Leave Your Message

In the ever-evolving field of electrical engineering, selecting the right supplier for Composite Insulators is crucial for ensuring safety, efficiency, and longevity in power transmission systems. As industry needs grow, the demand for high-quality, reliable components becomes more pronounced, making it imperative to partner with a leading manufacturer that excels in both product quality and service.

This blog explores practical strategies on how to identify and engage with the best suppliers of Composite Insulators in China, highlighting key factors such as production standards, certifications, and customer feedback. With the right approach, you can secure unmatched quality and performance for your electrical infrastructure, ultimately contributing to the success of your projects.

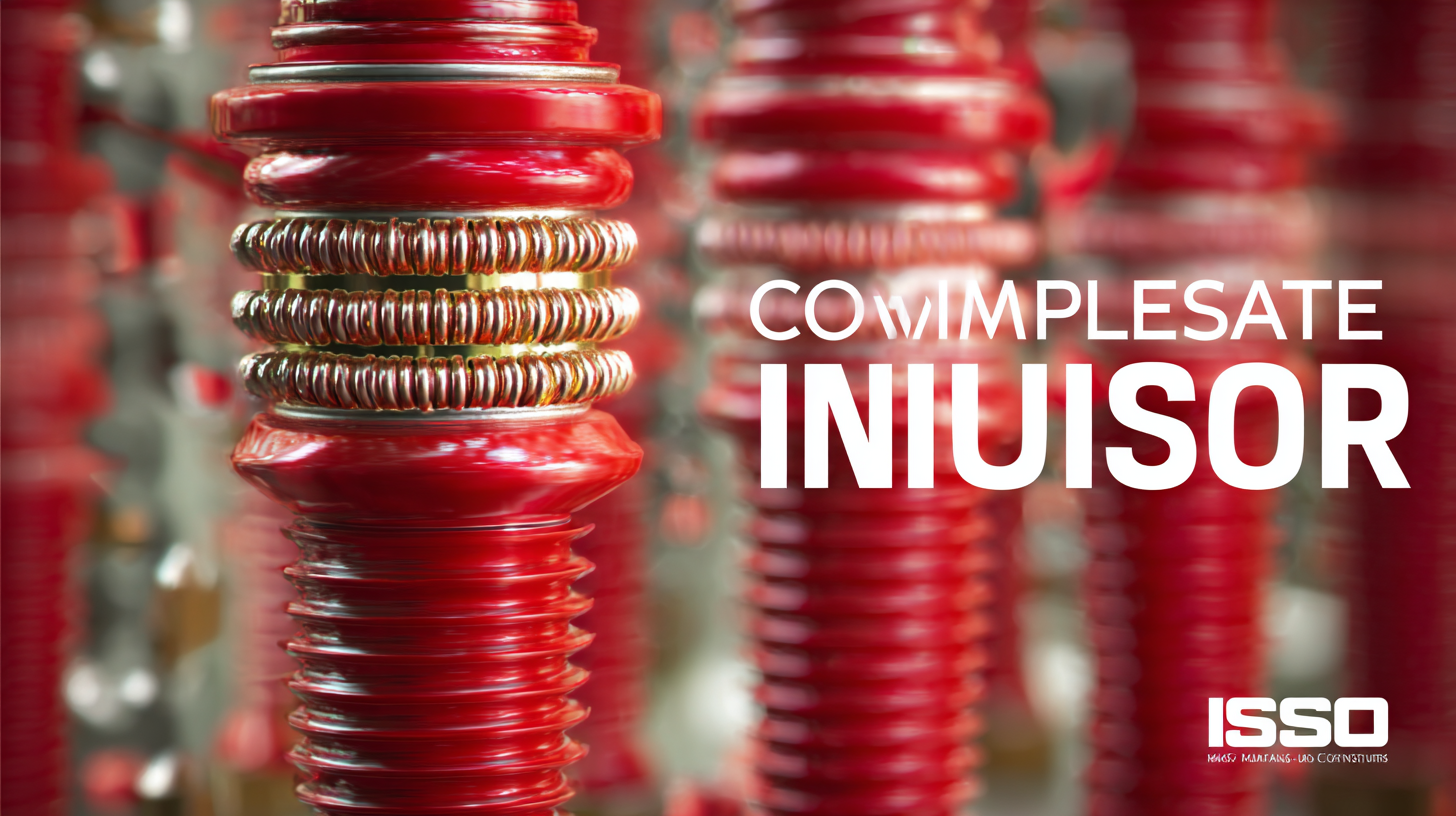

Composite insulators have emerged as a game changer in power transmission, offering significant advancements over traditional materials. As the demand for reliable and efficient energy distribution grows, these innovative insulators, made of materials like fiberglass and silicone, are proving to be more durable and weather-resistant. Their lightweight nature not only facilitates easier installation but also reduces transportation costs, making them an appealing choice for utility companies worldwide.

Tip: When considering composite insulators, ensure to examine the specific environmental conditions they will face. Different designs might be optimized for high humidity, extreme temperatures, or pollution-heavy areas, providing tailored solutions for varied infrastructure needs.

Furthermore, the rise of composite insulators has introduced enhanced performance metrics. They exhibit superior electrical performance and lower leakage current, significantly mitigating the risk of system failures. Their ability to maintain integrity under high voltage and adverse conditions makes them a preferred choice across the industry.

Tip: Regular maintenance of composite insulators is crucial for sustained performance. Schedule periodic inspections to identify any potential wear or damage early, ensuring your power transmission remains uninterrupted and efficient.

China has established itself as a premier manufacturer of composite insulators, recognized for much more than just competitive pricing. The quality of these insulators is largely determined by several key features: material composition, electrical performance, and mechanical strength. According to a report by the International Electrotechnical Commission (IEC), composite insulators can exhibit a significantly higher resistance to pollution and moisture compared to traditional ceramic insulators, enhancing their performance in challenging environments.

One of the standout characteristics of high-quality composite insulators is their use of advanced polymer materials. These materials are engineered to provide excellent hydrophobic properties, which prevent water accumulation and ensure consistent electrical performance. The resilience of these insulators, demonstrated by their mechanical strength, allows them to withstand extreme conditions, a factor emphasized by research from the Electric Power Research Institute (EPRI), showing that composite insulators have a lifespan extending beyond 30 years under typical operating conditions.

**Tip:** When selecting composite insulators, consider the specific environmental conditions they will face, such as pollution levels and temperature fluctuations. Additionally, verify that the insulators meet or exceed international standards, such as those set by the IEC. Regular maintenance and inspection can also significantly extend their lifespan and reliability.

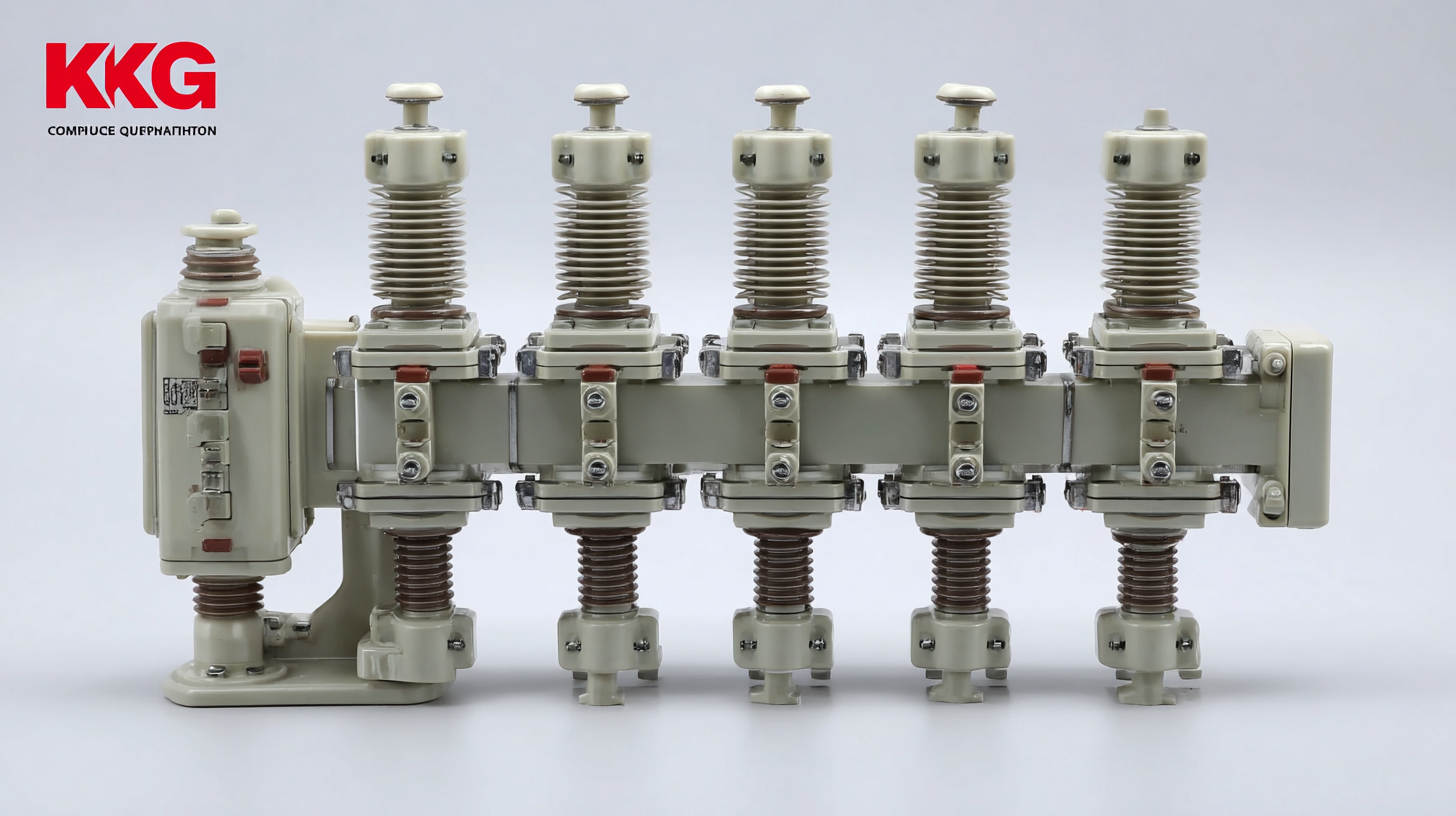

The global composite insulator market is experiencing remarkable growth, driven in large part by the advancements and expertise of manufacturers in China. As the world shifts towards renewable energy sources and modernizes its electrical grids, the demand for high-quality composite insulators is surging. Chinese manufacturers have positioned themselves as leaders in this domain, taking advantage of their advanced manufacturing techniques and cost-effectiveness to cater to a global clientele. This has not only revolutionized their production capabilities but also set new standards for quality and reliability in insulators.

Furthermore, the ongoing transition to renewable energy is creating lucrative opportunities within the composite insulator market, expected to reach $5.6 billion by 2032 at a CAGR of 4.3%. With increasing investments in infrastructure and smart grid technologies, the importance of durable and efficient insulators has never been greater. China's leading manufacturers are leveraging their innovative approaches and economies of scale to dominate the market, ensuring that they meet the evolving needs of energy producers and distributors worldwide. This dynamic environment portrays a significant shift toward a more sustainable and technologically advanced future for energy transmission.

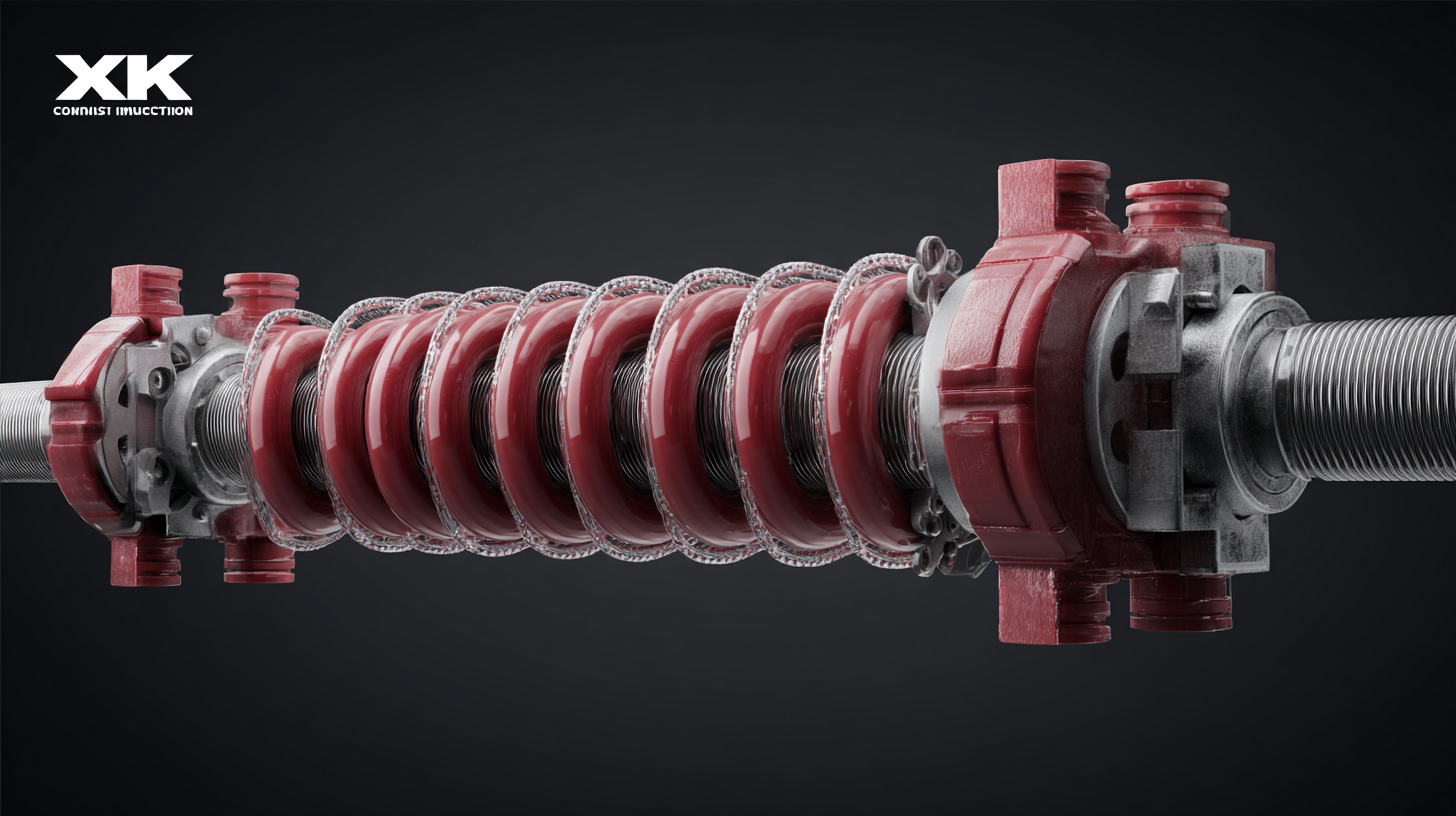

The future of composite insulators in China is increasingly being shaped by sustainability and innovation, pivotal elements driving advancements across various industries. With the growing concern for environmental preservation, manufacturers are exploring biobased materials and prefabrication techniques that contribute to a low-carbon future. This shift not only enhances the production process but also ensures that the composite insulators produced are more eco-friendly, harnessing renewable resources and minimizing waste.

Additionally, the integration of cutting-edge materials such as graphene into composite manufacturing is revolutionizing the field. Graphene's remarkable strength and lightweight properties provide a significant advantage, making it an ideal reinforcement material for composite insulators. As the market for composite insulators is projected to expand significantly, embracing innovative approaches and sustainable materials will play a crucial role in meeting the evolving demands of the industry, ultimately leading to a more resilient and responsible infrastructure.

| Insulator Type | Voltage Rating (kV) | Material Used | Weight (kg) | Eco-Friendly Rating |

|---|---|---|---|---|

| Composite Insulator A | 110 | Silicone rubber | 20 | High |

| Composite Insulator B | 220 | Polypropylene | 25 | Medium |

| Composite Insulator C | 330 | Epoxy resin | 30 | Very High |

| Composite Insulator D | 500 | Fiberglass | 40 | High |

In recent years, China's leading manufacturers have made significant strides in the international market with their high-quality composite insulators. These advancements are not merely about product innovation but reflect a broader transformation in China’s export landscape. The success stories from these manufacturers showcase their ability to meet stringent international standards, thereby opening doors to new markets previously considered inaccessible.

Moreover, the evolving global landscape highlights a shift from merely exporting basic goods to establishing a reputation built on quality and reliability. Similar to the burgeoning biopharmaceutical and gaming industries, where Chinese companies are successfully venturing abroad, the composite insulator sector illustrates how quality assurance can serve as a critical factor for global expansion. Just as innovative drugs and engaging gaming experiences are making waves internationally, high-performance insulators are critical components in maintaining the integrity of power systems. These developments signal a bright future for Chinese manufacturers in the global arena, translating quality into successful international partnerships.