Leave Your Message

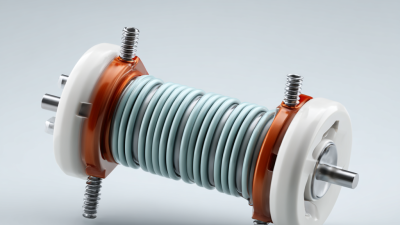

In the realm of electrical infrastructure, selecting the appropriate Medium Voltage Insulator is crucial for ensuring reliability and safety in power systems. With a variety of options available, understanding the alternatives to traditional insulators is essential for meeting specific operational demands. This blog will delve into the various types of Medium Voltage Insulators—ranging from ceramic and glass to polymer—and their unique benefits and drawbacks. By evaluating factors such as environmental conditions, mechanical strength, and electrical performance, we aim to provide a comprehensive checklist that will aid engineers and decision-makers in choosing the right insulator type for their unique applications. As the electrical industry continues to evolve, staying informed about alternative insulator technologies can significantly enhance system efficiency and durability, ultimately contributing to a more robust power distribution network.

When selecting the right medium voltage insulator, several key considerations must be taken into account. The insulation type is paramount among these, as it can significantly impact performance and longevity. According to recent market research in the Americas Medium-Voltage Cables sector, insulators made from Ethylene Propylene Rubber (EPR), Cross-Linked Polyethylene (XLPE), and High-Temperature Ethylene Propylene Rubber (HEPR) are among the most recognized choices. Each material offers distinct benefits, such as EPR’s superior resistance to environmental stressors and XLPE’s robust thermal stability, which can enhance operational efficiency across the voltage ranges of up to 5 kV, 5-15 kV, and 15-30 kV.

Another critical consideration is the voltage rating itself. Understanding your specific application requirements and matching them to the appropriate voltage category is essential for safety and functionality. Industry reports indicate that the selection of insulators tailored to specific voltage requirements can prolong the lifespan of electrical systems while minimizing maintenance costs. Additionally, consulting engineers must consider environmental factors such as exposure to moisture, pollution, and temperature extremes to ensure optimal performance of the insulators in real-world conditions.

When selecting the appropriate medium voltage insulator, understanding the various types available is crucial. There are several factors to consider, such as the electrical properties, environmental conditions, and mechanical strength required for your specific application. For instance, polymeric insulators, known for their superior resistance to pollution and environmental stress, are increasingly favored in modern installations due to their lightweight design and ease of installation. In contrast, traditional ceramic insulators may provide better performance in extremely high-voltage situations but are generally more prone to damage.

Additionally, it's essential to assess the performance characteristics of insulators under high-stress conditions, such as concave-front lightning strikes and induced over-voltages, which can significantly impact their effectiveness. Rapid voltage changes with short tails can lead to insulation failure if not properly accounted for. Emerging technologies, like machine learning, are now being utilized to classify contamination on polluted high voltage insulators, offering innovative solutions to enhance reliability in power systems. By evaluating these insights and aligning them with your project requirements, you can make a more informed decision on the best medium voltage insulator for your needs.

When selecting the right medium voltage insulator, evaluating performance standards and specifications is critical to ensure optimal functionality and longevity. The effectiveness of an insulator largely depends on its ability to withstand electrical stresses, environmental conditions, and physical impacts. Key performance standards, such as IEC 60273 and ANSI C29.9, provide benchmarks for evaluating the dielectric strength, thermal stability, and mechanical properties of insulators. Understanding these standards can help you identify products that meet or exceed the requirements for your specific application.

In addition to international standards, certifications play a vital role in the selection process. Insulators should be tested and certified by recognized agencies to guarantee their performance under various conditions. Furthermore, considering the environmental factors—such as pollution levels, humidity, and temperature fluctuations—will help in choosing materials that resist aging and degradation. Opting for insulators that have proven performance and are compliant with applicable specifications not only enhances safety but also contributes to the reliability and efficiency of your electrical infrastructure.

When selecting the right medium voltage insulator, considering installation and maintenance factors is critical to ensuring reliable and long-lasting performance. According to the IEEE Standard 987, the choice of insulator type directly impacts the ease of installation and ongoing maintenance requirements. For instance, materials such as silicone rubber have shown improved hydrophobic properties, which can drastically reduce maintenance tasks compared to traditional ceramic insulators. This is particularly valuable in regions with high pollution levels or frequent rainfall, where accumulation on insulators can lead to flashovers and operational failures.

Incorporating expert recommendations, a study from the Electric Power Research Institute (EPRI) emphasizes the significance of assessing installation ergonomics and the environmental conditions at the installation site. Factors such as ambient temperature, humidity, and exposure to contaminants should influence the choice of insulators. Additionally, proper installation procedures, as outlined in the Institute of Electrical and Electronics Engineers (IEEE) guidelines, highlight the need for trained personnel to ensure that insulators are correctly mounted to avoid premature wear. By considering these installation and maintenance factors, utilities can enhance the reliability and longevity of their medium voltage insulation systems.

When budgeting for medium voltage insulators, it is essential to grasp the various cost factors that can impact your project. According to a report from the International Electrotechnical Commission (IEC), the initial purchase price of insulators can vary significantly based on materials, with porcelain and composite options ranging from $10 to $50 per unit. However, it’s crucial to consider not only upfront costs but also long-term expenses associated with maintenance and replacement. The total lifecycle cost of insulators is often underestimated, but studies suggest that maintenance can account for up to 60% of operational costs over their lifespan.

Furthermore, geographical location plays a significant role in pricing, as transportation and local market conditions can influence final costs. A recent analysis from the Global Insulator Market Report indicates that regions with higher demand, such as North America and parts of Asia, experience a 15-25% markup on insulator pricing due to increased logistics costs and competitive bidding. By carefully considering these elements and conducting thorough cost analysis, buyers can optimize their budgets to ensure they select the right medium voltage insulator that meets both their performance and economic expectations.

| Insulator Type | Voltage Rating (kV) | Material | Average Cost ($) | Lifespan (Years) | Maintenance Frequency (Years) |

|---|---|---|---|---|---|

| Porcelain Insulator | 15 | Porcelain | 120 | 30 | 5 |

| Polymer Insulator | 27 | Composite | 150 | 25 | 3 |

| Glass Insulator | 33 | Glass | 170 | 35 | 7 |

| Silicone Insulator | 13.8 | Silicone | 130 | 20 | 4 |