Leave Your Message

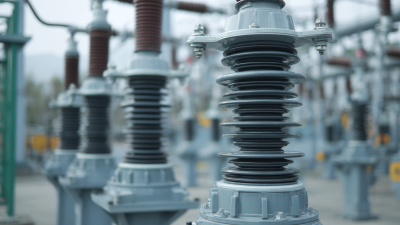

Choosing the right Medium Voltage Insulator is crucial for ensuring the reliability and safety of electrical distribution systems. As electricity demand continues to rise globally, the importance of effective insulation in medium voltage applications cannot be overstated. According to a recent report by the International Electrotechnical Commission (IEC), proper insulator selection can enhance system performance and decrease maintenance costs by up to 30% over the lifespan of the equipment. This highlights the necessity for engineers and project managers to make informed decisions when it comes to insulator materials, types, and dimensions.

Industry expert Dr. Jane Smith, a leading authority in electrical engineering, emphasizes, "The selection of Medium Voltage Insulators directly impacts the operational efficiency and longevity of power systems." Her insights reflect the growing recognition within the sector that choosing the appropriate insulator involves not only technical specifications but also considerations of environmental conditions and project-specific requirements. By taking these factors into account, professionals can enhance the integrity of their electrical infrastructure, ensuring optimal performance and reduced risk of failure. This article aims to provide essential tips for selecting the right Medium Voltage Insulator, helping professionals navigate the complexities of their choices in a dynamic and evolving industry.

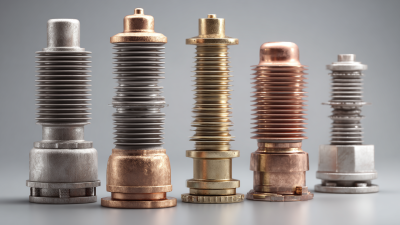

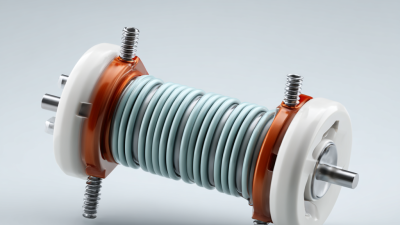

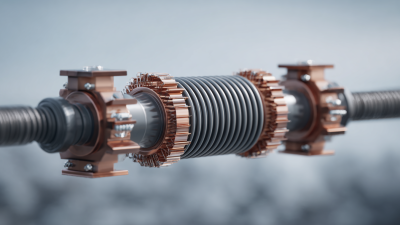

Medium voltage insulators play a crucial role in the effective and safe operation of electrical systems, particularly in varied applications such as power distribution and transmission lines. Primarily, there are a few types of medium voltage insulators, each serving different purposes based on their material composition and design. Ceramic insulators, known for their durability and excellent electrical properties, are commonly used in outdoor applications, where they can withstand harsh weather conditions. Conversely, composite insulators, made from polymer or fiberglass, are gaining popularity due to their lightweight nature and resistance to environmental degradation, making them suitable for both overhead lines and substations.

Moreover, the selection of appropriate medium voltage insulators often depends on the specific application and environmental conditions. For instance, pin-type insulators are effective for vertical installations on poles, while strain insulators are ideal for tension applications in transmission lines. Another noteworthy option is the suspension insulator, which is typically used to support the weight of conductors in overhead lines. Understanding the variations among these insulators and their respective applications is vital for ensuring optimal performance, longevity, and safety in any electrical system.

By evaluating the conditions in which these insulators will operate, engineers can select the most suitable type, thus enhancing the reliability and efficiency of medium voltage networks.

When selecting medium voltage insulators, it is crucial to consider several key factors that influence both performance and longevity. One of the primary considerations is the electrical strength required for the specific application. According to a report by the International Electrotechnical Commission (IEC), medium voltage insulators must withstand a minimum dielectric strength of 20 kV/mm to ensure reliability in environments with high voltage fluctuations. Additionally, the operational environment—whether it be coastal, industrial, or rural—plays a significant role in material selection. Insulators in coastal areas, for example, should have enhanced resistance to pollution and moisture, as outlined by IEEE standards.

Another critical factor is the mechanical strength of the insulators. Data from the National Electrical Manufacturers Association (NEMA) indicates that insulators must endure various mechanical stresses, particularly in regions with a high likelihood of severe weather events, such as ice storms or high winds. Selecting materials with the correct tensile strength and impact resistance is essential to minimize the risk of failures that could lead to service interruptions or safety hazards. Moreover, it's important to evaluate the long-term reliability of the materials used, as lifecycle durability can significantly impact maintenance costs and operational efficiency over time. Ensuring that the chosen insulator meets or exceeds industry standards is vital for safe and effective performance in demanding applications.

When selecting medium voltage insulators, understanding the material properties is crucial as they directly impact performance and longevity. Insulators are subjected to various environmental conditions, including temperature variations, humidity, and pollution levels. According to the International Electrotechnical Commission (IEC), ceramic and polymer insulators are two of the most commonly used materials in medium voltage applications. Ceramic insulators, made from high-strength alumina, offer exceptional dielectric strength, typically exceeding 20 kV/mm. Their ability to withstand mechanical stress and resistance to weathering makes them a reliable choice for many utility applications.

On the other hand, polymer insulators, which are often made from materials such as silicone rubber, are gaining popularity due to their lightweight properties and flexibility. They usually present a dielectric strength that ranges from 20 to 30 kV/mm, allowing for effective insulation even under harsh conditions. A report published by the American National Standards Institute (ANSI) highlights that polymer insulators exhibit lower maintenance costs and higher resistance to contamination compared to traditional materials. Understanding the specific advantages of each material will help engineers and utility managers select the right insulator for their medium voltage applications, ultimately enhancing the reliability and safety of electrical infrastructure.

| Insulator Type | Material | Dielectric Strength (kV/mm) | Thermal Stability (°C) | Mechanical Strength (MPa) | Environmental Resistance |

|---|---|---|---|---|---|

| Porcelain | Ceramic | 20-25 | 150-250 | 50-70 | High |

| Glass | Silica based | 30-35 | 200-300 | 60-80 | Very High |

| Composite | Polymer | 15-20 | 100-150 | 40-60 | Moderate |

| Silicone | Silicone Rubber | 25-30 | 180-220 | 35-50 | High |

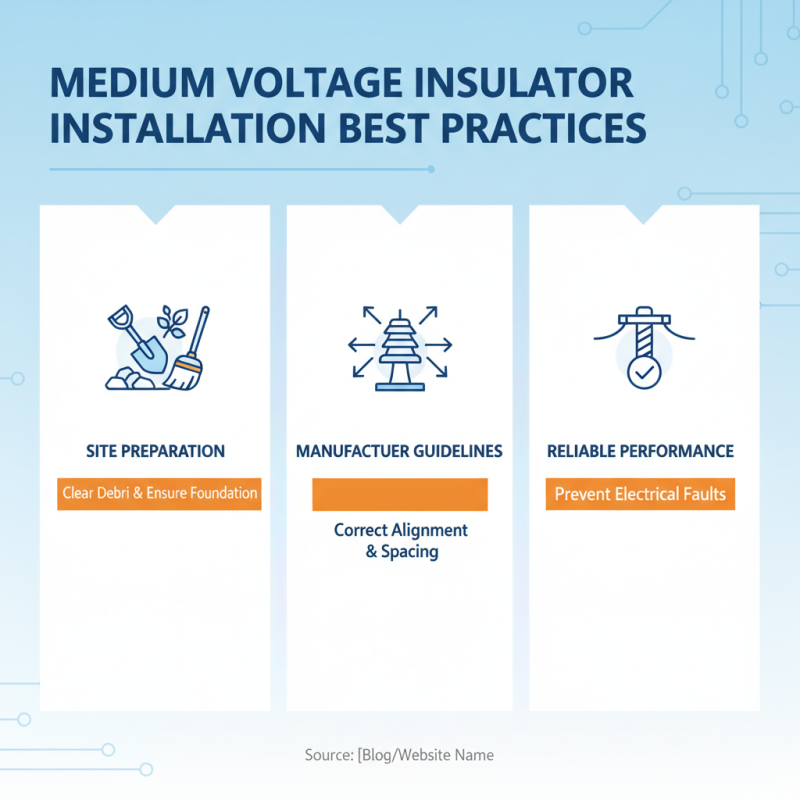

When it comes to installing medium voltage insulators, following best practices is crucial to ensure reliable performance and longevity. First and foremost, proper site preparation is essential. This includes clearing the area of debris and ensuring that the foundation can adequately support the insulator’s design specifications. Additionally, make sure to install insulators in accordance with the manufacturer’s guidelines, ensuring alignment and spacing are correct to prevent electrical faults.

Tips for maintaining insulators include regular inspections for physical damage and wear. It is vital to check for signs of contamination, such as dirt or salt deposits, which can compromise their integrity. Cleaning should be done with appropriate methods and materials to avoid damaging the insulator. Furthermore, conduct periodic electrical testing to assess the insulator's performance under operational conditions. Keeping detailed maintenance records can also help identify potential issues early and schedule necessary repairs promptly.

Lastly, ensuring proper environmental considerations during installation and maintenance can prolong the life of your insulators. Factors such as temperature fluctuations, humidity, and pollution levels should be assessed to select the most suitable insulator type and maintenance schedule. This proactive approach will enhance the reliability and safety of your medium voltage systems, minimizing unexpected outages.

When selecting medium voltage insulators, it is crucial to avoid common pitfalls that could lead to inefficient performance or safety hazards. One of the most frequent mistakes is neglecting to consider environmental factors, such as pollution levels and climatic conditions. Insulators must be suitable for their operating environment; for example, areas with high pollution may require insulators with better contamination resistance to prevent premature failure.

Another common error is underestimating the importance of electrical and mechanical strength ratings. Choosing an insulator without adequate strength can result in catastrophic failures under operational stress. It’s essential to analyze load requirements thoroughly and select insulators that not only meet but exceed these demands. Additionally, failing to consult relevant standards and guidelines can lead to improper selection, as the right specifications vary by application and geographic region.

Lastly, overlooking the maintenance and installation processes can lead to operational issues down the line. Potential buyers should consider the ease of installation and accessibility for maintenance to ensure long-lasting performance. By being aware of these common mistakes, professionals can make informed decisions that enhance the reliability and safety of their medium voltage systems.