Leave Your Message

In the realm of electrical engineering, safety and performance are paramount, especially when it comes to the effective management of power distribution. One of the critical components that ensure these aspects are upheld is the Busbar Insulator. According to Dr. Emily Carter, a leading expert in the field of electrical insulators, "The role of Busbar Insulators cannot be overstated; they are vital for preventing electrical failures and ensuring the longevity of power systems."

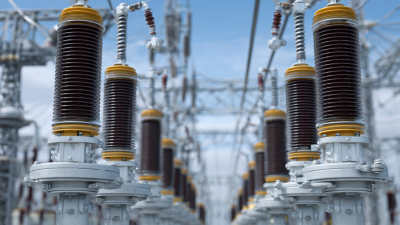

Busbar Insulators serve as a defensive barrier, protecting both equipment and personnel from potential electrical hazards. They are designed to withstand high voltages and environmental stressors, thereby playing a crucial role in maintaining the reliability of electrical networks. Their significance is underscored by their ability to enhance operational efficiency while minimizing the risk of catastrophic failures that can lead to safety incidents or system downtimes.

In conclusion, the importance of Busbar Insulators in the electrical industry extends beyond mere functionality; they are essential for establishing a safe operating environment. As technological advancements continue to evolve, understanding the critical nature of Busbar Insulators will be increasingly important for professionals aiming to achieve optimal performance in electrical systems.

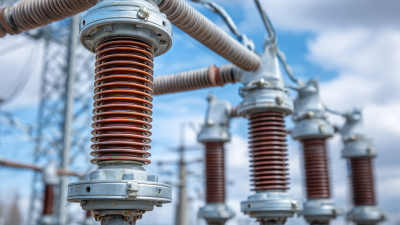

Busbar insulators play a crucial role in maintaining the safety and performance of electrical systems. These components are designed to support conductive materials while preventing unwanted electrical discharge. Without insulators, electrical systems risk short circuits, which can lead to equipment failure or more severe consequences, such as electrical fires. The ability of insulators to withstand high voltage levels is fundamental to their effectiveness, ensuring that energy can flow through busbars safely.

In addition to safety, busbar insulators contribute to the overall efficiency of electrical systems. By minimizing energy losses and ensuring stable operation, they enhance system reliability. In environments with fluctuating temperatures or humidity, high-quality insulators prevent moisture ingress and deterioration, which can compromise system integrity. Therefore, the importance of selecting the right busbar insulators becomes evident—doing so not only protects the immediate electrical infrastructure but also extends the lifespan of the entire system, making them indispensable in modern electrical applications.

Busbar insulators play a crucial role in ensuring electrical safety and optimizing performance within power distribution systems. These essential components provide physical support and electrical insulation for busbars, which carry high current loads. According to the International Electrotechnical Commission (IEC), the failure of busbar insulation can lead to catastrophic electrical failures, with over 20% of electrical accidents attributed to improper insulation practices. This emphasizes the need for high-quality materials that can withstand extreme temperatures and environmental conditions, ensuring longevity and reliability in power systems.

Additionally, busbar insulators contribute to system efficiency by reducing energy losses caused by leakage currents. Studies indicate that proper insulation can minimize energy losses by up to 5%, which is particularly significant in large-scale industrial settings where operational costs can escalate quickly. Advanced materials such as silicone rubber and polymer composites are increasingly being utilized for their superior dielectric properties and resistance to thermal degradation, ensuring that busbar insulators not only meet safety standards but also enhance overall performance. By effectively managing electrical isolation and supporting high current transitions, busbar insulators remain a fundamental component in modern electrical infrastructure.

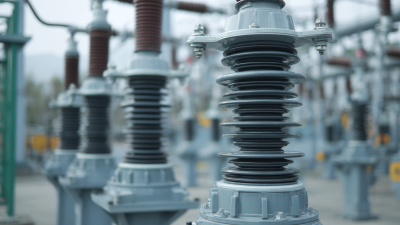

Busbar insulators play a crucial role in ensuring electrical safety and performance, particularly when it comes to material selection. The efficiency of these insulators largely depends on the materials from which they are made. For instance, materials like silicone rubber and thermosetting plastics offer excellent resistance to electrical stresses and environmental factors, making them ideal for high-voltage applications. Proper material selection not only enhances the durability of busbar insulators but also minimizes the risk of electrical failures.

Tips: When choosing busbar insulators, consider their thermal stability and dielectric strength. High-quality materials can withstand extreme temperatures and prevent breakdowns, ensuring optimal performance over time. Additionally, look for insulators with enhanced moisture resistance to protect against the damaging effects of humidity.

Furthermore, the impact of aging on insulator materials is significant. Over time, exposure to environmental stressors can compromise the integrity of insulators, leading to performance degradation. Therefore, selecting materials with intrinsic aging-resistant properties is vital for long-term reliability. Always consult with industry experts when assessing the compatibility of insulators with specific applications and environmental conditions.

Busbar insulators play a crucial role in maintaining electrical safety and optimal performance within various electrical systems. Industry standards and regulations are established to ensure that these insulators meet specific requirements regarding durability, thermal resistance, and dielectric strength. For instance, organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) provide guidelines and codes that manufacturers must adhere to, ensuring that busbar insulators can withstand high voltage and prevent electrical arcing.

Compliance with these standards not only guarantees the reliability of electrical equipment but also enhances safety in industrial environments. Regular inspections and adherence to regulatory measures minimize the risk of insulation failure, which could lead to dangerous electrical incidents or equipment damage. Additionally, advancements in materials technology, such as the use of polymer insulators, have further influenced regulatory frameworks, encouraging innovations that improve both safety and performance. By following industry standards related to busbar insulators, organizations can protect their infrastructure and personnel while ensuring uninterrupted electrical service.

Insulator malfunctions can have catastrophic consequences in electrical systems, as demonstrated by several case studies. One notable incident occurred at a major utility company where a failure in a busbar insulator led to a significant short circuit. The insulation breakdown caused a cascading failure that interrupted power supply to thousands of customers, resulting in economic losses and safety risks. Investigations revealed that the insulator had deteriorated due to environmental factors, underscoring the importance of regular inspections and maintenance.

Another example can be found in an industrial facility where an insulator's failure resulted in an electric arc. This incident caused severe damage to nearby equipment and posed a serious threat to personnel safety. The investigation pointed to improper installation and inadequate material selection as key contributing factors. These case studies highlight that neglecting the role of busbar insulators not only compromises electrical performance but also endangers safety, emphasizing the need for stringent standards and effective monitoring in electrical infrastructure.

| Incident ID | Date of Incident | Location | Type of Insulator | Failure Cause | Impact |

|---|---|---|---|---|---|

| 001 | 2023-01-15 | New York, USA | Polymer | Material Degradation | Loss of power for 6 hours |

| 002 | 2023-03-10 | London, UK | Ceramic | Cracking Due to Freeze and Thaw | 2 substations offline |

| 003 | 2023-05-25 | Tokyo, Japan | Glass | Insulation Failure | Electrical fire, building evacuation |

| 004 | 2023-08-14 | Berlin, Germany | Polymer | Manufacturing Defect | Power outage in residential area |

| 005 | 2023-09-30 | Sydney, Australia | Ceramic | Overheating | Loss of major grid connection |