Leave Your Message

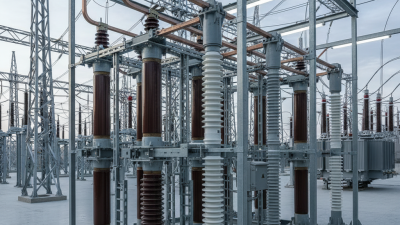

In the realm of electrical engineering, selecting the right components is crucial for the success of any project, particularly when it comes to ensuring safety and efficiency. For those working with low voltage applications, the choice of a Low Voltage Insulator can significantly impact the overall performance of the electrical system. According to Dr. Emily Carter, a leading expert in electrical insulative technologies, “The correct selection of insulators not only safeguards the system but also enhances its longevity.” This statement highlights the importance of making informed decisions when choosing a Low Voltage Insulator.

When embarking on a project that involves electrical systems, it is essential to understand the various factors that influence the selection of an appropriate Low Voltage Insulator. From environmental conditions to voltage ratings, each aspect plays a vital role in determining the right insulator for the task at hand. This introduction aims to guide professionals and enthusiasts alike in identifying the key considerations for choosing the best Low Voltage Insulator to meet their specific project requirements. By staying informed and applying expert insights, one can ensure the reliability and safety of their electrical installations.

Low voltage insulators play a crucial role in the safety and efficiency of electrical projects. They are designed to prevent short circuits, protect electrical components, and ensure that voltage levels remain within safe parameters. Understanding the different types of low voltage insulators, such as porcelain, glass, and polymer varieties, is essential for selecting the right one for your application. Each type has unique properties that determine its effectiveness in different environmental conditions, making it vital to choose wisely based on the specifics of your project.

**Tip:** Consider the environmental factors where the insulator will be used. For example, if your project is in a high-humidity area, a polymer insulator may be more suitable due to its resistance to moisture-related degradation.

When evaluating low voltage insulators, also take into account their dielectric strength and mechanical durability. An insulator with high dielectric strength can handle more voltage without risking failure, while robust mechanical properties ensure longevity even under harsh conditions.

**Tip:** Always prioritize insulators that comply with relevant safety standards. Doing so not only guarantees quality but also minimizes the risk of potential hazards during operation. Choosing the right low voltage insulator is a key step towards ensuring a safe and efficient electrical project.

| Insulator Type | Voltage Rating (V) | Material | Temperature Range (°C) | Typical Applications |

|---|---|---|---|---|

| Porcelain Insulator | 0 - 1000 | Porcelain | -40 to 120 | Garden Lighting, Street Lighting |

| Polymeric Insulator | 0 - 600 | Polymer | -40 to 100 | Power Distribution, Telecommunications |

| Glass Insulator | 0 - 760 | Glass | -50 to 150 | Vintage Lighting, Electrical Railways |

| Silicone Rubber Insulator | 0 - 1000 | Silicone Rubber | -40 to 200 | High Voltage Applications, Outdoor Equipment |

| Polyethylene Insulator | 0 - 300 | Polyethylene | -20 to 85 | Low Voltage Connections, Home Appliances |

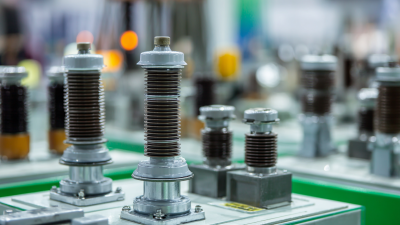

When selecting the ideal low voltage insulator for your electrical projects, understanding the various types available in the market is crucial. Low voltage insulators come in different materials and designs, tailored for specific applications and environments. Common types include ceramic insulators, which are known for their durability and resistance to weather conditions, making them suitable for outdoor installations.

Another popular choice is polymer insulators, which are lightweight and less prone to damage from thermal expansion and contraction. These insulators are particularly effective in urban settings where space is limited.

In addition to ceramic and polymer options, glass insulators also play a significant role in low voltage applications. They provide excellent electrical insulation and are resistant to ultraviolet light, ensuring longevity even in harsh conditions. Each type of insulator comes with its own advantages, such as moisture resistance, mechanical strength, and ease of installation. When choosing an insulator, it’s essential to consider factors like the environmental conditions, the voltage range, and the specific requirements of your electrical project to ensure optimal performance and safety.

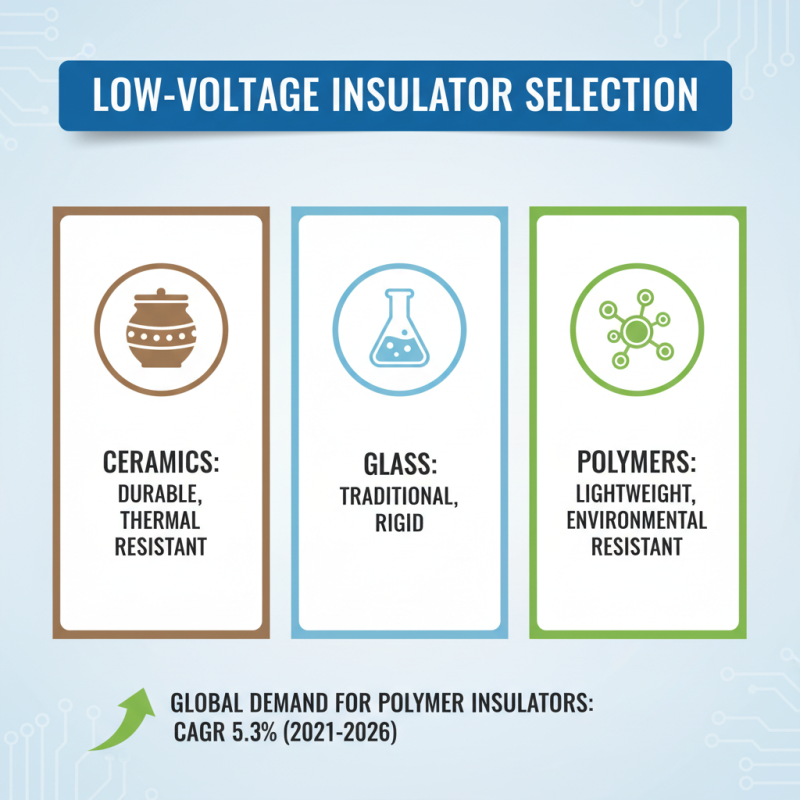

When selecting low voltage insulators for electrical projects, several key factors must be taken into consideration to ensure optimal performance and safety. One of the primary considerations is the material of the insulator. Common materials include ceramics, glass, and various types of polymers. According to industry reports, ceramic insulators are often favored for their durability and thermal resistance, while polymer insulators have gained popularity due to their lightweight and resistance to environmental degradation. In fact, the global demand for polymer insulators has been projected to grow at a CAGR of 5.3% from 2021 to 2026, underscoring their importance in the modern electrical landscape.

Another significant factor is the electrical and mechanical strength of the insulator. It is crucial to evaluate the insulator's voltage rating, which must exceed the maximum voltage of the system to prevent breakdown and ensure reliability. The International Electrotechnical Commission (IEC) standards provide guidelines for these ratings, categorizing them based on the application and environmental conditions. Additionally, the insulator's mechanical properties, such as its resistance to bending and impact, are vital for applications that may experience physical strain. Recent findings suggest that insulators designed with optimized mechanical characteristics can enhance the lifespan of electrical systems by up to 30%, illustrating the importance of robust design in insulator selection.

When it comes to low voltage insulators, proper installation and maintenance are paramount to ensuring their long-term efficacy and safety in electrical projects. According to the IEEE (Institute of Electrical and Electronics Engineers), poorly installed insulators can lead to significant energy losses, estimated to be around 5-10% in low voltage systems.

To begin with, installers should ensure that the insulator type chosen matches the environmental conditions it will be exposed to, as factors like humidity and temperature swings can significantly affect performance. Insulators made from materials with high dielectric strength, such as certain types of ceramics or plastics, are recommended for environments subject to moisture.

Once the appropriate insulators are selected and installed, regular maintenance is crucial. A study published by the International Electrotechnical Commission (IEC) highlights the importance of routine inspections to detect signs of wear, degradation, or contamination that can compromise an insulator’s effectiveness. Ideally, maintenance should include cleaning the insulators to remove contaminants that could create conductive paths, as well as visual inspections to check for cracks or physical damage. Keeping records of inspection schedules can greatly increase reliability and provide insights into the lifecycle of the insulators, helping to mitigate unexpected failures and extend their service life.

By adhering to these installation and maintenance guidelines, professionals can ensure optimal operation and longevity of low voltage insulators in their electrical setups.

When selecting low voltage insulators for electrical projects, adhering to safety standards and compliance is paramount. According to the International Electrotechnical Commission (IEC), insulators must meet specific guidelines to ensure they can withstand environmental factors while maintaining performance. These standards, such as IEC 60168, outline the necessary mechanical strength and electrical insulating properties essential for safe operation. It is notable that insulators are tested for their capability to endure variable temperatures and humidity levels, both of which can significantly influence their longevity and effectiveness.

Moreover, compliance with safety standards not only protects equipment and personnel but also enhances the reliability of electrical systems. The National Electrical Manufacturers Association (NEMA) indicates that low voltage insulators are critical in preventing electrical faults, which can lead to system failures or hazardous situations. Inadequate insulator selection can result in increased maintenance costs and decreased efficiency, highlighting the importance of rigorously following established compliance protocols. By prioritizing safety in choosing the correct insulator, electrical projects can achieve optimal performance while ensuring the safety of all involved.