Leave Your Message

In today's rapidly advancing electrical landscape, ensuring safety and efficiency in power distribution systems is paramount. Among the critical components that facilitate this are Grounding Busbar Insulators, which play a vital role in preventing electrical faults and enhancing the reliability of electrical grids. According to a recent industry report by Markets and Markets, the global busbar market is projected to reach $17.39 billion by 2026, growing at a CAGR of 5.6%. As the demand for effective grounding solutions escalates, selecting the right insulator becomes essential to mitigate risks and ensure operational continuity. This blog will explore the five best Grounding Busbar Insulator solutions tailored to meet diverse electrical needs, equipping professionals with the knowledge to make informed choices in safeguarding their systems.

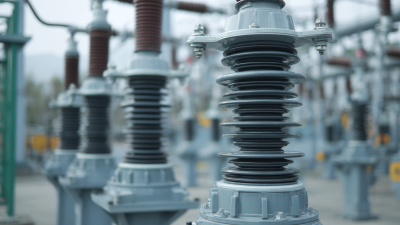

Grounding busbar insulators play a crucial role in ensuring electrical safety across various applications. Their primary function is to prevent unintentional electrical contact with grounded parts, thereby reducing the risk of shock and short circuits. When electrical systems operate at high voltages, the insulation properties of these busbars become vital in maintaining safety standards and protecting both equipment and personnel. Without proper insulators, the consequences can be dire, leading to equipment damage, safety hazards, and even potential fires.

Grounding busbar insulators play a crucial role in ensuring electrical safety across various applications. Their primary function is to prevent unintentional electrical contact with grounded parts, thereby reducing the risk of shock and short circuits. When electrical systems operate at high voltages, the insulation properties of these busbars become vital in maintaining safety standards and protecting both equipment and personnel. Without proper insulators, the consequences can be dire, leading to equipment damage, safety hazards, and even potential fires.

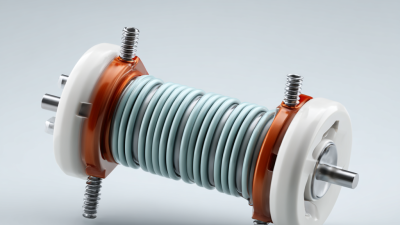

In addition to providing safety, grounding busbar insulators contribute to the overall efficiency of electrical systems. They help maintain electrical integrity by minimizing energy losses and improving system performance. By choosing the right insulator solution—such as epoxy resin, ceramic, or other materials—users can ensure that their electrical installations not only comply with regulations but also operate optimally. Understanding the relationship between grounding and insulation is essential for anyone involved in electrical design or maintenance, as it directly impacts reliability and safety in the engineering landscape.

When dealing with grounding busbar insulators, several common issues often arise, particularly in relation to code compliance and material degradation. One confusion stems from the National Electrical Code (NEC) requirements, especially regarding the installation of grounding systems. Misinterpretations can lead to installations that fail to meet safety standards, potentially jeopardizing the entire electrical system. It's crucial to ensure that grounding busbar insulators are not only compliant with local codes but also suitable for the specific environmental conditions they will face.

To avoid issues, one tip is to always verify materials used against the latest NEC requirements, as changes can occur between code revisions. Using insulated grounding busbars that are rated for the appropriate voltage and environmental factors—such as humidity and temperature—can significantly reduce the risk of malfunction. Additionally, regular inspections of the insulation integrity should be performed, as deterioration over time can lead to poor performance and increased safety hazards.

Another important consideration is the correct installation of the insulators. A common mistake is not securing the busbar properly, which can lead to movement and potential breakage. Ensure that all connections are tight and that the installation adheres to the instructions provided by the manufacturers. This attention to detail will help you maintain efficient and safe electrical systems.

When selecting a grounding busbar insulator, several key features can enhance performance and safety in your electrical systems. One crucial aspect is the material composition. High-quality insulators are typically made from durable materials like ceramic or high-grade polymers, which offer excellent dielectric strength and resistance to environmental factors. This ensures that the insulation remains effective over time, reducing the risk of failure due to wear or exposure to harsh conditions.

Another important feature to consider is the design of the insulator itself. A well-designed grounding busbar insulator should facilitate easy installation and maintenance while providing ample space for thermal expansion. Features such as reinforced edges and ribbed surfaces can enhance mechanical stability and reduce the likelihood of mechanical stress cracking. Additionally, compatibility with various busbar configurations and electrical loads is essential to ensure that the insulator performs well across different applications, helping to maintain system reliability and safety.

When it comes to electrical systems, choosing the right grounding busbar insulator is crucial for ensuring safety and efficiency. In our comparative review of the best grounding busbar insulator products, we analyzed various options based on performance, durability, and ease of installation. These insulators play a pivotal role in maintaining the integrity of electrical connections, particularly in environments subjected to fluctuating temperatures and moisture.

Furthermore, with the growing reliance on renewable energy sources, such as solar photovoltaic systems, the significance of robust electrical components continues to rise. Our review highlights products that not only meet rigorous safety standards but also align with the demands of modern grid-connected systems. These solutions are designed to withstand the challenges posed by fluctuating load requirements and environmental conditions, ensuring that electrical systems operate smoothly and reliably. As advancements in technology evolve, selecting the right insulator can significantly influence the overall efficiency and longevity of our electrical infrastructure.

When installing grounding busbar insulators, ensuring proper techniques and adherence to best practices can significantly enhance the performance and reliability of your electrical systems. First and foremost, it’s essential to choose the right size and type of insulator for your specific application. A well-matched insulator not only supports the busbar’s weight but also withstands the necessary electrical and environmental stress. It’s advisable to consult manufacturer guidelines or specification sheets for recommendations tailored to your unique setup.

During installation, proper torque settings should be applied to the mounting hardware to prevent mechanical failures that may lead to electrical faults. Additionally, maintaining a clean work environment is crucial; contaminants such as dust, metal shavings, or moisture can adversely affect insulation integrity. After installation, conduct regular inspections and testing to ensure that the insulators remain in optimal condition and to address any potential issues before they escalate. Following these installation tips will maximize the efficiency and longevity of your electrical systems, promoting better safety and performance.