Leave Your Message

Bmc Insulators are gaining attention in the electrical industry for their unique properties. According to recent market research by GlobalData, the demand for high-performance insulators is projected to grow by over 7% annually through 2025. This growth is largely fueled by innovations in materials like BMC, or Bulk Molding Compound.

Dr. Emily Rogers, an expert in electrical materials, once stated, “BMC Insulators not only enhance performance but also provide long-term reliability.” Their excellent thermal resistance and mechanical strength make them ideal for a variety of applications. BMC Insulators effectively handle high-voltage environments while minimizing energy loss.

However, while BMC Insulators demonstrate promising benefits, challenges remain. Production consistency and long-term material performance must be continually assessed. The industry must reflect on how to balance innovation with quality control to fully realize the potential of BMC Insulators in electrical applications.

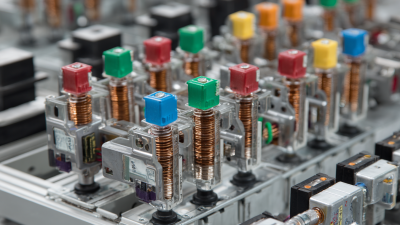

BMC insulators have become increasingly important in electrical applications. These composite materials offer high strength and durability. They are often used to insulate and protect conductive components in electrical systems. With their excellent thermal stability, BMC insulators can withstand extreme temperatures. This property makes them suitable for outdoor environments as well.

In electrical applications, BMC insulators enhance safety and reliability. They resist moisture and chemicals, reducing the risk of failures. Users often appreciate their lightweight nature, which helps in installation. However, it's essential to handle them with care during installation. Improper handling may lead to material damage.

Tips: Always check the specifications of your BMC insulator. Ensure they match your application needs. Regular maintenance checks can identify issues early on. Proper maintenance prolongs the life of these critical components. Using protective gear during installation is also crucial for safety. Remember, while BMC insulators are strong, they require attention to detail to function optimally.

BMC insulators play a crucial role in electrical applications. They provide excellent insulation properties. This makes them suitable for various components in electrical systems. Their lightweight nature helps in easy installation and transportation. Moreover, the chemical resistance of BMC insulators extends their lifespan. They can withstand harsh environmental conditions, ensuring reliability.

When using BMC insulators, proper installation is key. Over-tightening screws can damage the material. This can lead to reduced effectiveness. It’s also important to check for cracks regularly. Regular maintenance ensures long-term performance.

Consider the temperature range of your application. BMC insulators can perform in extreme temperatures. But exceeding their limits can lead to failure. Always follow the manufacturer's guidelines. This helps in optimizing the performance of your electrical systems. Choosing the right insulator is vital for safety and efficiency.

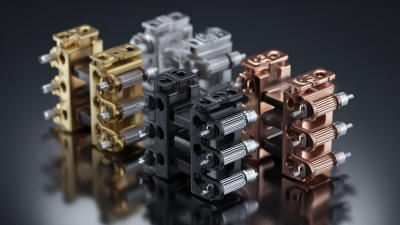

| Benefit/Use | Description |

|---|---|

| High dielectric strength | BMC insulators offer excellent electrical insulation properties, ensuring high dielectric strength for safety and reliability in electrical applications. |

| Thermal stability | These materials maintain their insulating properties over a wide temperature range, preventing degradation in high-heat environments. |

| Chemical resistance | BMC insulators resist many corrosive substances, making them suitable for various industrial environments. |

| Lightweight | Their lightweight nature simplifies handling and installation, reducing overall project costs. |

| Versatile application | BMC insulators can be used in various electrical components such as switchgear, transformers, and outdoor electrical equipment. |

| Reduced electrical losses | They help minimize energy losses by maintaining optimal insulation properties, contributing to overall system efficiency. |

| Low moisture absorption | These materials exhibit low moisture absorption rates, enhancing their durability and performance in humid environments. |

| Enhanced mechanical strength | BMC insulators provide high mechanical strength, resulting in better performance under mechanical stress. |

| Cost-effective solution | They offer a cost-effective alternative to traditional insulation materials while maintaining essential performance characteristics. |

| Environmental sustainability | BMC materials are often recyclable, making them a more environmentally friendly choice compared to other insulation types. |

BMC insulators are crucial for power distribution systems. They provide excellent electrical insulation properties. This type of insulation helps in preventing short circuits and electrical faults. Their lightweight nature is a significant advantage, making transportation and installation easier.

In substations and power lines, BMC insulators play a key role. They resist environmental factors like moisture and dust, helping to maintain electrical integrity over time. Their performance in extreme temperatures is noteworthy. However, there are some limitations to consider. For instance, they might not be suitable for every application, and the installation process can sometimes be complex.

Maintenance of BMC insulators requires attention too. Regular inspections are essential to ensure safety. Small cracks can develop over time, which may pose risks. Identifying these issues early can prevent larger problems down the road. Understanding how BMC insulators perform in various conditions is vital for optimal use.

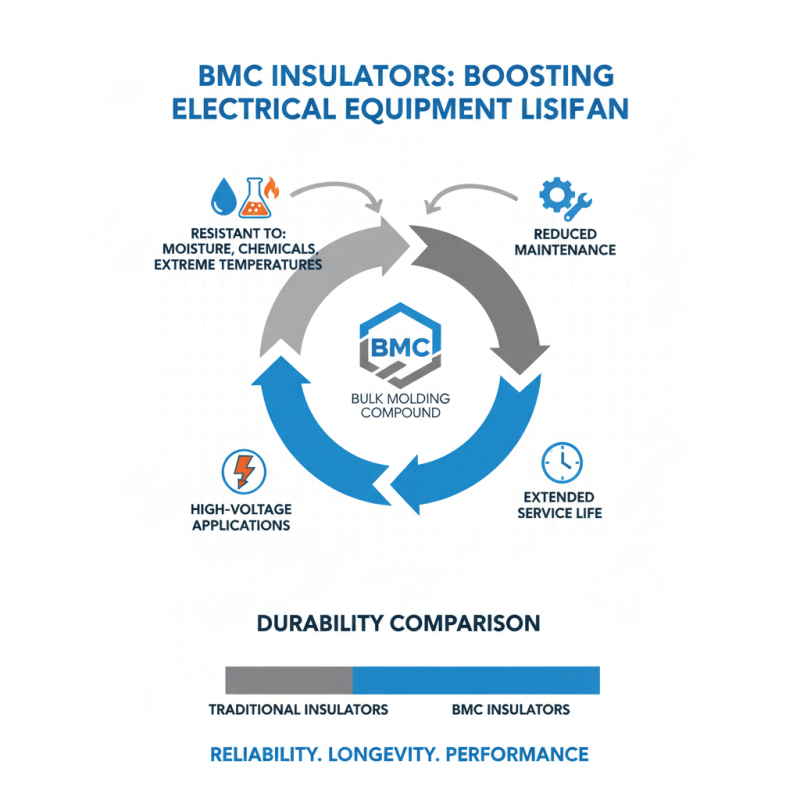

BMC insulators play a crucial role in enhancing the longevity of electrical equipment. Their unique material composition makes them resistant to moisture, chemicals, and extreme temperatures. This resilience directly translates to reduced maintenance needs and longer service life for electrical systems. In environments where traditional insulators may fail, BMC insulators stand strong. They are particularly effective in high-voltage applications.

Tip: Regularly inspect your electrical equipment. Look for signs of wear or damage. Early detection can prevent costly repairs.

Another key benefit is their lightweight nature. This makes handling and installation much easier. However, not all setups may benefit equally. In some cases, the installation requirements may not fully align with the benefits BMC insulators provide. Oversight in these situations can lead to performance issues down the line.

Tip: Choose the right insulator for your application. Consult with professionals to understand the specifics of your setup.

BMC insulators deliver great insulating properties while also ensuring safety. They can handle high stress and high temperatures effectively. Yet, like any material, they have limitations. Understanding these can prevent unexpected failures. Awareness of the environment and specific application needs is essential for optimal performance.

The future of BMC insulators in electrical engineering looks promising. As the demand for efficiency grows, BMC insulators are becoming crucial. They offer excellent thermal stability. This property allows devices to operate better under varying temperatures. Moreover, their lightweight nature makes them ideal for modern designs. Innovative applications are emerging as engineers explore new possibilities.

Sustainability is influencing choices in material design. BMC insulators can be produced using recycled materials. This makes them an eco-friendly option. However, the manufacturing process needs further improvement. There are concerns about production waste and energy consumption. Balancing efficiency with sustainable practices remains a challenge.

Additionally, the integration of smart technologies opens new avenues. BMC insulators can be embedded with sensors. This feature allows real-time monitoring of electrical systems. Yet, the cost of implementing smart features can be high. Finding a balance between cost and innovation is essential for widespread adoption. This evolution in technology represents both opportunities and uncertainties. The path forward will involve continuous learning and adaptation.