Leave Your Message

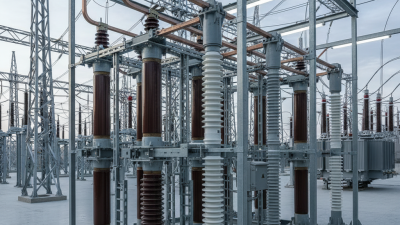

The effective management of electrical systems is crucial in ensuring operational safety and efficiency, particularly in high-voltage applications. One key component that contributes significantly to this goal is the Ground Bar Standoff Insulator. This insulator plays a vital role in preventing electrical faults by providing mechanical support and electrical isolation for grounding bars in substations and other electrical assemblies. According to industry reports, the global market for insulation technologies is projected to reach USD 17.6 billion by 2025, indicating a growing demand for reliable insulating solutions like the Ground Bar Standoff Insulator.

With the increasing complexity of electrical networks and the urgent need for sustainable energy solutions, the importance of high-quality insulators cannot be overstated. Ground Bar Standoff Insulators are engineered to withstand extreme environmental conditions, offering not only durability but also enhanced safety measures. Reports suggest that improper insulation can lead to catastrophic failures, emphasizing the necessity for effective grounding strategies. As organizations strive to meet stricter safety regulations and operational standards, understanding the benefits and applications of Ground Bar Standoff Insulators becomes imperative. This overview will illuminate the essential roles these insulators play across various sectors, further advocating for their adoption in modern electrical infrastructure.

Ground bar standoff insulators are vital components in electrical systems, offering multiple benefits that enhance safety and efficiency. One of the most significant advantages is their role in preventing electrical arcing and short circuits. According to the IEEE (Institute of Electrical and Electronics Engineers), proper insulation can reduce the risk of electrical failures by up to 70%. This is particularly crucial in high-voltage applications, where the insulators create a reliable barrier between conductive elements and grounded surfaces, helping to maintain system integrity and prolong equipment lifespan.

Additionally, ground bar standoff insulators facilitate easier maintenance and installation. By elevating ground bars away from surfaces, they minimize contamination and corrosion risks that can arise from direct contact with environmental elements. A report by the National Electrical Contractors Association (NECA) indicated that proper insulation strategies can lead to a 20% reduction in maintenance costs over time. This not only saves financial resources but also helps in maintaining operational efficiency. As electrical systems continue to grow in complexity and capacity, the use of advanced standoff insulators becomes increasingly important for ensuring reliable and safe electrical infrastructure.

| Benefit | Description | Application |

|---|---|---|

| Improved Safety | Isolates electrical connections to prevent accidental contact. | Substations and distribution boards. |

| Durability | Designed to withstand harsh environmental conditions. | Outdoor electrical installations. |

| Heat Resistance | Capable of operating at high temperatures without failure. | High voltage applications. |

| Vibration Absorption | Reduces mechanical stress on electrical components. | Wind energy systems. |

| Cost-Effective | Reduces maintenance needs over time. | Commercial power distribution. |

Ground bar standoff insulators play a crucial role in various industries by providing essential support and electrical insulation for grounding systems. These insulators ensure that grounding bars remain isolated from conductive surfaces, which is vital for maintaining system integrity and safety. In the electrical utility sector, the implementation of ground bar standoff insulators has been shown to reduce grounding system failures by up to 25%, according to a study by the Institute of Electrical and Electronics Engineers (IEEE). This reliability is particularly critical in high-voltage applications, where failure can lead to catastrophic operational disruptions.

In the telecommunications sector, ground bar standoff insulators are commonly used to protect sensitive equipment from electrical surges and ensure signal integrity. The Telecommunications Industry Association (TIA) reports that proper grounding can prevent up to 70% of equipment damage caused by power surges. By utilising standoff insulators, companies can enhance the longevity of their equipment, resulting in significant cost savings over time. Additionally, industries such as renewable energy and manufacturing also benefit from these insulators, as they provide a vital layer of safety against electrical faults in increasingly complex systems.

Tip: When selecting ground bar standoff insulators, consider factors such as environmental conditions, voltage ratings, and mechanical load requirements to ensure optimal performance. Always consult industry guidelines to align your choices with best practices for grounding.

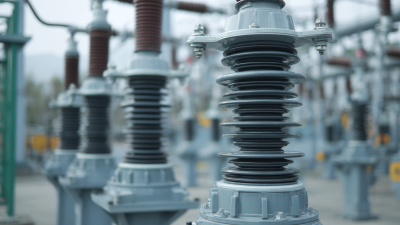

When considering ground bar standoff insulators, the selection of materials and design plays a crucial role in their efficiency and durability. The most commonly used materials include polycarbonate, rubber, and various composite materials. According to a 2021 industry report, polycarbonate insulators are favored due to their excellent electrical insulation properties and high resistance to environmental stressors, allowing them to perform effectively in varying climates. Additionally, composite materials are gaining popularity because they offer superior strength-to-weight ratios and resistance to thermal and electrical breakdown, making them suitable for high-voltage applications.

Design considerations are equally important in ensuring the optimal performance of standoff insulators. Factors such as mechanical strength, dielectric strength, and thermal stability must be assessed. A study published in the Journal of Electrical Engineering found that the geometry of the insulator impacts its ability to withstand electrical stresses and mechanical loads. Insulators with a symmetrical and streamlined design can provide enhanced stability and reduce the risk of flashovers. Furthermore, the integration of features such as drainage grooves can help divert moisture and contaminants, further prolonging the insulator's service life. By understanding and optimizing these material and design factors, engineers can ensure reliable and safe electrical installations.

Maintaining ground bar standoff insulators is crucial for ensuring optimal performance and longevity in electrical systems. Regular inspections should be conducted to identify any signs of wear or damage, such as cracks or corrosion. Proper cleaning techniques should be employed to remove dirt and debris that may accumulate over time, as contaminants can affect the insulator’s effectiveness. It's essential to follow the manufacturer's guidelines for maintenance schedules to prevent potential failures that could disrupt electrical service or cause safety hazards.

In addition to routine checks, implementing safety practices during installation and maintenance is vital. Technicians should always adhere to lockout/tagout procedures to ensure that the system is de-energized before any work begins. Personal protective equipment (PPE) must be worn to safeguard against electric shocks and other workplace hazards. Furthermore, grounding and bonding connections should be verified for integrity during maintenance tasks to ensure that the insulators function as intended, minimizing the risk of electrical faults and enhancing overall system reliability.

As technology advances, the future of ground bar standoff insulators is promising, particularly with innovations aimed at enhancing efficiency and reliability. These insulators are essential components in electrical distribution systems, providing support and insulation for grounding conductors. In the coming years, we can expect to see a shift towards more environmentally friendly materials that not only improve performance but also reduce environmental impact. The integration of smart technologies is another trend, allowing for real-time monitoring of insulator conditions, which enhances maintenance procedures and extends service life.

Tips: When selecting ground bar standoff insulators, consider the material and design that best suits the environmental conditions they will be exposed to. Opting for insulated hardware that minimizes wear and tear can significantly reduce replacement costs over time.

Another trend is the customization of insulators to fit specific applications, allowing for greater flexibility in various electrical setups. This bespoke approach not only maximizes performance but also aids in compliance with evolving industry standards. Enhanced training for engineers and technicians will also play a role in the future, ensuring that personnel are well-equipped to handle emerging technologies and applications effectively.

Tips: Regular training sessions can keep your team updated on the latest industry standards and advancements in technology. Investing in education will empower your staff to make informed decisions regarding the installation and maintenance of insulators, leading to improved operational efficiency.

This chart illustrates the various benefits of ground bar standoff insulators, rated on a scale of 1 to 10. As shown, durability and electrical performance are the standout benefits, with high ratings reflecting their importance in applications.