of dielectric strength and thermal resistance, necessitating a careful evaluation of the operating environment.

Tips: Ensure that you choose insulators made from high-quality materials that can withstand high temperatures and moisture levels. Additionally, always check the manufacturer’s specifications to ensure compatibility with your chosen busbar size and voltage requirements. Investing in the right insulator not only optimizes performance but also enhances the safety and longevity of your electrical system.

When selecting the right busbar insulator for electrical applications, several key factors should be taken into consideration to ensure optimal performance and safety. One of the primary considerations is the electrical insulation properties of the material. According to a report by the International Electrotechnical Commission (IEC), insulators must have a dielectric strength that exceeds the maximum voltage expected in the application to effectively prevent arcing and ensure reliability. Insulators that exhibit high dielectric strength values and good thermal stability are recommended for high-voltage conditions.

Additionally, environmental factors must be assessed, including temperature variations, humidity levels, and potential exposure to corrosive substances. For instance, materials such as silicone and polyester resin are known for their resilience in harsh environments, making them suitable for outdoor applications. The IEC has highlighted that insulators made from these materials can effectively withstand extreme weather conditions, thus prolonging their life cycle and reducing maintenance costs. Furthermore, industry data suggests that choosing an insulator with appropriate mechanical strength can minimize the risk of breakage during installation and in operational settings, thereby enhancing overall system safety.

This chart illustrates key factors influencing the selection of busbar insulators based on various material properties, including electrical strength, thermal stability, and mechanical strength.

When selecting the appropriate busbar insulator, the material used plays a crucial role in ensuring efficiency and safety in electrical distribution. Busbar insulators are typically made from various materials, including ceramic, fiberglass, and polymer. Each material has its own unique properties that can influence the performance based on the application. For instance, ceramic insulators are renowned for their high dielectric strength and thermal stability, making them suitable for high-voltage applications, while polymer insulators offer advantages in weight savings and resistance to environmental factors.

Market research indicates a significant growth in the busbar market, particularly in the Asia-Pacific region, where the market is expected to exceed $8.9 billion by 2024. This surge is primarily driven by rapid industrialization and an increasing demand for efficient and safe power distribution solutions. The anticipated compound annual growth rate (CAGR) of 4.4% from 2025 to 2034 underlines the strengthening need for advanced busbar trunking systems across residential, commercial, and industrial sectors. Furthermore, insights from industry reports suggest that the demand for high-quality insulating materials will continue to rise, with manufacturers focusing on innovative combinations of conductive and insulating materials to meet diverse power rating requirements.

Busbar insulators play a crucial role in various industries, ensuring the safe and efficient operation of electrical systems. Commonly utilized in power generation, transmission, and distribution sectors, these insulators provide essential support to busbars while resisting environmental factors. In industrial applications, such as manufacturing plants and data centers, reliable busbar insulation can help reduce energy losses and improve overall system efficiency.

In transportation, busbar insulators are vital for electrified rail systems and electric buses, where high voltages need to be managed safely. Their ability to withstand extreme weather conditions makes them ideal for outdoor applications, including substations and wind farms. Moreover, the telecommunications industry also benefits from busbar insulators, as they facilitate uninterrupted power supply to critical networks. By understanding the specific requirements of their applications, industries can select the most effective busbar insulators for enhanced performance and safety.

| Application | Industry | Insulator Material | Voltage Rating (kV) | Temperature Range (°C) |

|---|---|---|---|---|

| Power Distribution | Utilities | Silicone | 36 | -40 to 150 |

| Renewable Energy Systems | Solar | Polymer Composite | 15 | -30 to 90 |

| Industrial Automation | Manufacturing | Glass Fiber Reinforced | 20 | -40 to 130 |

| Transportation Infrastructure | Railways | Ceramic | 25 | -50 to 100 |

| High Voltage Substations | Energy | Porcelain | 69 | -60 to 120 |

When it comes to ensuring the longevity of busbar insulators, maintenance and best practices play a crucial role. According to a report from the Institute of Electrical and Electronics Engineers (IEEE), nearly 30% of electrical failures in substations are attributed to inadequate maintenance of insulation systems. Regular inspection is vital; it is recommended that busbar insulators undergo thorough visual inspections at least twice a year while monitoring for signs of erosion, contamination, or physical damage.

Additionally, adherence to industry standards such as those set by the National Electrical Manufacturers Association (NEMA) can significantly contribute to extending the life of busbar insulators. Utilizing the appropriate cleaning methods, like using non-conductive solvents, can prevent the build-up of dirt and grime that often leads to insulation degradation. Furthermore, applying protective coatings can enhance the insulator's resistance to environmental factors, ultimately reducing the risk of premature failure. By following these practices, the operational efficiency and reliability of electrical systems can be significantly improved, supporting a safer and more sustainable energy infrastructure.