Leave Your Message

In the realm of electrical engineering, the importance of reliable components cannot be overstated. One such fundamental element is the Electrical Standoff Insulator, a device that plays a critical role in ensuring safety and efficiency in various applications. According to Dr. John Miller, a leading expert in electrical insulating technologies, "Electrical Standoff Insulators are pivotal in maintaining the integrity of electrical systems by providing secure connections and preventing short circuits." His insights underscore the necessity of these insulators in safeguarding both equipment and personnel.

The advantages of using Electrical Standoff Insulators extend beyond mere functionality; they also enhance the durability and performance of electrical installations. By providing adequate spacing and protection from environmental factors, these insulators contribute significantly to the longevity of electrical components. Moreover, their robust design allows them to withstand challenging conditions, making them an ideal choice for a wide range of projects.

As the demand for innovative electrical solutions grows, understanding the benefits of Electrical Standoff Insulators becomes increasingly essential for engineers and project managers. This article will explore the top advantages of incorporating these critical components into your projects, highlighting how they can ultimately lead to safer and more efficient electrical systems.

Electrical standoff insulators are crucial components in various applications, providing enhanced electrical isolation and support for components in complex systems. These insulators help prevent arcing and short-circuiting, which are common challenges in electrical engineering. According to a recent report by the International Electrotechnical Commission, proper use of electrical insulation can reduce equipment failure rates by up to 50%, underscoring the importance of quality insulators in project design.

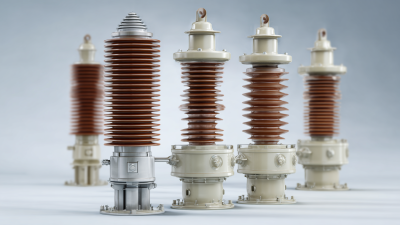

The design of electrical standoff insulators typically involves materials such as ceramics, plastics, and glass, which possess high dielectric strength. The properties of these materials contribute to their effectiveness in withstanding voltage spikes and preventing electrical discharge. As outlined in the IEEE Standards Association publications, the dielectric strength of these materials can reach up to 30 kV/mm, making them suitable for high-voltage applications in sectors including telecommunications, power distribution, and aerospace. Furthermore, they are crucial in supporting circuit boards and components, ensuring structural integrity and operational reliability even under extreme conditions.

Electrical standoff insulators play a crucial role in enhancing the safety and efficiency of electrical projects. One of the key advantages of using these insulators is their ability to maintain proper spacing between conductive components, which helps prevent short circuits and electrical arcing. By isolating electrical parts, standoff insulators ensure that voltage differentials do not compromise system integrity, thus prolonging the lifespan of equipment and reducing maintenance costs.

Furthermore, electrical standoff insulators contribute to improved thermal management in electrical systems. They possess excellent thermal resistance properties, which help dissipate heat generated by electrical components. This characteristic is essential in preventing overheating, which can lead to system failures. As a result, utilizing standoff insulators can enhance the overall performance and reliability of electrical projects, making them an indispensable choice for engineers and project managers looking to optimize their designs.

| Benefit | Description | Applications | Key Material Characteristics |

|---|---|---|---|

| Electrical Isolation | Prevents electrical short circuits by providing distance between conductive parts. | Circuit boards, power supplies, and various electronic devices. | High dielectric strength and resistance to electrical breakdown. |

| Vibration Resistance | Reduces the impact of vibrations on electrical components, prolonging their lifespan. | Automotive, aerospace, and industrial machinery applications. | Flexible yet robust materials that absorb shock. |

| Thermal Management | Helps dissipate heat away from sensitive components. | Power electronics, LED lighting systems, and high-performance computers. | Materials with high thermal conductivity. |

| Flexibility in Design | Offers design engineers more options for layout and spacing of components. | Custom electronic assemblies and modular systems. | Available in various shapes and sizes to suit specific project needs. |

Electrical standoff insulators are essential components utilized across various industries, providing crucial support and insulation for electrical systems. In the telecommunications sector, these insulators facilitate the safe transmission of signals by maintaining a secure distance between energized components, which helps prevent shorts and ensures reliable communication. Their robust design allows them to withstand harsh environmental conditions, making them ideal for outdoor installations, such as cell towers and antenna systems.

In the renewable energy field, electrical standoff insulators play a significant role in supporting solar panels and wind turbines. They are vital for maintaining the integrity of electrical connections while ensuring safety from electrical hazards. These insulators help in minimizing the risk of electric shock to personnel working on or near these systems. Additionally, in the automotive and aerospace industries, standoff insulators are employed in various electrical assemblies, providing stability and protection against vibration and moisture, thus enhancing the durability and performance of critical systems.

When comparing electrical standoff insulators with traditional insulation methods, it’s essential to highlight the key distinctions that make standoff insulators a preferred choice in many projects. Traditional insulation methods often rely on materials that can deteriorate over time, leading to potential failures and safety hazards. In contrast, electrical standoff insulators are designed to provide superior durability and stability, ensuring long-term performance even in challenging environments. Their robust design allows for effective separation between electrical components, reducing the risk of short circuits and enhancing overall system reliability.

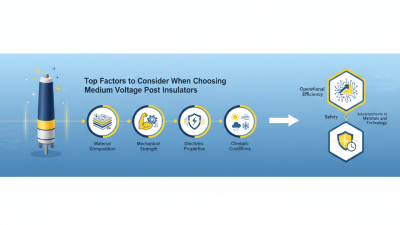

Tips for selecting the right standoff insulators include considering the voltage rating, environmental conditions, and the specific mechanical requirements of your project. Ensure that the materials used in the standoff insulator are compatible with the electrical applications to prevent unforeseen complications. Moreover, assessing the thermal performance of the insulator can be crucial in environments prone to high temperatures, ensuring optimal functionality over time.

Another point of comparison is the installation process. Traditional insulation methods can often be cumbersome and time-consuming, requiring extensive preparation and labor. In contrast, electrical standoff insulators typically simplify installation, allowing for quicker project timelines without compromising on safety or effectiveness. Evaluate the ease of integration with existing systems, which can save both time and resources during project execution.

Implementing electrical standoff insulators effectively requires careful consideration of the application environment and the specific requirements of the project. One best practice is to ensure proper selection based on voltage levels and environmental factors. According to the International Electrotechnical Commission (IEC), the dielectric strength of common insulator materials varies significantly, impacting their performance under high voltage conditions. Selecting a material with adequate dielectric strength helps prevent electrical breakdown, ensuring system reliability. For instance, ceramic insulators, which offer superior thermal stability and aging resistance, may be favored in outdoor applications where exposure to moisture and thermal cycling is common.

Another critical aspect is the installation method. Adhering to proper spacing guidelines is vital to maintaining effective electrical performance. The Institute of Electrical and Electronics Engineers (IEEE) notes that incorrect spacing can lead to arcing and insulation failure, particularly in high-voltage systems. Utilizing recommended spacing not only enhances safety but also reduces maintenance costs associated with premature failure. Furthermore, regular inspections and adherence to manufacturer installation guidelines can optimize the operational lifespan of the insulators. By incorporating these best practices, engineers can ensure that electrical standoff insulators perform optimally, thereby increasing the overall efficiency and safety of electrical systems.