Leave Your Message

When selecting the right Medium Voltage Post Insulator, various factors come into play that can significantly influence the efficiency and reliability of electrical systems. Experts in the field emphasize the importance of understanding both the technical specifications and the environmental conditions that these insulators will face. Dr. Emily Reynolds, a leading authority in electrical engineering, states, “The choice of a Medium Voltage Post Insulator can determine the lifespan and safety of an entire electrical network.” This insight highlights the critical nature of making informed decisions in the selection process.

The role of Medium Voltage Post Insulators extends beyond merely serving as a support structure; they are integral to maintaining the insulation and protection of electrical systems against environmental stresses and electrical breakdowns. Factors such as material composition, mechanical strength, and dielectric properties must be thoroughly evaluated. Additionally, the insulators’ performance in various climatic conditions can greatly affect their overall effectiveness and reliability in long-term operations.

As advancements in materials and technology evolve, understanding these top considerations becomes even more crucial for engineers and decision-makers alike. The right Medium Voltage Post Insulator not only enhances operational efficiency but also contributes to safety and longevity in electrical distribution networks.

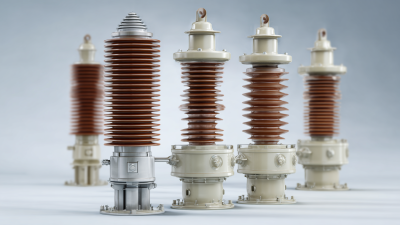

Medium voltage post insulators are crucial components in electrical systems, ensuring reliable operation and safety. These insulators support overhead lines and help maintain electrical isolation, which is essential for reducing the risk of short circuits and other electrical hazards. Understanding their structure, material, and application is vital for selecting the right insulator for your needs.

When choosing medium voltage post insulators, consider the environmental conditions in which they will operate. Factors such as humidity, pollution, and temperature can significantly affect the performance and longevity of the insulators. For example, silicone rubber insulators may perform better in harsh weather than traditional ceramic options.

**Tip:** Always assess the ambient conditions and select materials designed to withstand the expected environmental challenges.

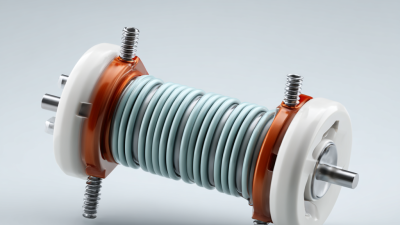

Additionally, mechanical strength should be a priority. Post insulators must be robust enough to endure physical stresses, including wind, ice accumulation, and vibrations from nearby equipment. It is beneficial to review the mechanical ratings and testing standards the insulators have undergone to ensure they meet the demands of your specific application.

**Tip:** Consult with industry experts to understand which mechanical specifications are essential for your particular installation.

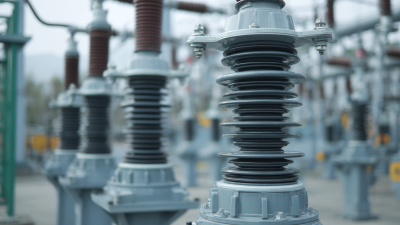

Medium voltage post insulators play a crucial role in the stability and reliability of power distribution systems. These insulators are essential components that prevent electrical leakage and ensure that electricity is efficiently transmitted over long distances. One of their key functions is to support the overhead power lines while maintaining adequate electrical insulation. This capability not only prevents short circuits but also protects personnel and equipment from potential hazards associated with high voltage electricity.

Additionally, the importance of medium voltage post insulators extends beyond mere electrical insulation. They are designed to withstand environmental factors such as temperature fluctuations, humidity, and pollution, which can significantly affect their performance. The selection of suitable materials and designs enhances durability and longevity, ensuring continuous operation in diverse conditions. By providing reliable insulation, these components help in minimizing outages and improving the overall efficiency of power distribution, thereby contributing to a stable and robust energy infrastructure.

When selecting medium voltage post insulators, material selection plays a critical role in ensuring both durability and performance under various environmental conditions. Common materials include porcelain, glass, and polymer composites. Porcelain insulators are known for their outstanding mechanical strength and resistance to UV radiation. They perform exceptionally well in harsh weather environments but can be susceptible to cracking under extreme thermal cycling. Glass insulators offer excellent electrical properties and are not prone to degradation from UV exposure or moisture absorption. However, their weight and fragility can pose challenges during installation and maintenance.

On the other hand, polymer composite insulators, made from a combination of organic and inorganic materials, are gaining popularity due to their lightweight nature and superior resistance to pollution and corrosion. These insulators can endure adverse weather conditions, making them suitable for applications in coastal or industrial environments. The flexibility of polymer materials also allows for innovative design and enhanced performance under specific operational conditions. Ultimately, the choice of material should align with the specific requirements of the installation, considering factors like environmental conditions, mechanical stresses, and electrical performance.

| Factor | Material Options | Durability | Performance | Cost |

|---|---|---|---|---|

| Electrical Properties | Porcelain, Composite, Glass | Excellent (Porcelain) Good (Composite) Moderate (Glass) |

High Voltage Insulation | Medium |

| Mechanical Strength | Composite, Porcelain | High (Composite) Moderate (Porcelain) |

Good Under Stress | High (Composite) |

| Weather Resistance | Composite, Porcelain | Excellent (Composite) Good (Porcelain) |

High UV Resistance | Medium |

| Installation Feasibility | Composite | Easy Handling | Quick Setup | Lower |

| Thermal Stability | Porcelain, Glass | High Stability (Porcelain) Moderate (Glass) |

Good Performance in Heat | Medium to High |

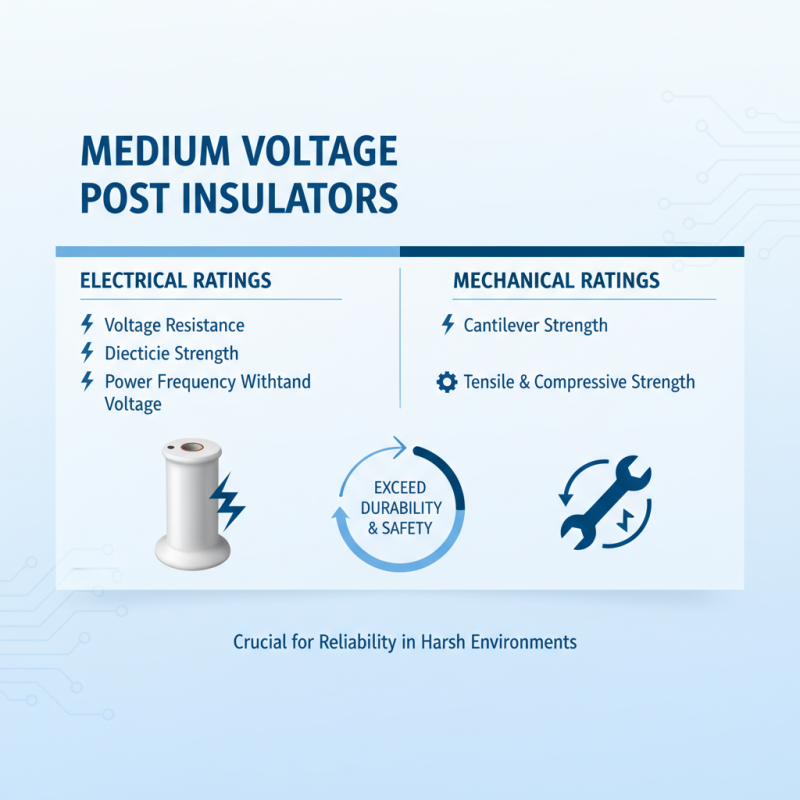

When selecting medium voltage post insulators, understanding their electrical and mechanical ratings is crucial. Electrical ratings primarily include voltage resistance, dielectric strength, and power frequency withstand voltage. These parameters ensure that the insulator can handle the specific voltage levels without breaking down. It's essential to choose insulators that not only meet but exceed the required electrical specifications for your particular application, especially in environments where surges or transients might occur.

Mechanical ratings are equally important, as they determine the structural integrity and durability of the insulators under physical stress. Parameters such as mechanical strength, impact resistance, and environmental conditions (like temperature variations and corrosive elements) should be evaluated. A robust insulator must withstand not only its typical load but also unexpected forces like wind or seismic activity.

**Tips**:

- Always consult with engineering standards and guidelines to ensure compliance with safety measures.

- Consider the specific environmental conditions of the installation site, as this can significantly affect both electrical and mechanical performance.

- When in doubt, consult with a specialist to analyze the requirements, as they can provide insights tailored to your specific needs.

When selecting medium voltage post insulators, environmental considerations play a pivotal role in ensuring both functionality and sustainability. Factors such as temperature fluctuations, humidity levels, and exposure to pollutants can significantly impact the performance and lifespan of insulators. Materials used in manufacturing these insulators should be resilient against chemical degradation and should not leach harmful substances into the surrounding environment. Choosing insulators that comply with stringent environmental regulations not only contributes to ecological preservation but also minimizes the risks associated with material failure and increased maintenance costs.

Longevity is another crucial element, closely intertwined with environmental factors. Insulators that demonstrate excellent resistance to aging and wear will perform reliably over time. Attention should be paid to the dielectric properties and mechanical strength of the materials, as these characteristics dictate how well the insulator can withstand environmental stressors such as UV radiation and extreme weather conditions. Furthermore, advancements in technology have led to the development of composite materials that offer enhanced durability, reducing the frequency of replacements and promoting cost-effectiveness in the long term. As the demand for sustainable and reliable infrastructure grows, prioritizing both environmental and longevity considerations in the selection of medium voltage post insulators is essential for robust electrical systems.