Leave Your Message

In the ever-evolving field of electrical engineering, selecting the appropriate Electrical Conductor Insulator is pivotal for ensuring optimal performance and safety in electrical systems. According to industry reports, the global demand for electrical insulation materials is projected to reach $74 billion by 2026, growing at a CAGR of 5.2% from 2021 to 2026. This increase underscores the critical role that high-quality insulators play in enhancing the efficiency and longevity of electrical conductors across various applications, including power transmission and renewable energy systems. As technology progresses, the variety of available insulator materials, such as polyimide and silicone-based alternatives, complicates the selection process. Therefore, understanding key factors—including thermal stability, dielectric strength, and environmental impact—becomes essential in making informed decisions that align with industry best practices.

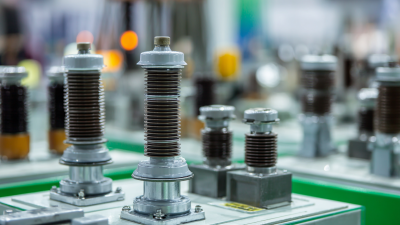

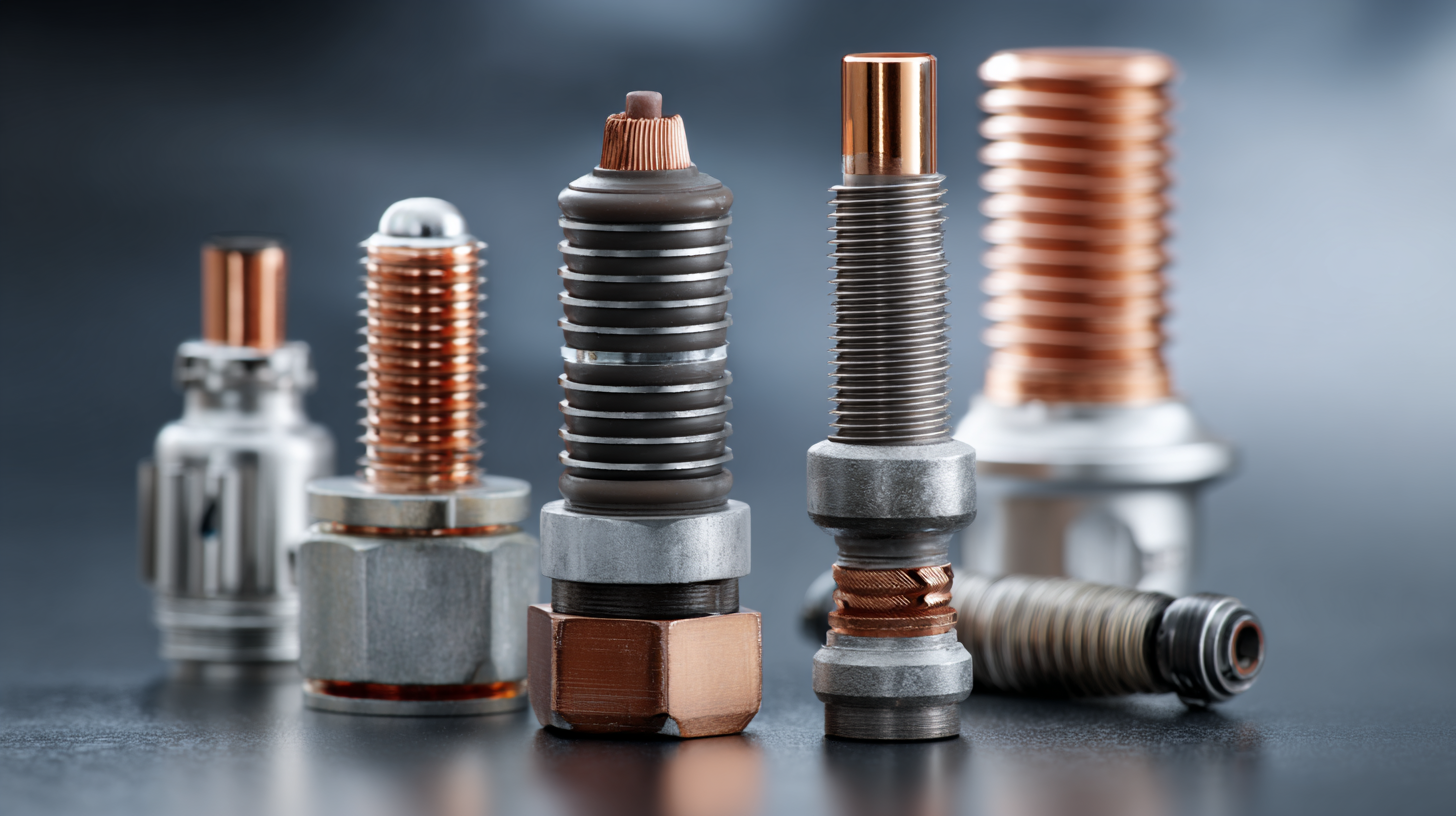

When selecting the right electrical conductor insulator, it's crucial first to understand the various types of electrical conductors and insulators available on the market. Conductors, typically made from materials such as copper and aluminum, are designed to facilitate the passage of electrical current. Each conductor type possesses distinct characteristics that influence its conductivity, resistance to corrosion, and temperature tolerance. For example, copper, while more expensive, offers superior conductivity and is less prone to rust compared to aluminum, making it a popular choice in high-performance applications.

On the other hand, electrical insulators serve to prevent unwanted current flow and protect against electric shock. Common insulating materials include rubber, glass, and various polymers, each with unique properties. Rubber, for instance, provides flexibility and excellent thermal resistance, making it suitable for a range of environments, while glass offers high dielectric strength, making it ideal for high-voltage applications. Understanding the specific application requirements can help users select the appropriate combination of conductors and insulators to optimize safety and performance in their electrical systems.

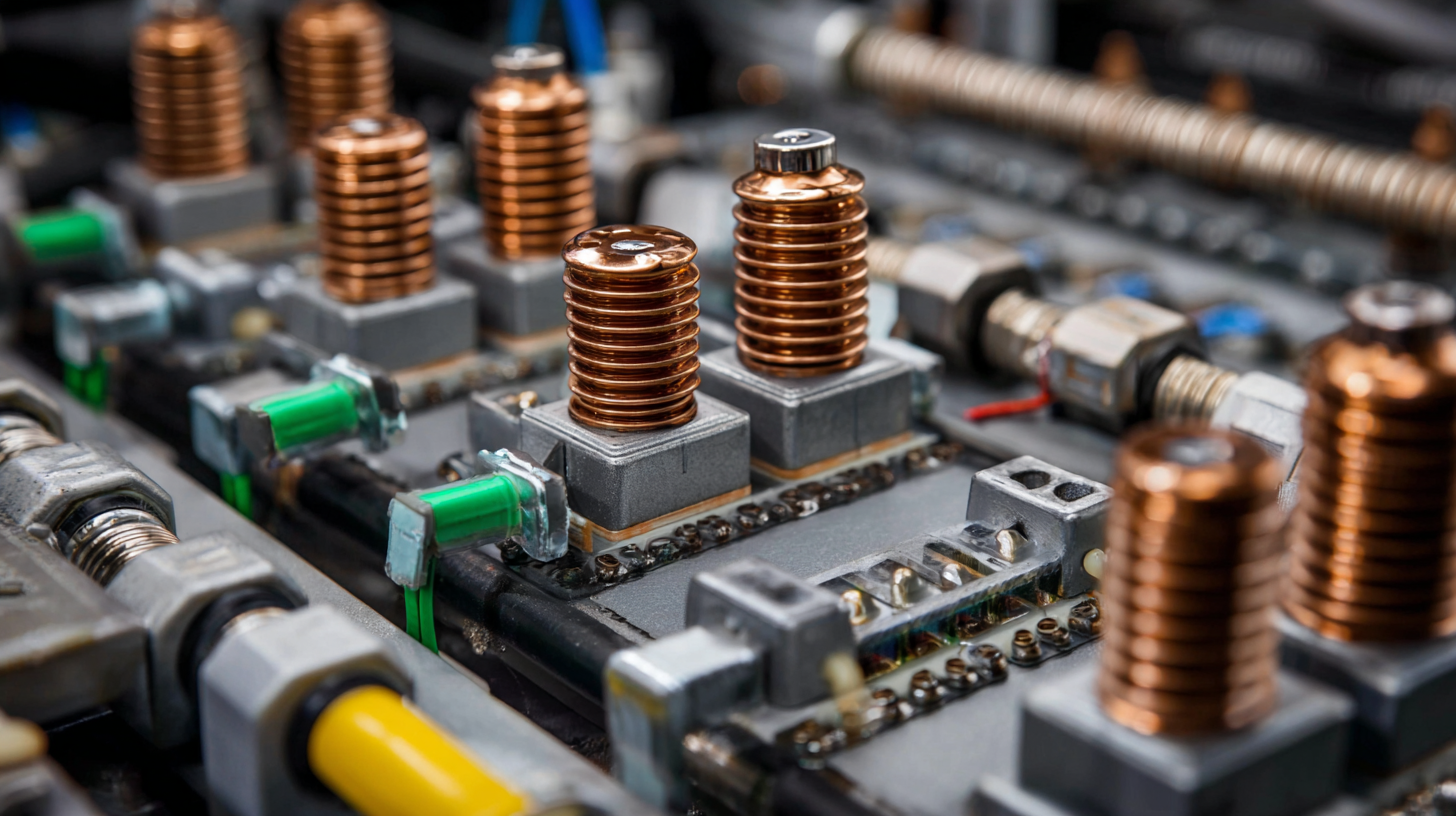

When evaluating electrical conductor insulation materials, several key factors stand out. The choice of insulation impacts not only the performance but also the longevity and safety of electrical systems. According to the International Electrotechnical Commission (IEC), materials like PVC, rubber, and XLPE (cross-linked polyethylene) are commonly used due to their excellent insulating properties and resistance to environmental factors. It is essential to consider the thermal and electrical characteristics of these materials, as they can significantly affect energy efficiency and heat dissipation within the system.

Tips for selecting the right insulator include examining the temperature ratings and voltage capabilities of the material. For example, XLPE can operate effectively at elevated temperatures, making it suitable for high-voltage applications. Additionally, consider the moisture resistance of the insulation; materials with higher moisture resistance prevent degradation in damp environments, contributing to a longer lifespan. The proper assessment of these factors is crucial in aligning with industry standards and ensuring operational reliability.

Furthermore, pricing and availability are practical considerations. Recent reports indicate a trend in sourcing sustainable materials that not only comply with performance requirements but also meet environmental regulations. Understanding the balance between performance and cost will guide decisions in selecting insulation materials that optimize both budget and efficiency.

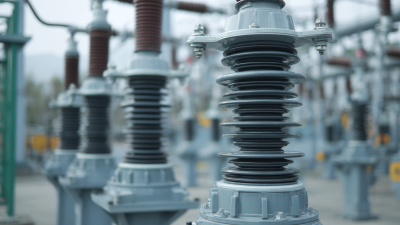

When selecting electrical conductor insulators, assessing the environmental conditions is crucial for ensuring optimal performance. Factors such as temperature, humidity, and pollution levels can significantly affect an insulator's longevity and efficiency. For instance, in coastal areas, high humidity combined with saline conditions can lead to rapid degradation of insulators, necessitating the use of materials that are resistant to corrosion and moisture absorption. Therefore, a thorough understanding of local environmental factors is essential for making informed decisions.

Moreover, the presence of pollutants, such as industrial emissions, can impair insulator functionality through the formation of conductive layers on their surface. This is particularly important in urban settings where air quality may be compromised. Selecting insulators designed to withstand specific types of pollution can enhance reliability and performance. Furthermore, climate factors such as extreme temperatures or storm exposure require careful consideration, as different materials exhibit varied resilience. By aligning the choice of insulator with the unique environmental conditions of the installation site, one can significantly improve the operational stability and lifespan of electrical systems.

When selecting electrical conductor insulators, understanding industry standards and certifications is crucial for ensuring safety and reliability. Key standards such as IEEE (Institute of Electrical and Electronics Engineers) 486-2014 provide guidelines for the design and performance of insulators used in electrical applications. Furthermore, the IEC (International Electrotechnical Commission) sets international benchmarks through standards like IEC 60287, which help engineers assess the thermal characteristics of insulation systems, thereby facilitating informed decisions.

Certifications from recognized bodies such as UL (Underwriters Laboratories) and CE (Conformité Européenne) also play an essential role in the selection process. These certifications indicate that the products have undergone rigorous testing to meet safety regulations and performance criteria. For instance, according to a recent report by MarketsandMarkets, the electrical insulation market is projected to grow from USD 88.7 billion in 2020 to USD 118.8 billion by 2025, driven by rising safety standards and a focus on energy efficiency. Therefore, adhering to these standards and certifications not only ensures compliance but also enhances the longevity and performance of electrical systems.

When selecting electrical conductor insulators, it's crucial to avoid common pitfalls that can lead to inefficiencies and safety hazards. One frequent mistake is overlooking the environmental conditions in which the insulation will operate. Factors such as temperature fluctuations, humidity, and exposure to chemicals can significantly affect material performance. As a tip, always assess the operating environment first and choose insulators that are specifically rated for those conditions.

Another common error is selecting insulators based solely on cost. While budget is an important consideration, compromising on quality can result in increased maintenance costs and system failures in the long run. Instead, focus on the overall value by considering the lifespan and reliability of the chosen insulators. A helpful tip is to consult industry standards and manufacturer specifications to ensure that the insulation provides the necessary performance without cutting corners.

Lastly, many professionals neglect to involve experts in the selection process, leading to uninformed decisions. Engaging with engineers or specialists can provide valuable insights into material properties and application suitability. A smart approach is to seek recommendations from experienced professionals and review case studies that highlight successful insulation solutions. This way, you can avoid common mistakes and make an informed choice.

| Type of Insulator | Material | Max Voltage Rating | Temperature Range | Common Applications | Common Mistakes to Avoid |

|---|---|---|---|---|---|

| Ceramic Insulators | Porcelain | Up to 100kV | -40°C to 50°C | Power Transmission, Distribution | Ignoring environmental factors |

| Polymer Insulators | Silicone Rubber | Up to 500kV | -50°C to 90°C | Railways, Transmission Lines | Misjudging mechanical strength |

| Glass Insulators | Soda-lime Glass | Up to 230kV | -30°C to 60°C | Communication Lines, Electricity Networks | Overlooking thermal expansion factors |

| Composite Insulators | Fiberglass Reinforced Plastic | Up to 400kV | -40°C to 80°C | High Voltage Lines | Neglecting UV resistance properties |