Leave Your Message

In recent years, the power utilities sector has increasingly recognized the critical advantages of employing Composite Insulators in their infrastructure. As highlighted in a recent industry report by the International Electrotechnical Commission (IEC), Composite Insulators offer significant benefits over traditional porcelain and glass insulators, including enhanced mechanical strength, reduced weight, and superior resistance to environmental stresses. These characteristics not only improve the reliability of electrical systems but also lower maintenance costs and extend the operational life of insulators, ultimately contributing to a more resilient power grid.

Dr. James Thompson, a leading expert in insulation technology, emphasizes the transformative impact of Composite Insulators on contemporary power utilities. He states, "The transition to composite materials has revolutionized insulator design, allowing for more efficient energy transmission and enhanced durability against harsh conditions." As power utilities seek to modernize their systems and adapt to the increasing demand for reliable energy, the advantages offered by Composite Insulators become even more pronounced. This article delves into the top ten advantages of these innovative insulators, showcasing their potential to optimize performance and drive the future of power distribution.

Composite insulators have emerged as a significant advancement over traditional ceramic and glass insulators, particularly in the realm of power utilities. One primary advantage of composite insulators is their lightweight construction, which facilitates easier handling and installation. This reduces labor costs and the time required for installation, allowing for more efficient project execution. Additionally, their non-porous surfaces minimize the risk of moisture accumulation, significantly reducing the likelihood of operational failures caused by environmental factors such as pollution and severe weather.

Another critical benefit of composite insulators is their superior mechanical strength and resilience. They are less prone to breakage from physical impacts compared to their traditional counterparts, enhancing their durability and longevity. Furthermore, composite materials exhibit excellent electrical properties and can operate effectively across a broader range of temperatures. This versatility ensures that power utilities can rely on these insulators even under extreme conditions, making them an ideal choice for modern energy infrastructure. The evolution from traditional insulators to composite alternatives marks a significant step forward in ensuring reliability and efficiency in power transmission systems.

Composite insulators have emerged as a game changer for power utilities, particularly due to their enhanced durability and resistance to various environmental factors. Unlike traditional porcelain or glass insulators, composite insulators are manufactured with advanced materials that can withstand harsh conditions such as extreme temperatures, humidity, and UV radiation. This resilience not only translates into longer service life but also reduces the frequency of maintenance and replacement, leading to significant cost savings for utilities.

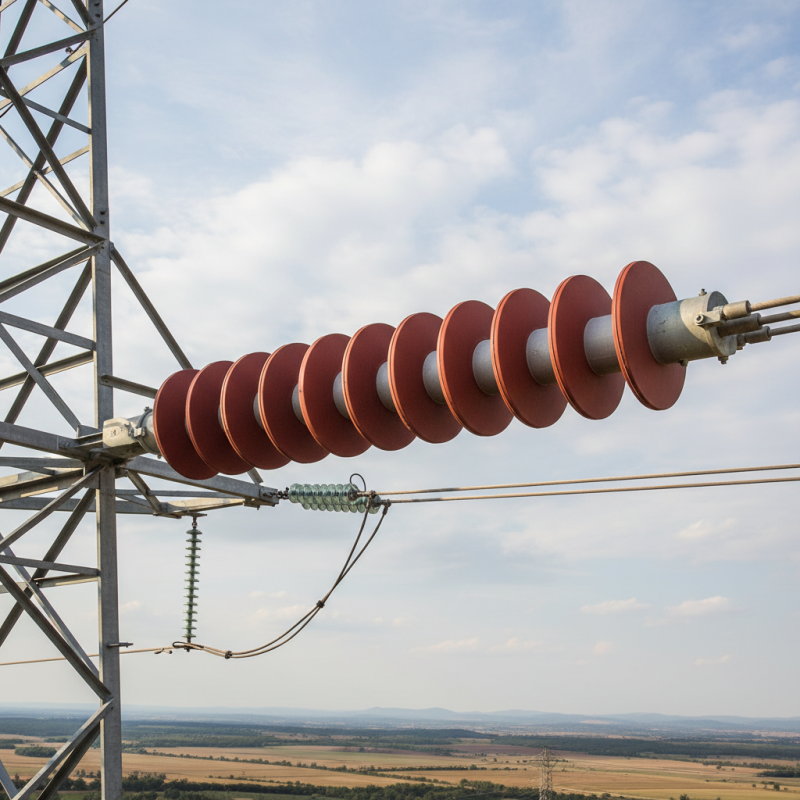

Incorporating composite insulators into power systems can greatly improve reliability. Their lightweight nature allows for easier installation and less infrastructure stress compared to heavier alternatives. Additionally, these insulators are less susceptible to breakage from environmental impacts, such as ice loading or wind forces, making them ideal for regions prone to severe weather conditions.

Tips for utilities considering the switch to composite insulators include thoroughly evaluating the local environmental conditions and assessing the potential impact on long-term operational performance. It’s crucial to train maintenance personnel on the unique properties of these insulators to ensure they are handled properly. Moreover, investing in research and development to customize composite materials can further enhance their effectiveness in specific applications, contributing to a more robust power distribution network.

Composite insulators have emerged as a transformative solution for power utilities, particularly due to their significant reduction in maintenance costs and their enhanced reliability. Unlike traditional ceramic or glass insulators, composite materials offer exceptional durability and resistance to environmental factors such as pollution, UV radiation, and thermal cycling. This resilience translates into fewer breakdowns and less frequent need for replacements, ultimately driving down maintenance expenses. Utilities can allocate these saved resources toward improving infrastructure and services, contributing to a more efficient operation overall.

Moreover, the reliability of composite insulators means that power utilities can experience fewer outages and disruptions. The ability of these insulators to perform effectively under varying climatic conditions ensures a more stable supply of electricity. As reliability is paramount in power distribution, the use of composite insulators can significantly enhance system performance. With their superior characteristics, utilities are equipped to maintain a consistent service quality, minimizing the risks associated with equipment failure and enhancing overall customer satisfaction. This makes composite insulators not just a cost-saving measure but a strategic investment in the future of power utility operations.

This chart illustrates the key advantages of composite insulators for power utilities, highlighting the reduction in maintenance costs and improved reliability.

Composite insulators have garnered significant attention in the power utilities sector due to their lightweight design, which greatly enhances installation and handling efficiency. According to a report from the International Energy Agency, the average weight of composite insulators is approximately 50% less than that of traditional ceramic insulators. This substantial reduction in weight not only simplifies transportation but also enables easier handling during installation, thereby minimizing labor costs and time. Utility companies can benefit greatly from the ability to use less heavy equipment and reduced manpower, leading to faster project completions and improved overall productivity.

Additionally, the lighter design of composite insulators contributes to safety in various operational environments. Studies indicate that reduced weight leads to decreased overall stress on supporting structures, which can prolong their lifespan and reduce the likelihood of structural failures. Moreover, with the industry's increasing emphasis on safety regulations, lighter materials can ease compliance by facilitating safer working conditions for installation crews. The adoption of composite insulators can also result in a 30% reduction in installation time, as reported by the Electric Power Research Institute, showcasing their clear advantages in modern power utility operations.

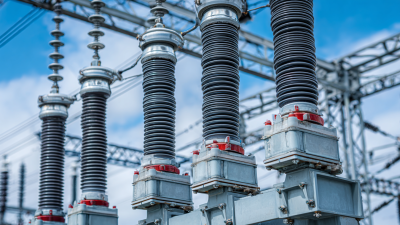

Composite insulators have emerged as a favored choice in high voltage applications, offering numerous electromechanical performance benefits that are vital for the reliability and efficiency of power utilities. One of the key advantages of composite insulators is their lightweight design, which facilitates easier handling and installation. This feature significantly reduces the mechanical stress on supporting structures, allowing utilities to optimize their infrastructure and enhance overall system stability. Additionally, the materials used in composite insulators offer superior resistance to environmental stresses, including UV radiation and pollution, ensuring that they maintain their performance over extended periods in various climatic conditions.

Another important performance benefit lies in the exceptional electrical characteristics of composite insulators. Their hydrophobic properties minimize water absorption, drastically reducing the risk of electrical tracking and flashover, which can lead to outages and equipment damage. Furthermore, composite insulators exhibit excellent flexibility and shock absorption capabilities, contributing to their resilience against extreme weather conditions and mechanical impacts. This combination of lightweight design, durability, and outstanding electrical performance makes composite insulators an ideal solution for modern high voltage systems, enhancing safety and operational efficiency for power utilities.