Leave Your Message

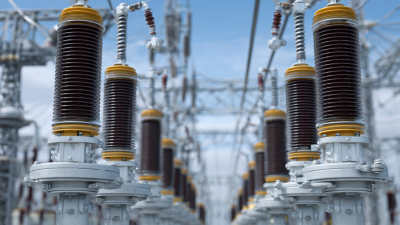

The increasing demand for reliable and efficient power systems has led to a growing interest in innovative materials, particularly in high voltage applications where safety and durability are paramount. Epoxy insulators have emerged as a preferred choice in this field, thanks to their remarkable properties that enhance performance and resilience under challenging conditions. Renowned expert Dr. John Smith, a leader in electrical engineering and materials science, emphasizes the significance of these insulators by stating, “Epoxy insulators offer unmatched dielectric strength and mechanical stability, making them ideal for high voltage applications.”

In a landscape where electrical infrastructure is continuously evolving, choosing the right insulating material is crucial for both operational efficiency and safety. Epoxy insulators not only provide superior electrical insulation but also withstand environmental stressors, ensuring longevity and reduced maintenance costs. As industries seek to maximize productivity while minimizing risks, the advantages of epoxy insulators become increasingly clear. Thus, understanding their role in high voltage systems is essential for stakeholders looking to optimize their operations and safeguard their investments.

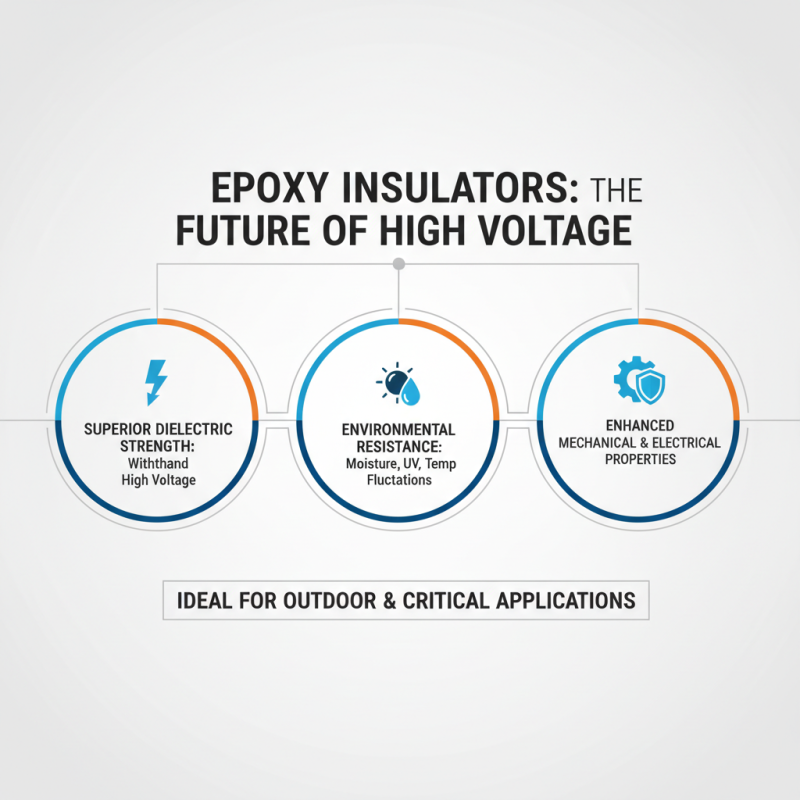

Epoxy insulators are increasingly recognized for their superior performance in high voltage applications, thanks to their exceptional properties that cater to the demands of modern electrical systems. One of the primary benefits of epoxy insulators is their excellent electrical insulation performance, which is crucial in preventing electrical breakdowns under extreme voltages. According to a report by the International Electrotechnical Commission (IEC), epoxy resin insulators exhibit dielectric strengths exceeding 25 kV/mm, making them suitable for high voltage environments.

Another significant advantage of epoxy insulators is their mechanical strength and durability. These materials resist mechanical stresses and environmental factors, such as moisture and UV exposure, ensuring a long lifespan in outdoor applications. A recent study by the Electric Power Research Institute (EPRI) notes that epoxy-based insulators maintain their integrity under harsh conditions, leading to a reduction in maintenance costs by up to 30% compared to traditional materials.

Tips: When selecting epoxy insulators, consider the specific voltage ratings and environmental conditions they will be exposed to. Ensure the chosen product has undergone rigorous testing to meet international standards, as this will enhance reliability and operational safety in high voltage systems.

Epoxy insulators are increasingly favored in high-voltage applications due to their exceptional electrical and mechanical properties. One of the primary advantages of using epoxy insulators is their superior dielectric strength, which enables them to withstand high voltage levels without breaking down. This insulator type is also resistant to environmental factors such as moisture, UV radiation, and temperature fluctuations, making them ideal for outdoor installations.

When selecting epoxy insulators, consider these tips: ensure compatibility with your specific electrical system requirements, including voltage ratings and environmental conditions. It’s also advisable to consult with manufacturers about the insulator’s lifespan and resistance to aging, as these factors play a crucial role in long-term performance.

Another significant benefit of epoxy insulators is their lightweight nature, which facilitates easier handling and installation. Additionally, their resistance to chemical exposure further enhances their durability in industrial settings. For optimal performance, regularly inspect the insulators for signs of wear or damage, addressing any issues promptly to maintain system integrity and safety.

Epoxy insulators have become increasingly popular in high voltage applications, primarily due to their superior performance compared to traditional materials like porcelain and glass. One of the most significant advantages of epoxy is its lightweight nature, which allows for easier installation and reduces overall structural loads. Moreover, epoxy insulators exhibit excellent mechanical strength and resistance to electrical tracking, ensuring reliability in harsh operating conditions. Unlike porcelain, which can be brittle and prone to cracking under stress, epoxy insulators provide a more robust solution with enhanced durability.

In terms of electrical performance, epoxy materials demonstrate a lower dielectric constant and higher dielectric strength, making them ideal for insulating in high voltage environments. This characteristic minimizes power losses and improves the overall efficiency of electrical systems. Traditional materials, while they have been trusted for decades, often struggle with issues such as moisture absorption and susceptibility to thermal cycling, leading to decreased performance over time. In contrast, the moisture-resistant properties of epoxy not only enhance its longevity but also ensure that it maintains its insulative properties under varying environmental conditions. As industries continue to evolve, the shift toward epoxy insulators represents a significant step forward in ensuring safety and efficiency in high voltage applications.

| Property | Epoxy Insulators | Traditional Materials |

|---|---|---|

| Dielectric Strength (kV/mm) | 20-30 | 15-25 |

| Water Absorption (%) | < 1 | > 2 |

| Thermal Conductivity (W/m·K) | 0.2-0.3 | 0.1-0.2 |

| Mechanical Strength (MPa) | 80-150 | 50-100 |

| UV Resistance | Excellent | Moderate |

| Lifespan (Years) | 30+ | 15-20 |

| Cost (per unit) | $$ | $ |

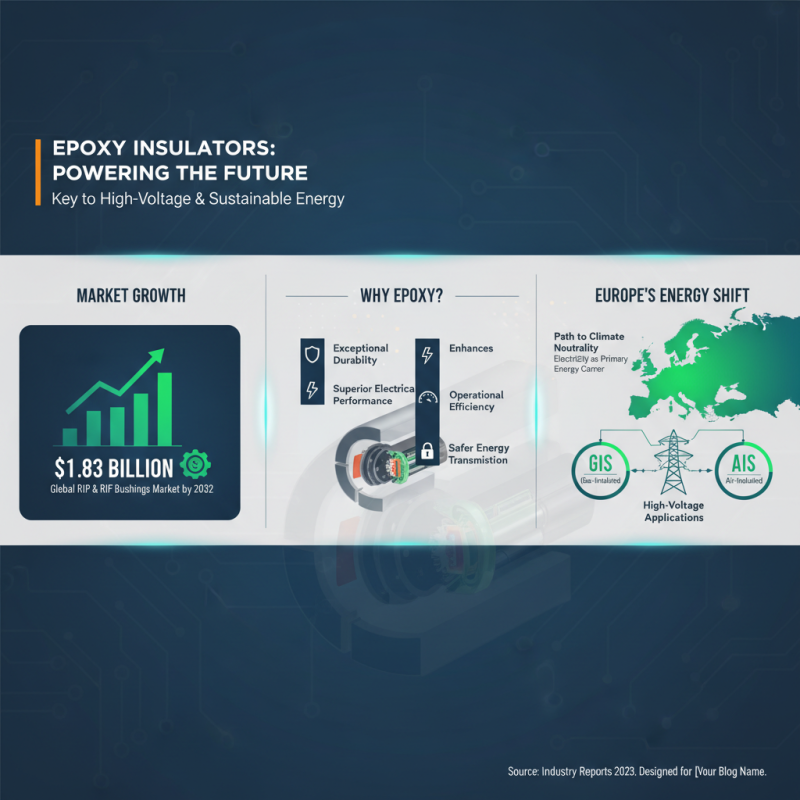

Epoxy insulators have emerged as a crucial component in high voltage applications, primarily due to their exceptional durability and electrical performance. With the global RIP & RIF bushings market projected to reach $1.83 billion by 2032, the adoption of epoxy insulators in substations, particularly gas-insulated (GIS) and air-insulated (AIS) types, is noteworthy. These insulators not only enhance operational efficiency but also ensure safer energy transmission, aligning perfectly with the ongoing shift towards electricity as a primary energy carrier in Europe’s path to climate neutrality.

In addition to their robust mechanical properties, epoxy insulators are increasingly favored for their resistance to environmental degradation. The latest studies reveal that epoxy-based dielectrics play a critical role in modern microelectronics and energy systems. As highlighted in various market analysis reports, the enhanced insulation performance of materials like HTV silicone rubber nanocomposites, filled with nano-TiO, further emphasizes the continuous evolution of insulating materials in high voltage applications.

**Tip:** When selecting insulation materials for high voltage equipment, consider factors such as environmental exposure, thermal stability, and electrical breakdown strength. Regular testing for partial versus corona discharges can improve maintenance strategies and prolong the lifespan of electrical equipment. Always consult recent industry reports for the most up-to-date information on material performance and market trends.

Epoxy insulators have become a popular choice for high voltage applications due to their exceptional performance in harsh environments. One of the pivotal factors contributing to their selection is their remarkable longevity and low maintenance requirements. Unlike traditional materials, epoxy displays superior resistance to moisture, chemicals, and UV radiation, making it an ideal solution for outdoor and industrial applications. This durability significantly reduces the frequency of replacements and repairs, ultimately lowering operational costs.

**Tips for Maintenance:**

Regular inspections are crucial to ensure the integrity of epoxy insulators. Look for any signs of surface degradation or contamination, as these can impact performance. Additionally, consider implementing a washing schedule to remove any accumulated dirt or pollutants, which can be particularly damaging in coastal or industrial areas.

Another advantage of epoxy insulators is their ability to withstand extreme temperatures. This resilience means they maintain functionality even under fluctuating thermal conditions, ensuring reliable operation. Utilizing these insulators not only enhances system performance but also minimizes maintenance interruptions, making them a smart choice for critical infrastructure.

**Tips for Longevity:**

When installing epoxy insulators, ensure proper sealing and securing to prevent moisture ingress. Proper alignment and support can also extend their lifespan by reducing mechanical stress during operation. Regular documentation of maintenance activities will help track performance over time, allowing for early identification of potential issues.