Leave Your Message

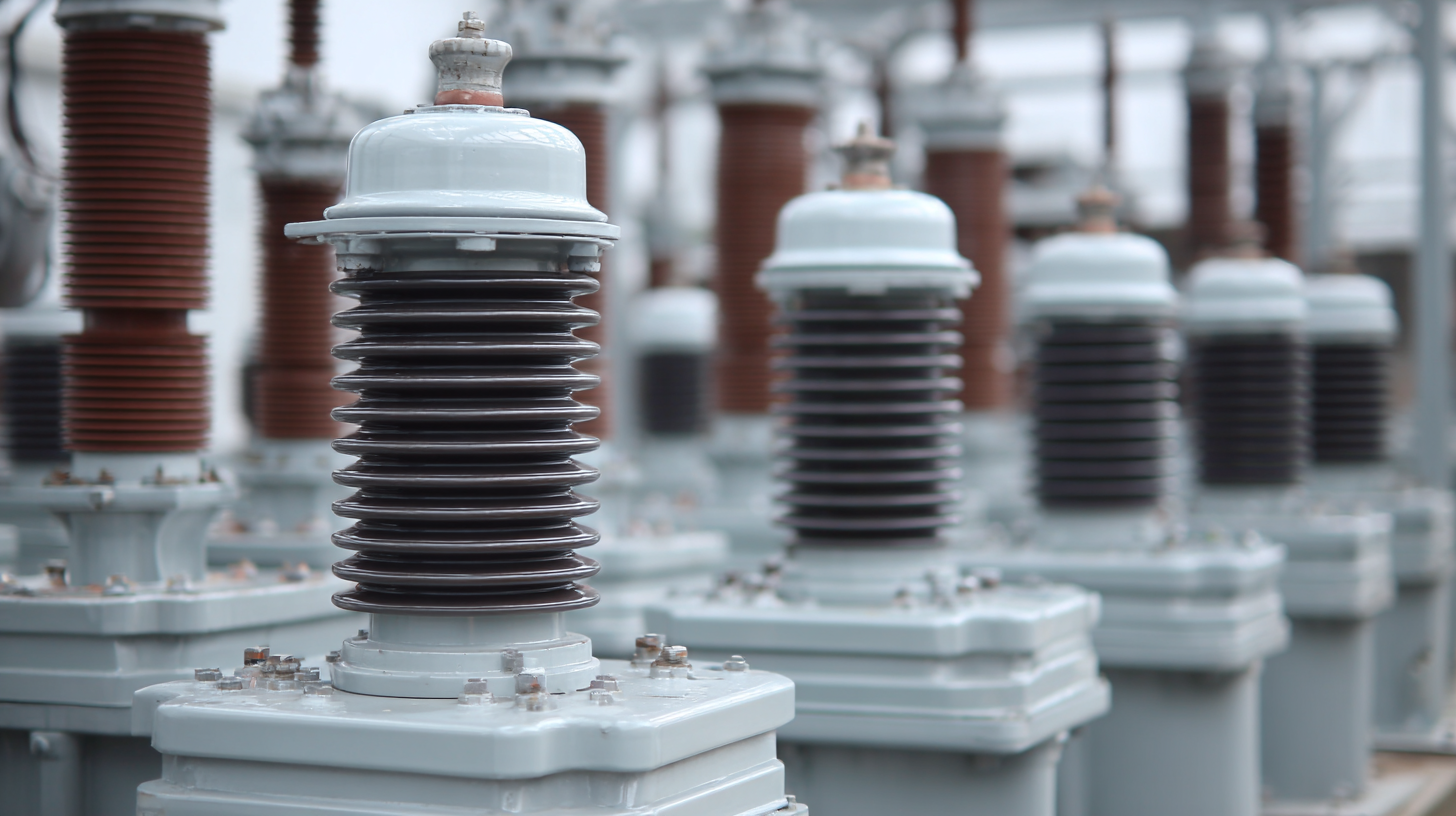

As the global energy landscape evolves towards sustainability, the role of innovative materials in electrical infrastructure becomes increasingly vital. Composite insulators, which are recognized for their superior resistance to environmental stresses and reduced weight compared to traditional porcelain insulators, are gaining traction among Composite Insulator Suppliers. According to a recent industry report by MarketsandMarkets, the global composite insulator market is projected to grow from USD 1.3 billion in 2020 to USD 2.5 billion by 2025, at a CAGR of 14.7%. This surge in demand highlights the growing acknowledgment of composite insulators as crucial components in modernizing power grids while meeting sustainability goals. With technological advancements paving the way for enhanced performance, the future of composite insulators promises to redefine the standards for reliability and environmental responsibility in the electrical sector.

The advancement of composite insulators is pivotal for high-voltage applications, yet several challenges persist within the current technology. A recent market analysis predicts substantial growth in the composite insulators sector, driven by increasing demand for high-efficiency components and improvements in material science. Specifically, the composite insulator market is forecasted to expand significantly from 2025 to 2034, emphasizing the need for innovation that balances performance and sustainability.

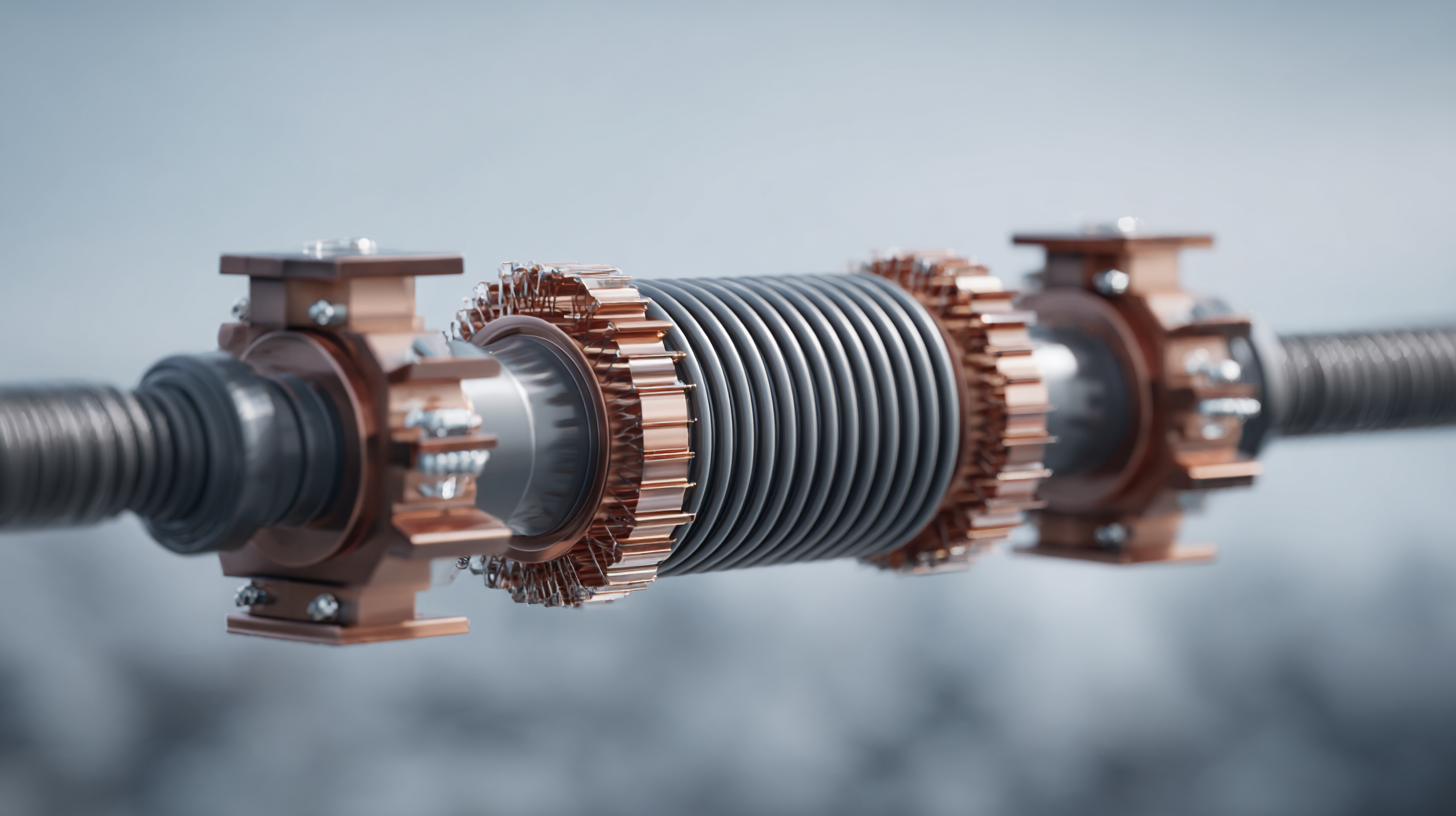

One of the pressing challenges highlighted in recent reviews is the efficiency of production techniques and their environmental impact. The adoption of technologies such as filament winding demonstrates potential in enhancing the manufacturing processes of composite pressure vessels, but similar innovations are needed for insulators to optimize scalability and reduce costs. Additionally, emerging solutions like the environmentally-friendly pyrolysis method for recycling waste insulator materials reveal a path towards sustainability, showcasing the industry's dual focus on performance enhancement and ecological responsibility. Efficient monitoring techniques, such as those utilizing advanced image processing algorithms, are also vital to ensure the reliability of insulations under various conditions, thereby addressing some current operational challenges.

The environmental impact of composite insulators in electrical applications is increasingly significant as the world seeks more sustainable energy solutions. Composite insulators, made from materials such as fiberglass and polymer, offer a lighter and more durable alternative to traditional ceramic or glass insulators. This shift not only improves the efficiency of energy transmission but also reduces the physical footprint of utility infrastructure, minimizing land disturbance and habitat disruption.

Moreover, the production and disposal processes for composite materials are evolving to address ecological concerns. Innovative recycling techniques are being developed to repurpose spent insulators, thereby minimizing waste and promoting a circular economy. Additionally, because composite insulators exhibit superior resistance to environmental degradation, they often have a longer lifespan than their traditional counterparts, which results in reduced maintenance and replacement costs. This resilience translates into fewer resources consumed over time, making composite insulators a more environmentally-friendly choice in the pursuit of sustainable electrical applications.

As the demand for reliable and sustainable electrical infrastructure increases, innovation in composite insulators has never been more crucial. Recent trends are focusing on enhancing the durability and performance of these insulators through advanced materials and manufacturing techniques.

Today, industry leaders are exploring new polymer blends that not only improve electrical insulation properties but also offer resistance to environmental degradation. This shift towards high-performance materials ensures that insulators can withstand extreme weather conditions and extend their operational life.

Tip: When selecting composite insulators, consider the specific environmental conditions of your application. Insulators tailored for high UV exposure or prolonged wet conditions can significantly reduce maintenance costs and failure rates.

Moreover, the integration of smart technologies is shaping the future of composite insulators. Innovations such as sensors embedded within insulators allow for real-time monitoring of performance metrics. This proactive approach facilitates timely maintenance and enhances overall system reliability, protecting investment and ensuring continuous service.

Tip: Implementing a smart monitoring system can lead to better operational insights and timely intervention, effectively minimizing downtime and improving efficiency in electrical networks.

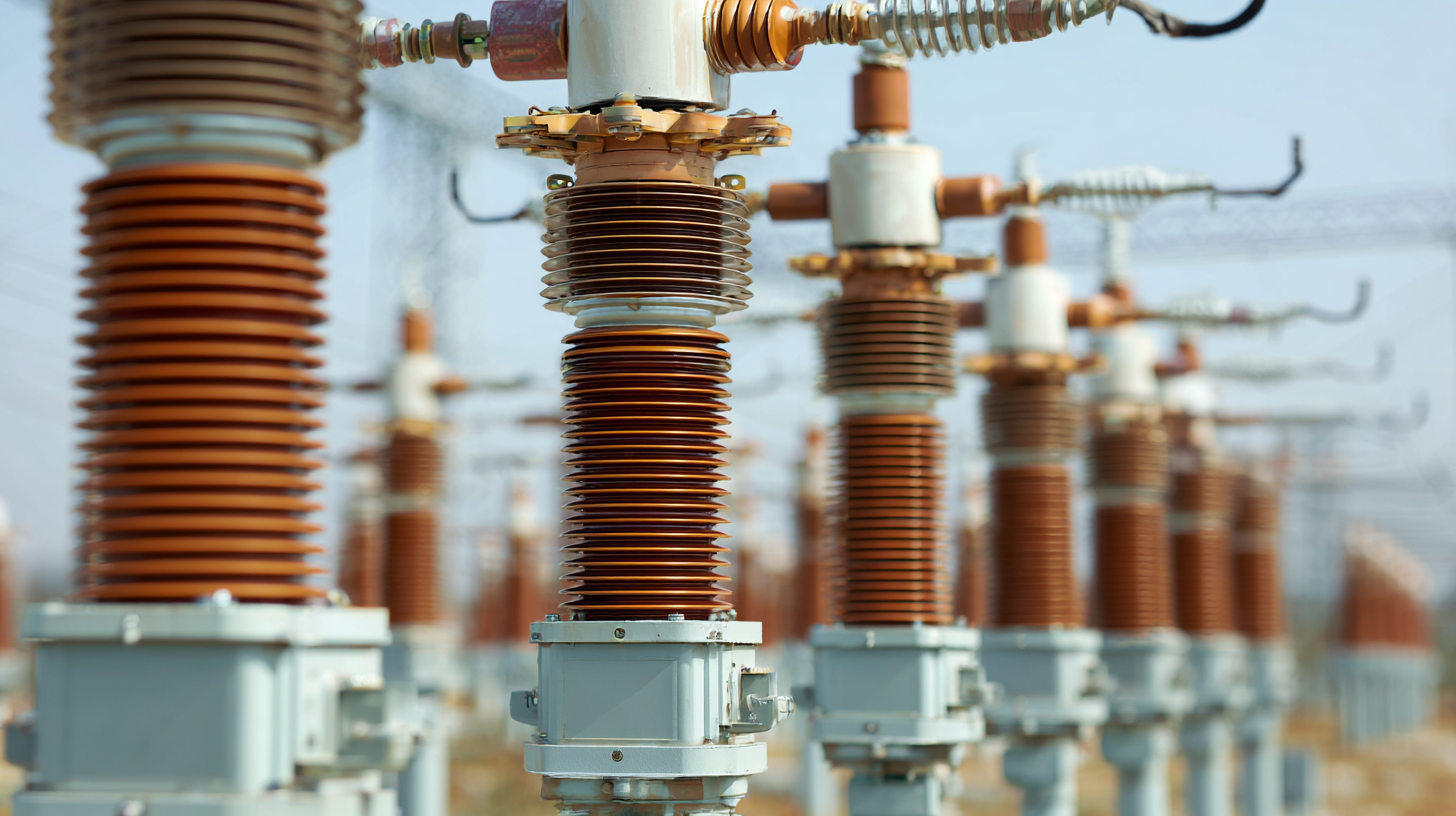

The manufacturing of composite insulators is undergoing a significant transformation, driven by a growing emphasis on sustainability. As the demand for more environmentally friendly products increases, manufacturers are adopting practices that reduce waste and lower energy consumption. Advanced materials and production techniques have emerged that not only enhance the performance of the insulators but also minimize their ecological footprint. Utilizing recyclable materials and implementing closed-loop systems are integral to this shift, allowing for the reuse of resources and reducing reliance on virgin materials.

In addition to material selection, companies are exploring renewable energy sources for their manufacturing processes. By harnessing solar or wind energy, manufacturers can dramatically cut down their carbon emissions, further aligning with sustainable development goals. Additionally, conducting life cycle assessments enables businesses to identify areas for improvement, ensuring that every stage of the product’s life—from production to disposal—is environmentally conscientious. As the industry moves forward, innovations aimed at sustainability will undoubtedly shape the future of composite insulators, making them not only superior in performance but also responsible choices for a greener planet.

The field of composite insulators is witnessing rapid advancements driven by both innovation and sustainability. Future directions in research and development are focusing on enhancing the performance of these insulators through novel materials and designs. Researchers are exploring the incorporation of nanotechnology to improve the mechanical strength and hydrophobic properties of composite materials. This not only increases their durability but also enhances their ability to withstand severe environmental conditions, making them ideal for both urban and rural electrical applications.

In addition to performance enhancements, sustainability is a critical theme in the development of composite insulators. Efforts are being made to reduce the carbon footprint of manufacturing processes and to use recyclable materials in production. Ethical sourcing of raw materials is also being emphasized, with researchers looking into bio-based composites as alternatives to traditional petroleum-based formulations. As the demand for reliable and environmentally friendly electrical infrastructure grows, these innovative strategies in composite insulator solutions will pave the way for a more sustainable future in the energy sector.

| Dimension | Current Value | Future Target | Sustainability Impact | Innovative Solution |

|---|---|---|---|---|

| Weight Reduction | 10 kg | 7 kg | Decreased transportation emissions | Lightweight composite materials |

| Electrical Strength | 70 kV | 85 kV | Enhanced grid reliability | Modified polymer composites |

| Lifecycle Duration | 20 years | 30 years | Reduced waste in landfills | Durable composite formulations |

| Cost Efficiency | $300/unit | $250/unit | Lower cost of energy transmission | Advanced manufacturing processes |

| Environmental Compatibility | Moderate | High | Reduction in harmful emissions | Bio-based composite materials |