Leave Your Message

As the demand for reliable electrical safety solutions continues to grow, the role of

Low Voltage Standoff Insulators has become increasingly critical in

safeguarding both electrical systems and personnel. According to the National Electrical Manufacturers Association (NEMA), the adoption of innovative insulating technologies is projected to increase by over

25% by 2025, driven by the urgent need to comply with stringent safety regulations and to enhance the durability of electrical infrastructures.

Low Voltage Standoff Insulators, which provide essential separation between conductive parts and grounding surfaces, are at the forefront of this evolution. By exploring alternative options within this technology sector, we can identify innovative materials and designs that not only maximize safety but also optimize operational efficiency, paving the way for a safer and more reliable electrical future.

Low Voltage Standoff Insulators, which provide essential separation between conductive parts and grounding surfaces, are at the forefront of this evolution. By exploring alternative options within this technology sector, we can identify innovative materials and designs that not only maximize safety but also optimize operational efficiency, paving the way for a safer and more reliable electrical future.

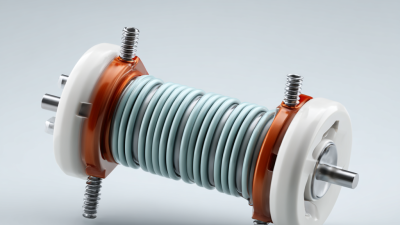

Innovative designs in low voltage standoff insulators are setting a new standard in the realm of electrical safety. Traditionally, insulators have focused primarily on their ability to isolate electrical currents, but the latest advancements emphasize user safety and reliability. These new designs incorporate advanced materials that enhance durability while maintaining lightweight features, allowing for easier installation and maintenance. With improved resistance to environmental factors such as moisture and corrosion, these insulators ensure that electrical systems operate smoothly without compromising safety.

Moreover, innovative configurations of standoff insulators are being developed to reduce the risk of accidental contact with live wires. By incorporating protective barriers and ergonomic shapes, these designs not only safeguard personnel but also minimize the chances of equipment damage. Additionally, the use of color coding and standardized markings enhances visibility, which is critical in high-risk environments. As the industry evolves, these advancements are revolutionizing how low voltage systems are approached, creating safer operational conditions and fostering greater confidence in electrical infrastructure.

Modern low voltage standoff insulators are transforming the landscape of electrical safety with their advanced features. These insulators not only provide electrical isolation but also ensure enhanced durability and resistance to environmental conditions. Made from composite materials, they withstand extreme temperatures, UV exposure, and moisture, thus extending their service life and reliability. Their design incorporates a high dielectric strength, significantly reducing the risk of electrical arcs, making them essential for various applications in power distribution systems.

Tip: When selecting standoff insulators, always consider the specific environmental conditions they will be exposed to. This will ensure that you choose the right materials that offer optimal performance and longevity.

Moreover, the ergonomic design of modern standoff insulators facilitates easier installation and maintenance. With their lightweight yet robust construction, these insulators can be installed with minimal effort, reducing labor costs and time. Additionally, integrated features such as visual indicators for wear and damage help in regular monitoring, ensuring timely interventions before potential failures occur.

Tip: Regular inspections of standoff insulators can prevent significant downtime and maintenance costs, ensuring the safety and efficiency of electrical systems.

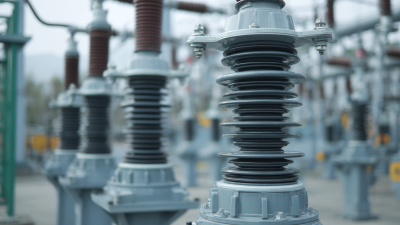

Low voltage standoff insulators are playing a critical role in enhancing

electrical safety

across various real-world applications. These innovative components are designed to provide

electrical insulation while maintaining structural integrity in environments where space is at a premium.

Industries such as telecommunications and renewable energy are integrating these insulators into

their infrastructure to minimize the risk of electrical faults and improve the longevity of their systems.

This transformation is particularly important in urban settings, where the proximity of power lines to

buildings can create hazards that low voltage standoff insulators can effectively mitigate.

In the realm of renewable energy, low voltage standoff insulators are

essential for solar panel installations

and wind energy systems. By ensuring effective insulation and spacing between conductive parts,

they help optimize the performance of these systems while safeguarding against lightning strikes

and other environmental factors. Their lightweight design and ease of installation also facilitate

a faster turnaround in project deployment, ultimately making renewable energy sources more accessible

and efficient. As the demand for safe and sustainable electrical installations continues to grow,

low voltage standoff insulators are proving to be

indispensable in the evolution of electrical safety standards.

In the realm of renewable energy, low voltage standoff insulators are

essential for solar panel installations

and wind energy systems. By ensuring effective insulation and spacing between conductive parts,

they help optimize the performance of these systems while safeguarding against lightning strikes

and other environmental factors. Their lightweight design and ease of installation also facilitate

a faster turnaround in project deployment, ultimately making renewable energy sources more accessible

and efficient. As the demand for safe and sustainable electrical installations continues to grow,

low voltage standoff insulators are proving to be

indispensable in the evolution of electrical safety standards.

The landscape of electrical safety is evolving dramatically with the advent of advanced low voltage standoff insulators. Traditionally, insulators have relied on ceramic and glass materials, which, while effective, often present challenges related to weight, durability, and susceptibility to environmental conditions. According to the IEEE, the failure rates of traditional insulators can reach up to 20% under severe weather conditions, leading to increased maintenance costs and potential disruptions in service stability.

In contrast, modern insulator technologies, such as composite and polymer-based materials, demonstrate enhanced performance. Recent industry reports indicate that these advanced insulators can reduce failure rates by more than 50% compared to their traditional counterparts. For example, engineering assessments by the Electric Power Research Institute (EPRI) have shown that polymer insulators possess superior hydrophobic properties, significantly decreasing pollution-related flashover incidents.

As infrastructure demands continue to rise, embracing innovation in insulator design not only ensures greater reliability but also promotes sustainable energy solutions, meeting both safety and environmental standards in the ever-evolving electrical landscape.

The evolution of low voltage standoff insulators is poised to significantly enhance electrical safety standards as the industry adapts to emerging technologies and trends. As electric vehicles (EVs) increasingly dominate the transportation landscape, the demand for reliable electrical infrastructure is surging. Recent studies indicate that the global electric vehicle charging station infrastructure must expand by over 30% annually to accommodate the projected growth in zero and ultra-low emission vehicles. This rapid expansion calls for improved electrical safety measures, making advanced low voltage standoff insulators essential for minimizing risks associated with electrical hazards.

Moreover, the increasing complexity of automotive electrical systems highlights the necessity for robust insulation materials. Analysis of automotive electrical harnesses reveals that they contain hundreds of wires and components, underscoring the importance of dielectric integrity. The trend towards smart grids and renewable energy integration affects low voltage insulators, as reliability in electrical insulation becomes a critical factor in ensuring grid stability and safety. Consequently, the future of low voltage standoff insulators will be tightly intertwined with the ongoing advancements in electrical safety standards, paving the way for safer and more efficient energy systems across various sectors.

| Feature | Current Standard | Future Trend | Safety Impact |

|---|---|---|---|

| Material Composition | PVC/Polymer | Composite Materials | Higher durability and fire resistance |

| Insulation Level | Low to Moderate | High Insulation Ratings | Reduced risk of electric shock |

| Design Flexibility | Rigid Structures | Modular Designs | Easier installation and maintenance |

| Environmental Resistance | Limited to Standard Conditions | Enhanced Weatherproofing | Increased lifespan and reliability |

| Compliance Standards | National Standards | Global Standards | Uniform safety protocols worldwide |