Leave Your Message

In the ever-evolving landscape of electrical engineering, selecting the right components is crucial for optimal performance and safety. Among these components, Switchgear Insulators play a vital role in ensuring the reliability and efficiency of electrical systems. However, choosing the best insulators can be challenging due to the myriad of options available and the stringent industry standards that must be met. This ultimate checklist is designed to guide you through the essential factors to consider, emphasizing both performance data and compliance with relevant standards.

By understanding the key attributes that differentiate high-quality Switchgear Insulators, you can make informed decisions that enhance the longevity and functionality of your electrical infrastructure. Join us as we explore the critical aspects to help you navigate this important selection process effectively.

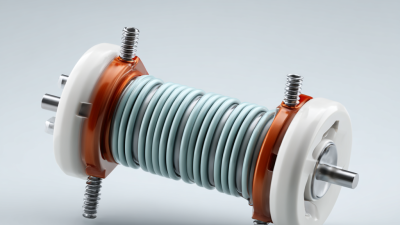

When selecting switchgear insulators, understanding the key factors that influence their performance against industry standards is essential. One of the primary considerations is the insulator's dielectric strength, which determines its ability to withstand electrical stress without breaking down. High-quality materials, such as porcelain and composite polymers, can enhance this property, making them ideal for high-voltage applications. Additionally, manufacturers should adhere to established industry standards like IEEE and IEC to ensure reliability and safety in various environmental conditions.

Another crucial aspect to evaluate is the mechanical robustness of the insulators. The impact resistance, tensile strength, and weathering capabilities play critical roles in ensuring long-term durability. Insulators must be able to withstand harsh weather conditions, UV exposure, and pollution without degrading over time. Testing methods like mechanical load testing and artificial aging simulations can provide valuable performance data. By carefully analyzing these factors, professionals can make informed decisions, ultimately leading to safer and more efficient switchgear systems that meet or exceed industry benchmarks.

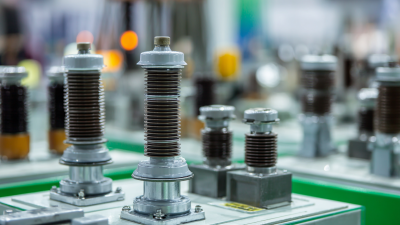

Switchgear insulators play a crucial role in ensuring the reliability and safety of electrical systems. When selecting the appropriate insulators, it’s essential to consider various types available, each with unique performance characteristics.

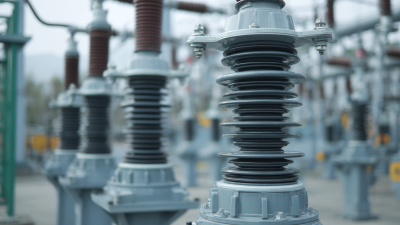

Porcelain insulators, known for their durability and resistance to harsh environmental conditions, are widely used in outdoor applications. Their ability to withstand electrical stress while providing excellent mechanical strength makes them a popular choice in substations.

On the other hand, composite insulators have gained traction due to their lightweight nature and superior hydrophobic properties, making them less susceptible to pollution and moisture-related failures. These insulators perform well in environments with high contamination levels, offering longevity and reduced maintenance costs. Additionally, polymer insulators feature robust designs that aid in minimizing flashover incidents, ensuring optimal operation in diverse weather conditions.

Evaluating these options based on industry standards and performance data is crucial for making informed decisions and optimizing switchgear functionality.

When selecting switchgear insulators, understanding the material choices is crucial for achieving optimal efficiency. The performance of insulators largely depends on their thermal properties, which can greatly influence the overall energy performance of buildings. Recent advancements in sustainable insulation materials highlight the importance of selecting the right materials that not only meet industry standards but also contribute to energy efficiency goals. Materials such as glass mineral wool have demonstrated promising capabilities in reducing carbon emissions while enhancing the thermal insulation performance of buildings.

Moreover, the ongoing shift towards sustainable building practices has led to the development of bio-based insulation materials, which offer a viable alternative to conventional options. These materials not only improve energy efficiency but also provide a lower environmental impact. By understanding the characteristics and benefits of various insulation materials, industry professionals can make informed decisions that support energy-efficient designs and sustainable construction practices. As the demand for high-performance insulators continues to rise, staying abreast of market trends and technological innovations will be essential in selecting the most effective switchgear insulators for future projects.

When selecting insulators for switchgear applications, understanding industry standards is crucial for ensuring reliability and safety.

Various organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established guidelines that define the performance and testing requirements for insulators.

These standards cover critical aspects such as dielectric strength, pollution resistance, and thermal performance, all of which influence the insulator's lifecycle and operational reliability.

Another vital consideration is the certification of insulators according to these standards. Insulators that meet or exceed established benchmarks provide assurance regarding their performance in real-world conditions.

It's important to assess whether a product has been rigorously tested in accordance with relevant standards, as this can impact both the functionality of the switchgear and the overall safety of the electrical system. By choosing insulators that adhere to industry guidelines, you can mitigate risks related to equipment failures and ensure that your electrical systems can perform optimally under diverse environmental conditions.

When selecting switchgear insulators, it is crucial to delve into performance data to ensure optimal effectiveness in real-world scenarios. Performance metrics, such as dielectric strength, thermal stability, and moisture resistance, provide critical insights into how insulators will behave under various environmental conditions. Analyzing field data from existing installations allows engineers to compare different materials and designs, assessing their performance over time and under stress. This data-centric approach not only enhances decision-making but also underscores the importance of empirical insights in the evaluation process.

In practical applications, insulators often face a dynamic range of challenges, including temperature fluctuations, icing, and pollution accumulation, which can significantly impact their performance. Case studies highlighting failures and successes of particular insulator types in specific environments offer valuable lessons. By evaluating performance data, professionals can identify which insulators have demonstrated resilience and reliability, thereby guiding future installations and maintenance strategies. Ultimately, grounded in real-world performance data, the selection of switchgear insulators becomes a more informed and strategic process, leading to enhanced operational reliability and safety in electrical systems.